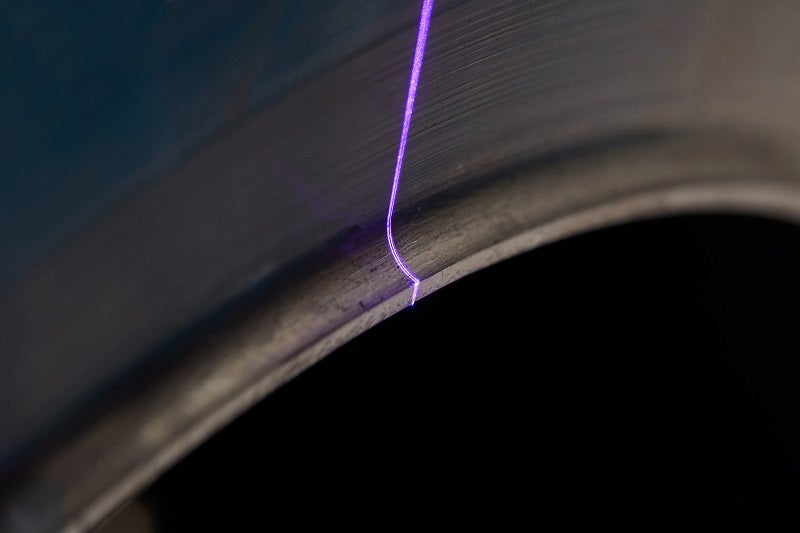

Understanding and verifying pipe bevel geometry is a vital quality control step prior to fit-up of oil and gas pipelines with tight project tolerances. While Vernier calipers or radius gauges have been traditionally used to provide dimensional feedback, these methods have proven time-consuming and limited in their practical application. Presenting his paper, entitled The Importance of Pipe Bevel Geometry, at this year’s Subsea Asia event (29 November – 2 December) Alex Felce, technical reporting manager at OMS, will examine the growing use of new laser-based technology in this field.

Given the economic pressures still felt within the oil and gas industry, Felce believes that this new generation of laser scanning tools are paving the way for increased pipeline integrity through advanced measurement technology.

The operation of a new laser bevel measurement tool is described in the seminar and the way in which it can be applied in real-word conditions is discussed. Also included are the range of bevel types and numerous features that require consideration by the pipeline construction workforce.

Felce said: "Our experience shows that better control of pipe bevel geometry can lead to improved weld quality and superior pipeline integrity for oil and gas operators. The potential for huge cost-saving through better process efficiencies and fewer cut-outs is undoubtedly a major consideration for the sector in such a turbulent market."