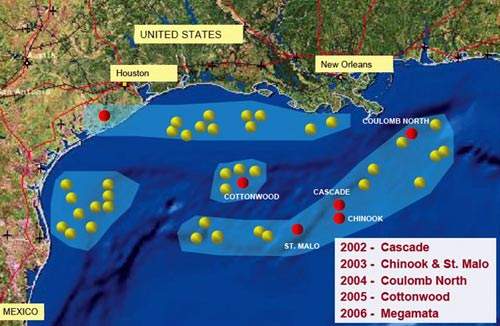

The Cottonwood field is located in the Garden Banks quadrant, block 244, in the US sector of the Gulf of Mexico. The field lies roughly equidistant between Houston and New Orleans, 138 miles off the Texas coast.

Cottonwood is the operator’s first subsea development project in the Gulf of Mexico. It is also the first field in deep waters developed and put into production by Petrobras, as operator, outside of Brazil. The wellstream is primarily gas.

COTTONWOOD DEVELOPMENT

The Cottonwood discovery was drilled in June 2001 by Kerr-McGee as operator, with Petrobras holding a 33.3% working interest. Petrobras acquired 100% interest in the field in December 2004.

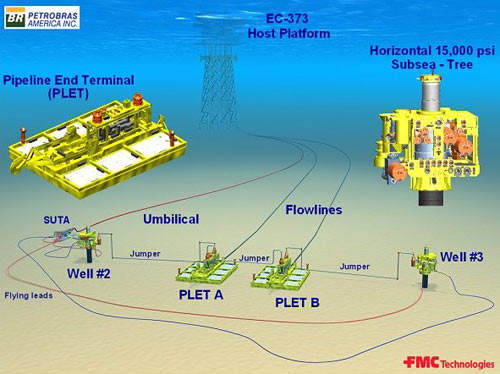

The field development consists of a two-well, long-distance subsea tieback via 27km (17 miles) of 152mm (6in) pipeline to the W&T-operated and Enterprise-owned fixed platform in East Cameron block 373.

The two trees lie in water depths of 670m (2,200ft). Petrobras America selected FMC technologies to supply subsea drilling and production equipment for the project.

A keynote of the field is the high pressures involved. The wellheads, therefore, feature 15,000psi enhanced horizontal subsea trees with a tree bore size of 5in x 2in. FMC also supplied pipeline end terminations and production control system.

PRODUCTION AND PIPELINE

The production is transported 17 miles (27km) via subsea pipelines to the host production platform. Control is by an umbilical consisting of two electrical quads for power and signal operations and 11 super duplex steel tubes for hydraulic power and chemical injection.

The umbilical was manufactured at the Oceaneering Multiflex plant in Panama City, Florida and was installed using the Ocean Intervention II, a dynamically positioned (ABS 2) multiservice vessel.

In 2007, first well was brought online. The gas flow rate is being increased initially to 40 million standard cubic feet a day (1.1 million cubic meters a day).

A second well raised the field production to 70 million standard cubic feet of natural gas a day (2.0 million cubic meters a day), combined with oil condensate production that will take the field production to 20,000 barrels of oil equivalent a day.