Norway is keen to curb its carbon emissions. Under the Kyoto protocol period 2013-2020 it is committed to reducing carbon emissions by at least 30% below 1990 levels with another 10% being cut by 2030. With an abundance of existing renewable energy resource, and more set to come online, Norway’s transition to a low carbon economy is technically feasible. However, with such a huge economic reliance on oil from the Norwegian Continental Shelf, a wholesale move to renewables is just not possible.

Consequently, the government and the state-owned oil fund, has set ambitious targets for the offshore industry to make the exploration and production of oil in the region less carbon intensive. With current estimates putting the contribution of the offshore oil industry at 25% of all of the country’s emissions, significantly reducing the environmental impact of production has the potential to pay big dividends.

Taking a leading role in this pursuit is the majority state-owned oil and gas company Statoil, which is aiming to reduce climate gas emissions by 80%-90% compared with standard operations with its landmark Johan Sverdrup oil field.

As Statoil itself has said, the project holds ‘gigantic potential’. With expected resources of up to 3 billion barrels of oil, it stands as one of the biggest ever discoveries on the Norwegian continental shelf and is forecast to deliver significant economic value for half a century. For Statoil, it is expected to bring in NOK 1.350 billion while the Norwegian government will take NOK 670 billion in tax revenues over its lifetime. Slated to come online in 2019, production is expected to peak at 650,000 barrels per day.

See Also:

A bold approach to operational power

But with pressure growing both at home and internationally for tighter environmental stewardship and action to reduce carbon emissions, such a project cannot simply get by with a ‘business as usual’ approach.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData"Through some 40 years in the oil business we’ve set lots of technological world records," said Kjetel Digre, Statoil’s project director of Johan Sverdrup Facilities. "For the gigantic Johan Sverdrup it is essential that we repeat old successes, and also find more efficient solutions."

Norway is in a better position than most countries to deal with turbulent times.

