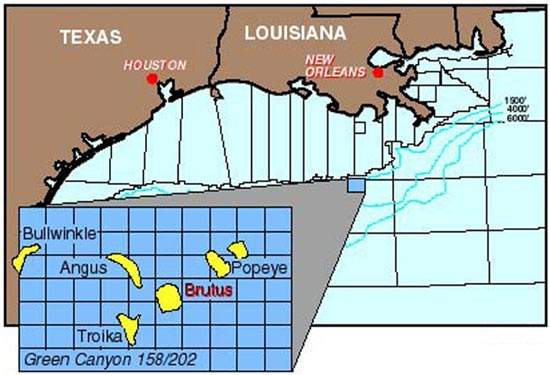

Brutus is located 165 miles south-west of New Orleans, USA. Target reserves are in the Plio-Pleistocene sands at depths of 12,500ft-17,500ft.

Te Brutus discovery well was drilled on Green Canyon Block 158 in December 1988. An appraisal well was drilled on the same block in 1994.

Owner Shell announced plans to develop Brutus in April 1999 using a tension leg platform (TLP) for installation on the same block in 2,985ft of water.

The tension leg platform consists of five modules weighing 11,500t.

The Ocean Worker semi-submersible drilling rig of Diamond Ocean Worker was used for the batch setting of eight wells. Batch setting was completed in January 2000.

Furthermore, six of the planned development wells for the eight-slot TLP were predrilled, with the well layout on the seafloor arranged in a rectangular pattern.

The TLP was installed in mid-2001 using the derrick barge Hermod. Heerema was the contractor for installing the TLP.

The estimated ultimate gross recovery from the Brutus development is greater than 200 million barrels of oil equivalent (boe), with a 70:30 oil to gas ratio.

Average API gravity for the oil is low-mid 30 degrees. Sulphur is at 1.5%.

In February 2002, the Brutus tension leg platform was closed due to valve failures in the production processing system.

Shell used this downtime to increase the production capacity to 130,000 barrels per day (bpd). At that juncture, Brutus was producing 60,000bpd and 90 million cubic feet of natural gas per day from four wells.

Subsea system

The Glider subsea system, comprising two wells, was used for the Brutus project.

It was tied back about seven miles to the project in July 2004 via a 6in buried and insulated flowline, and was the first subsea tieback TLP.

The Glider field’s subsea system is situated at water depth of around 3,400ft.

Brutus design

The TLP facilities are designed to accommodate a peak gross production of approximately 110,000bpd and 150 million cubic feet (Mcf) per day of gas.

The TLP was used as a hub for surrounding developments and it is thus designed to handle an amount of gas greater than that required for the Brutus development, which is about 150mcf per day of gas.

Completely assembled, the TLP is 3,250ft-high, from the seafloor to the crown block of the drilling rig.

Daewoo Heavy Industries had delivered the hull in January 2001. It consisted of four circular steel columns, 66.5ft in diameter and 166ft-high. The 35.5ft-wide and 23ft-high columns were linked with a rectangular section using pontoons.

The weight of hull is around 13,500t, with an aggregate displacement of 54,700t.

The installed deck was 245ft² and approximately 40ft-high. The deck consisted of five modules, namely processing, drilling, power, living quarters and a wellbay.

The deck modules are set in an open-truss frame design with a total structural steel weight of approximately 7,650t.

The total topside weight was approximately 22,000t, including all process equipment and the drilling rig.

Development

J Ray McDermott developed the modules at its Amelia fabrication yard in Los Angeles. The modules were delivered at CSO Gulf Maritime’s integration yard in 2001.

The hull and deck were configured at Aker Gulf Marine’s Ingleside fabrication yard, near Corpus Christi, Texas.

The deck modules were transferred to hull by using specialised lifting device, which was developed for Mars TLP integration.

The TLP supports a contract-drilling rig, equipped with a surface BOP and a high-pressure drilling riser. The quarters module will be able to house up to 94 people.

The TLP is secured by 12 tendons, each 2,900ft-long, three per corner, each with a diameter of 32in and a wall thickness of 1.25in.

The total weight for the 12 tendons is approximately 7,500t.

The TLP foundation system consisted of 12 piles, which were attached to the tendons. The piles were 82in in diameter and 340ft-long, weighing approximately 245t each.

Aker Gulf Marine fabricated the piles and tendons at their Ingleside fabrication yard in Texas.

Production from Brutus

Oil production is piped approximately 26 miles via a 20in-diameter pipeline to the South Timbalier 301 B platform, where it is then connected to the existing Amberjack System.

Gas is being piped 24 miles via a 20in gas pipeline and is connected to the existing Manta Ray Offshore Gathering system in Ship Shoal Block 332.

The production was on track from August 2001.