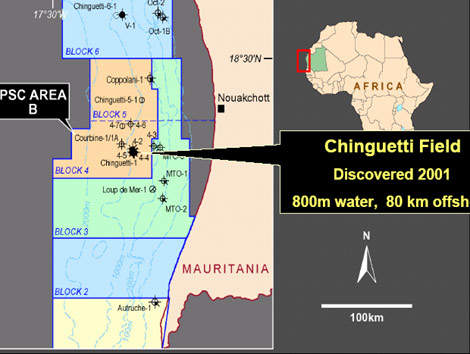

The Chinguetti field lies off the coast of the Islamic Republic of Mauritania, North West Africa, in Block 4, PSC (Production Sharing Contract) area B, about 80km west of the Mauritanian coastline and 90km from the capital, Nouakchott. It is operated by Woodside Mauritania on behalf of AGIP, Hardman Petroleum, Fusion Oil and Gas and Roc Oil. The development works under a PSC with the Mauritanian Government.

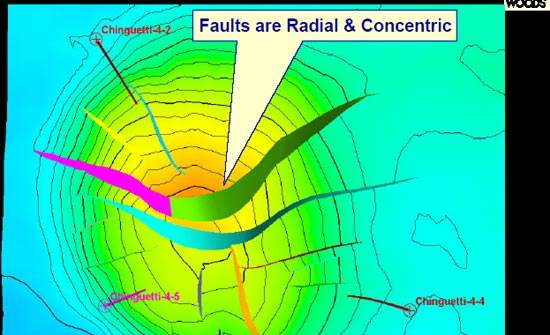

Chinguetti was discovered in 2001. Geologically, Chinguetti is a faulted anticlinal structure with an area of around 12km² and a diameter of 4.5km. It is dominated by a major east-west trending normal fault with a maximum throw in excess of 250m at the crest. The Miocene submarine fan / channel reservoirs are is located 1,300m to 1,900m below the seafloor. The development consists of three main gas discoveries, at Chinguetti, Tiof and Banda.

Estimated recoverable oil reserves were originally put at 120m bbl (19m m³) but in November 2006 Woodside issued a statement cutting the field’s Proven and Probable (2P) reserves to 53m bbl. At the end of 2007, 2P reserves were put at 34m bbl.

The total development cost to first oil is said to be about US$750m.

Drilling

The Chinguetti development has 21 exploration, appraisal and development wells. These include one commitment well in the Dorade prospect in PSC area C2 and five exploration wells in PSC areas A and B. The operator has also drilled up to four appraisal wells on the Tiof discovery.

In addition, the development drilling programme on Chinguetti itself involves up to six oil production wells, four water injection wells and one gas injection well in Phase 1 development.

The drilling has been carried out by two deepwater drilling units – the West Navigator and the Stena Tay. The West Navigator batch-drilled the top hole sections before the Stena Tay started the bottom hole target sections. The West Navigator started with the exploration wells Dorade, Capitaine, Tevet and the Tiof-A appraisal well, before moving on to the Tiof-3 appraisal well on the Tiof discovery.

Phase 1 drilling and completion of development wells finished in September 2005 and installation of production facilities was completed in February 2006.

An infill production well, comprising Phase 2a development, was drilled and completed from December 2006 to March 2007.

In March to April 2007 a high-resolution 4D seismic survey was acquired over the field to assist in planning the Phase 2b infill drilling programme. Phase 2b development is in progress and, to this end, Chinguetti-19 was drilled and completed as a producer in July 2008.

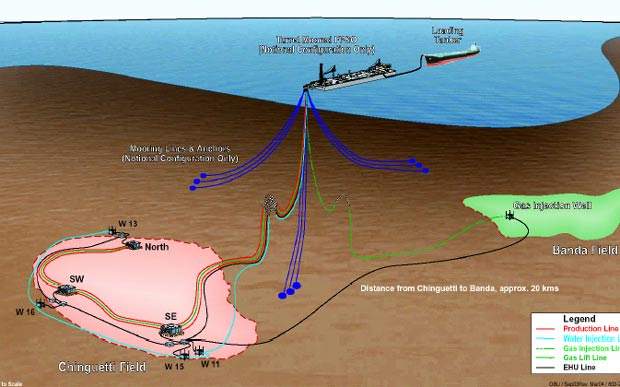

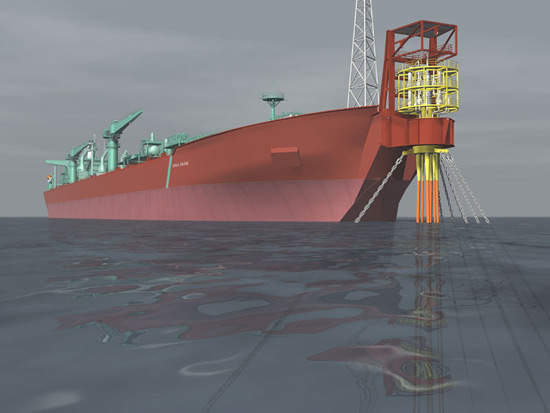

The field has been developed by an FPSO, located approximately 5km from the centre of the field, in a north-east or south-east trending direction. Chinguetti is producing from six wells – five for water injection and one for gas injection – from three drilling centres / manifolds. The production wells are capable of being gas-lifted.

Production began in February 2006, and reached its target rate of 75,000 bopd within two weeks; within three weeks cumulative production had reached a million barrels. The first cargo loading of about a million barrels of crude oil was completed in late March 2006 and was shipped to China.

For the quarter ending 30 June 2008, the average gross production rate was 8,844 bopd. Field life is expected to be in the order of 8 to 15 years.

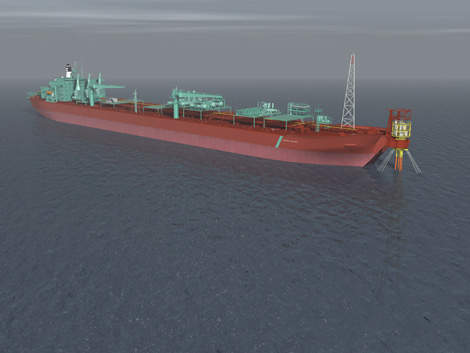

FPSO

Oil enters the FPSO via flexible flowlines and risers. Surplus gas not required for fuel will be returned to a reservoir via a gas injection well located several kilometres outside the field and connected to the manifold by a gas injection line. Produced formation water separated from the oil will be treated and discharged overboard.

Woodside is using the converted trading tanker Berge Helene, which was built as a tanker at Chantiers de L’Atlantique in France and is now owned and operated under a service agreement with Bergesen Offshore, of Norway. It has a 384.75m overall length or 330.77m between perpendiculars, a breadth of 51.87m and a depth of 27.34m. It has a 21.37m draught. It registers 137,578t gross, 103,583t net and has a deadweight of 274,467t. It is designed to withstand the 100yr storm condition of 6.1m waves. The Berge Helene has a storage capacity of up to 1.6 million barrels of oil.

The vessel is powered by two Stal-Laval steam turbines, which total 32,445bhp. These are linked by triple and double-reduction gears to a single screw shaft. The ship has a service speed 16 knots.

In 2001-02, the tanker was converted at the Jurong shipyard in Singapore. The oil and gas processing facilities were provided by ABB Offshore Systems. It has an External Turret Production system (ETP). Bergesen awarded Advanced Production and Loading (APL) the contract for the single point mooring (SPM) system. Berge Helene was re-classified by Det Norske Veritas and approved for use as a permanently moored vessel for oil field production for at least another ten years.