Falck Fire Consulting (FFC) is an independent fire-protection consultancy, providing a unique range of services to assist in developing and implementing cost-effective and relevant fire and explosion hazard management (FEHM) strategies.

Fire-Protection Consultancy for the Offshore Sector

FFC works primarily in the offshore and petrochemical sectors, and across a wide range of other high-risk industrial and commercial facilities. Our scope of services includes FEHM strategy development, fire risk assessment, fire and gas-detection and protection system specification and design, factory and on-site inspection and testing of equipment, and development of emergency response plans (ERPs).

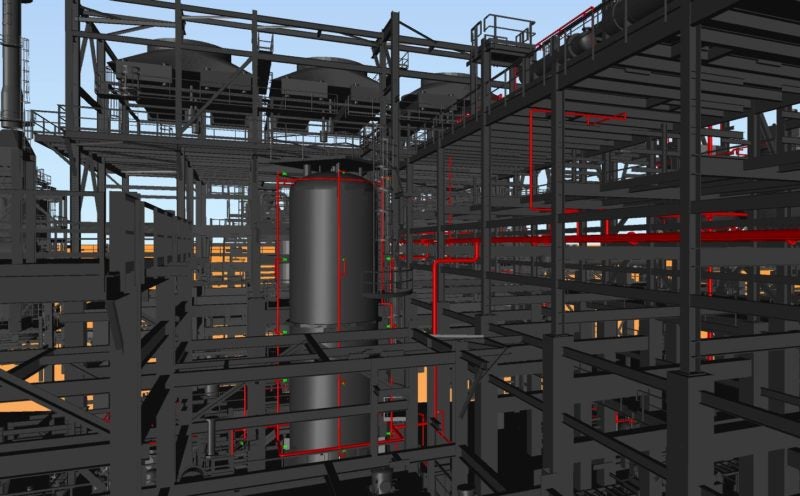

Additional services include conceptual, schematic and detailed sprinkler system design, including 3D drawing capability, tender appraisals, installation inspections during construction and technical dispute resolution.

Fire and Explosion Hazard Management (FEHM)

FFC has been instrumental in the development of two key philosophies to assist clients in managing on-site risks. The first of these is FEHM, which uses a logical staged approach to develop effective protection measures.

Stage one is the identification of credible fire scenarios using various input tools, such as on-site hazardous materials and likely ignition sources. The scenario consequences are also studied with consideration given to life safety, environmental impact and asset value.

Stage two compares risk-reduction options by evaluating alternative prevention, protection and mitigation measures.

Stage three defines and formalises the fire hazard management policy, while stage four is the implementation stage, which includes maintenance, training and policy updates.

Fire Systems Integrity Assurance (FSIA)

The second philosophy is fire systems integrity assurance (FSIA), which was developed by FFC in cooperation with the Association of Oil and Gas Producers. FSIA specifies an auditable, structured approach to ensure that fire systems perform their defined, appropriate role whenever required. This document was developed following the oil industry’s recognition that fire systems are very often not designed, commissioned, tested and maintained correctly.

FSIA follows a similar logical process to FEHM but with greater emphasis placed on equipment specifications, performance criteria and maintenance and testing regimes. The FSIA document is in the public domain at www.ogp.org.uk.

Fire-Suppression Systems

FFC has designed fire-protection and fire and gas-detection systems both on and offshore for many national and international companies.

Additional designs have included sprinkler, detection and standpipe systems in storage facilities, office buildings, hotels, shopping precincts and industrial complexes, yard mains and hydrant systems, high and low-expansion foam systems, medium and high-velocity water-spray systems, and gas and dry powder systems.

Fire Hazard Management Seminars

FFC has developed, run and delivered numerous specialist seminars on an international basis. These have been held as both open and in-house events with representatives of more than 70 companies attending. Typical locations have included Abu Dhabi and Dubai, UAE; Kuwait; Singapore; Kuala Lumpur, Malaysia; Bangkok, Thailand; France; Norway; and the UK. These seminars have included:

- Liquefied natural gas (LNG) fire hazard management

- Fire and gas-detection principles

- Storage tank fire hazard management

- Emergency planning

- Fire systems integrity assurance

- Gaseous fire-extinguishing agent system design and operation

- Foam systems application and design

Energy Institute

FFC developed the revised Model Code of Safe Practice Part 19 for Fire Precautions at Petroleum Refineries and Bulk Storage Installations, which was published in 2012.

FFC also authored the fire-protection chapter of the Energy Institute (EI) guidance document on the use of ethanol at petroleum distribution installations.

Building Research Establishment

FFC developed the Handbook for Sprinkler Systems in accordance with the Loss Prevention Council (LPC). This report is intended as an aid to understanding fire sprinkler installations and the LPC rules to which they are designed. It explains the engineering behind the rules and regulations, as well as some common misunderstandings about sprinkler systems.

Storage Terminal Audits

FFC has carried out numerous terminal audits for a number of companies, including BP, Exxon Mobil, Shell, BP, Q8, Texaco, Vopak, Sasol, Zadco, QP and Nexen. These have taken place in a number of countries, including the UK, Netherlands, France, Germany, Italy, Norway, Sweden, Denmark, Belgium, Hong Kong, UAE, Kuwait, China, Russia, Lithuania, Estonia, Turkey, Croatia, India, Kazakhstan, Ghana and many more. FFC is therefore familiar with worldwide fire-prevention practices under various operating conditions.

LASTFIRE

FFC, operating as Resource Protection International (RPI), is a coordinator for the Lastfire group. This is a consortium of sixteen oil companies reviewing the fire risk associated with atmospheric storage tanks. More details of this can be found at www.lastfire.org.uk.

About FFC

FFC is the combination of two internationally recognised and respected consultancies, RPI and Frontline Fire International (FFI). This has created a unique team with wide experience over the last twenty years. Please use the form below to contact us with your enquiry.