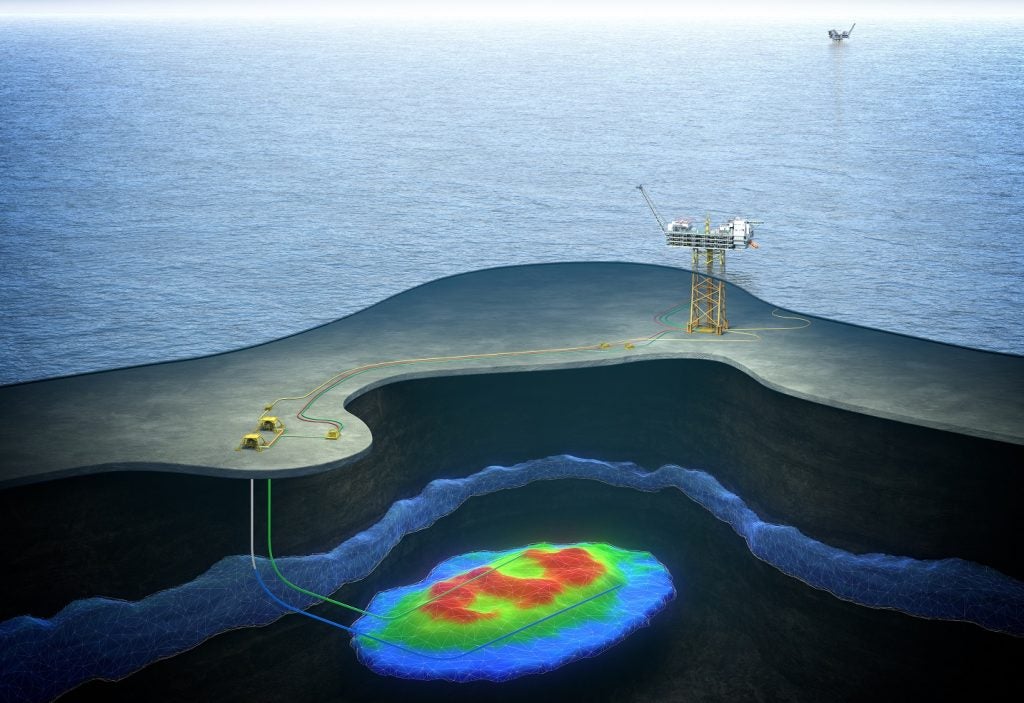

And nowhere in the project is that more important than the provision of power. Encouraged firmly by the government, which has repeatedly called for those operating in the NCS to decarbonise, Statoil has pledged to source all of the power required for operations directly from the national grid rather than the typical operational approach of using onsite gas turbines.

Instead, the company has contracted global power specialist ABB to provide the infrastructure to deliver onshore power to the platform through undersea cables. The deal, valued at NOK 1billion, will enable power from the Karsto processing station in Tysvaer to travel 200km to the Johan Sverdrup field, with construction beginning in the first half of 2017.

Sending energy 200km underwater

"With power from shore you can go long distances with either AC or DC technology and you can provide renewable energy to a power from shore source or you can have a large gas facility producing power for onshore," said Per Erik Holsten, managing director of oil, gas and chemicals at ABB. "The efficiency of that type of technology is much higher than you would have on a traditional gas turbine generator technology."

While alternating current (AC) transmission is both the more technologically straightforward and cost-effective approach, its performance is severely reduced over long distances. As a result, the transmission technique for Johan Sverdrup will be to convert the power into direct current and transport through HDVC cables via a conversion centre before converting it back into AC at the platform.

"There are two ways to send power offshore," said Svein Knudsen, VP at ABB. "But there is always a limit for AC due to transmission loss. If the power requirement is too big and the distance too far, the only solution is HVDC. The technology of DC is of course more complicated than traditional AC, it has more power electronics but it has been used onshore and offshore since the 1950s, so it is a mature technology that’s continuously developed upwards in power."

Having been used by ABB for more than 60 years, the technology has only recently been adopted as a means of powering offshore platforms and so far its use is exclusive to the North Sea. The upcoming project will be its most ambitious test, but its effectiveness has already been shown at Statoil’s Troll A field and the Valhall field owned by BP.

Building on previous successes in the NCS

At Troll A, HDVC cables are currently delivering 100 MW of electricity from the Kollsnes onshore station to power two compressor drives on the platform and provide the power to carry out operations. In addition to reducing the overall emissions of the operation, the approach also reduces the weight and space taken by the power infrastructure.

Discussing the project, ABB said: "Power from the mainland grid is converted to direct current (DC) in a converter station on the Kollsnes onshore plant, transmitted through a subsea cable and converted back to alternating current in the HDVC module onboard Troll A."

Expanding its use to other offshore areas

The programme does not come without its challenges though. With little room for contingency planning, owing to the expense and technical difficulty of backup cables, any disruption to the cables will cause major issues for operations. To best ensure that disruptions do not occur, a detailed analysis of the subsea conditions will need to be carried out and factored into the cable design.

Older than the constitution of Norway itself, technology company Kongsberg Gruppen is celebrating its 200th anniversary.

A further challenge will come in ensuring there is sufficient power on the mainland grid from which to draw. Due to Norway’s abundance of hydropower, the demand for Johan Sverdrup can be more than met in normal operating conditions, but any disruption to the grid or a spike in demand elsewhere could cause operational issues for Statoil.

Outlining his perspective, Auke Lont, CEO of Norwegian grid operator Statnett, said: ""For the petroleum sector to move on, we think it needs electrifying. Statoil’s vision is platforms on the bottom of the sea, where there is not much space for large gas turbines, so you need electricity."

As Statoil has said, using power from onshore for a project as ambitious and demanding as Johan Sverdrup will take something ‘special’, but successful implementation and the delivery of the targeted emissions savings will pay dividends. More broadly, success with Johan Sverdrup in addition to the smaller fields on the NCS already using power from shore may well see it adopted in other major exploration regions.