The Åsgard oilfield lies on the Haltenbank in the Norwegian Sea, 200km offshore Norway and 50km south of Statoil’s Heidrun field. Statoil is the operator of the field with a 34.57% share. Statoil’s partners are Petoro (35.69%), Eni Norge (14.82%), Total E&P Norge (7.68%) and ExxonMobil (7.24%).

The field comprises the Midgard, Smørbukk and Smørbukk South deposits, which were discovered in 1981, 1984 and 1985, respectively. Water depths are roughly 240-300m. Midgard straddles blocks 6507 / 11 and 6407 / 2, while the other two deposits lie in block 6506 / 11.

Geology and reserves

The Smørbukk deposit is of the Jurassic age and consists of the Garn, Ile, Tofte, Tilje and Are formations. The Smorbukk south deposit is made of the Garn, Ile and Tilje formations. The Midgard deposit is divided into four segments with the primary reservoir consisting of the Garn and Ile formations.

The field has reserves of 830 million barrels of oil and condensate, and 212 billion cubic metres of gas.

Åsgard field development

The Åsgard development consists of a monohull unit (Asgard A), for oil and condensate production with the world’s largest floating gas semi-submersible platform (Åsgard B). The other installations for exploitment of the fields are Åsgard C (a storage ship) and the necessary subsea production installations. These subsea systems are one of the most extensive in world, embracing a total of 52 wells, grouped in 16 seabed templates, linked by 300km of flowlines. Åsgard B was towed out to the field on 14 April 2000, and came onstream in autumn 2000.

In November 2010, the development partners agreed to invest Nkr1bn for the development of the Smørbukk North-East field. Smørbukk North-East was discovered in 2009 and is estimated to contain 15 million barrels of oil equivalent. Recoverable reserves are estimated at 5.7 million barrels of oil equivalent.

Smørbukk North-East has been developed as a tie-back to the Åsgard B platform. Production started in February 2012.

In August 2011, Åsgard partners submitted a plan for the development and operation of subsea gas compression to the Norwegian Ministry for Petroleum and Energy. The subsea compression will improve recovery from the Mikkel and Midgard fields, which are situated 40-50km from Åsgard B, by approximately 278 million barrels of oil equivalent (mboe). Start-up is expected in Q1 2015.

Production

The field produces 1.28bcf per day of natural gas, as well as 163,000 barrels of oil and 94,000 barrels of condensate per day.

Åsgard A oil production vessel

The Åsgard A oil production ship arrived at the field on 8 February 1999. This monohull is permanently moored to the seabed and provides a storage capacity onboard for roughly 907,000 barrels of oil. It can produce up to 200,000 barrels per day.

Oil is transferred, via a loading system, to shuttle tankers for transport to customers or terminals. Oil production began on 19 May 1999.

Åsgard B floating gas production vessel

Åsgard B is a semisubmersible, floating platform with process plants for the treatment of gas and the stabilisation of oil and condensate. Developed by Kvaerner / GVA Consultants in Gothenburg, the semisubmersible platform has been designated a Kvaerner GVA70. The fabrication was carried out under a $1bn turnkey EPIC contract, with Kvaerner.

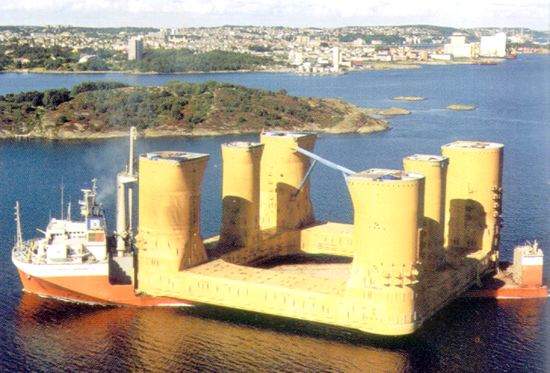

The Åsgard B hull comprises a ring pontoon with six columns to support the topsides. It was built in Korea by Daewoo Heavy Industries, under an $85m contract. The hull measures 114mx96m and weighs 19,000t. The heavy-lift carrier Mighty Servant 3 transported the hull to Norway in a 45-day journey.

Measuring 96mx114m, the platform B topside weighs 28,000t, and incorporates living quarters and processing facilities. It also carries operative deck loads of 15,000t.

Construction of the platform deck began at Kvaerner Rosenberg’s Stavanger yard. The two topside halves weighing a total of 33,000t were welded together, before being mated with the hull. This operation took place in the Amy Fjord in October 2001.

Åsgard C condensate storage tanker

The Åsgard C storage unit was built in Spain’s Sestao yard in Bilbao and arrived at the field in May 2000. Work then commenced pulling in and locking the condensate loading buoy. It was then connected via a flexible riser to the seabed flowline leading to the Åsgard B gas and condensate production floater located 4km away.

Measuring 264m long, the vessel belongs to Knutsen OAS Shipping in Haugesund north of Stavanger and has a storage capacity of 868,000 barrels.

Pipeline

The 707km Åsgard Transport gas trunkline transports gas from the field to the Karsto treatment complex north of Stavanger. This line ties Åsgard and other Norwegian Sea fields to markets in continental Europe and the UK.

An expansion of the facilities at Karsto separates rich gas from Åsgard into lean gas (methane) for onward transmission by pipeline, and ethane, butane, propane and naphtha for export by ship. The Europipe II gas trunkline, runs 650km from Karsto to the receiving facilities at Dornum on the German coast.

Åsgard contracts

FMC Technologies won a $45m contract in July 2008 to supply subsea equipment for the field. The contract included the supply of subsea trees, wellhead systems and flow control modules.

In December 2009, Technip was awarded a contract to install a 4km long flowline between the Åsgard B platform and one of the subsea templates to balance production on the field.

In June 2010, Grenland Group won a contract to replace a swivel stack on the Åsgard A platform.

In December 2010, Aker Solutions was awarded a Nkr3.4bn contract for the design and construction of subsea gas compression unit for the field. The compression unit will include a gas cooler, liquid separator and compressor.

Aker Solutions was again contracted in June 2011 for subsea compression topside modifications on the Åsgard field. The Nkr650m contract will be carried out as an engineering, procurement, construction and installation contract. The work will be completed in Q4 2014.

In February 2012, Technip won a $194m (€150m) contract to install the subsea compression system. Technip will also connect the system to the existing subsea infrastructure and the platform.

Technip was also contracted to undertake deep water testing of remote hot-tap equipment of the pipeline repair system during the same month. The contract also includes associated preparatory works and installation of protection structures.

Bergen Group Rosenberg, a subsidiary of Bergen Group, was contracted in February 2012 to manufacture subsea structures for the compression project.