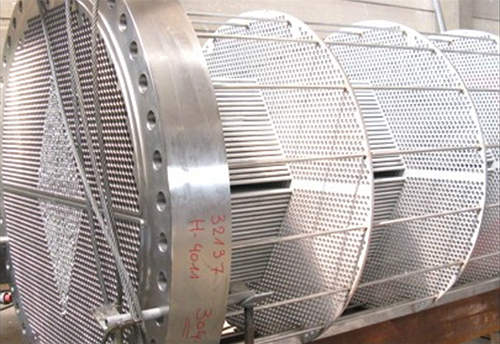

Vigor Kristiansund is one of the leading fabricators of advanced pressure vessels for the Norwegian oil and gas industry.

We provide EPC (engineering, procurement, construction) services for offshore and subsea industries and companies.

With the ability to offer closely integrated engineering and fabrication, we follow projects all the way from design stage to finished product.

Vigor Kristiansund has about 40 dedicated employees with extensive experience in design, engineering and fabrication of complicated structures and materials.

We specialize in providing steel, aluminium and titanium structures, pressure tanks, processing equipment, tie-in spools and subsea equipment.

Since 1972 Vigor Kristiansund has delivered innovative solutions for the offshore and maritime industries.

Vigor Kristiansund performs mechanical design calculations, analysis of vessels or shell and tube heat exchangers, for use in a wide range of applications.

Our designs are completed in compliance with the latest editions of international codes and standards, such as:

- The European code for unfired pressure vessels / EN-13445

- BS Codes / PD 5500

- DNV Rules for Pressure Vessels

- ASME Boiler and Pressure Vessel Design Code

- AD 2000 Code of practice for pressure vessels

- Tubular Exchanger Manufacturers Association (TEMA)

- API standards and regulations

We also perform services including:

- Simulation and analysis of separate components

- Analysis of operation under wind or seismic conditions

- Analysis for horizontal shipping of vertical vessels

We use various software tools to perform engineering work, according to project requirements.

Design tools we use include:

- OhmTech Visual Vessel Design

- Intergraph PV Elite

- Euresearch Microprotol

- PRG NozzlePro

- Intergraph CAESAR II

Detailed engineering

After preliminary design has been successfully concluded and approved, we continue with the detailed engineering phase. In this step, products are completely outlines using solid modeling and drawings, while the complete bill for materials is issued for purchase.

This stage also includes:

Cost and schedule control

Specification of test requirements

Fabrication follow-up

Drafting

We provide 3D modeling solutions for any type of product and component in the oil and gas industry. We use the latest standards and techniques in 3D modeling to develop mechanical models. We can create a new 3D model from a concept, or convert an existing 2D mechanical design to a 3D model – whichever meets your need in the best manner.

Simulation

For basic (static) loads, equipment can be designed safely according to calculation methods provided in various design codes.

For more specific vessel design problems (such as calculating local stresses due to the combined internal pressure and external nozzle loadings, or for evaluation of cyclic loads) classical calculations often do not apply.

For such challenging design problems, Vigor Kristiansund uses FEA and simulation software tools (Inventor Professional, Autodesk Simulation, ANSYS) to complete the task.

Various loads can be included in the analysis, including:

- Thermal

- Weight

- Operating

- Occasional

- Pressure

- Wind

- Earthquake

Simulation can be used for:

- Entire structures

- Components

- Nozzles

- Lifting devices

- Supports

- Conical, dished and spherical heads

Piping

Piping stress and flexibility analysis is carried out in order to ensure that the layout of piping and pipe supports will not fail under any load, or combination of loads, in the system. For piping design rules and flexibility analysis we use various design codes, such as:

- The European code for metallic industrial piping / EN-13480

- ASME code for power piping B31.1

- ASME code for process piping B31.3

- ISO 15649 Petroleum and natural gas industries – Piping

- API standards and regulations

Quality assurance and health, safety and environment

Vigor has had an implemented HSE management system and a quality assurance program, according to NS-EN-ISO 9001:2000.

A couple of years ago we decided to start the certification process for a management system in conformity with NS-EN ISO 9001:2008 and ISO 3834-2 for fusion welding of metallic materials.

Both certificates were issued by Teknologisk Institutt on 15th of February 2013.

The management system (EQS from Extend AS) is web-based and clients may be given direct access

Vigor is qualified in the Achilles Joint Qualification System for several product and service categories, with Achilles Id. 22986. The last audit was performed by Achilles in November 2012.

Summary

Vigor’s capabilities

- Fabrication of advanced equipment

- Engineering, procurement and construction services

- Design, analysis and engineering of pressure vessels and process equipment

Vigor’s engineering tools

- Autodesk Inventor Professional Simulation

- Autodesk Design Suite Ultimate

- OhmTech VVD

- Intergraph PV Elite

- Euresearch Microprotol

- PRG NozzlePro

- Intergraph CAESAR II

Vigor’s products

- Pressure tanks

- Subsea structures

- Tie-in spools

- Offshore containers

- Spreader bars

- Pig receivers / launchers

- Heat exchangers

- Processing equipment