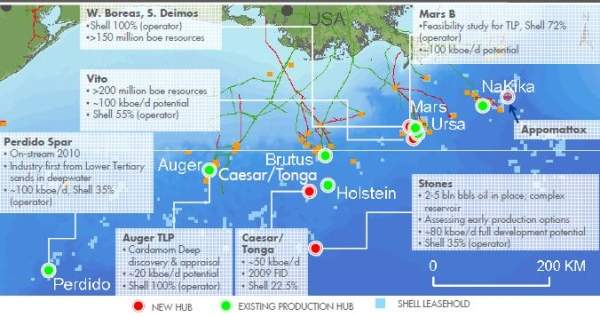

The 3,000ft-deep Deimos offshore field is located in the Mississippi Canyon Blocks 762 and 806, adjacent to the Mars production unit in the Gulf of Mexico.

Shell Exploration and Production Company (SEPCO) is operating the field with a 71.5% working interest, while British Petroleum holds the remaining 28.5% interest in the field.

The field is tied back to the subsea production facilities of Mars, and has been producing since June 2007.

Development of SEPCO and BP’s Deimos offshore field

The Deimos prospect was spud in June 2002 by Transocean’s Deepwater Nautilus semi-submersible. It was discovered in September 2002 when SEPCO encountered with 248 true vertical net feet oil in multiple sands of the exploratory section and 287ft oil in the known producing field pays.

The field was developed in two phases. The objective behind the phased development is to realise short-term production while gathering information on future developments to mature the Deimos prospect in an efficient timeframe.

Phase one operates at a peak capacity of 30,000 barrels of oil a day (bopd). It consists of a three-well subsea system tied back to the existing Mars tension leg platform (TLP), which has been operating since 1996.

Based on the positive results of the phase one appraisal data and production, SEPCO commenced the phase two development in April 2011.

Phase two is integrated with the ongoing development of Mars B project which involved construction of a second TLP, known as Olympus, to support the processing of oil drawn from eight Mississippi Canyon Blocks, including the Deimos deposit.

Mars B was approved for development in September 2010 and became operational in February 2014.

Mars tension leg platform (TLP) details

Stationed in Block 807, the existing 3,250ft-tall Mars TLP weighs approximately 36,500t, and houses a separation, dehydration, treatment facilities; a control room; and an emergency response centre.

Oil from the Mars platform is transported to the Clovelly storage facility in Los Angeles via a 116m-long and 18/24in pipeline. The gas from the platform is carried to West Delta 143 via a 14in pipeline.

Olympus TLP development phase

The phase two development capitalised on the SEPCO’s proven concept of deep water TLPs. The Olympus TLP was designed to process 100,000bopd.

The Olympus TLP was installed at a depth of 3,000ft in Block 807 and is located 95 miles south of New Orleans, Louisiana. The platform has the largest tendons ever built to date, measuring 290ft-long and weighing 170,000lb. Four tendons are placed at each corner of the platform.

The TLP is equipped with marine instrumentation system (MIS), a computer-based system that enables the platform operators to acquire, display and record data relating to the vessel, marine and environment.

The export pipelines of the Olympus TLP are tied to the new upcoming platform C of the existing West Delta 143 hub.

Contractors involved with the Deimos offshore field development

The American Bureau of Shipping (ABS) was appointed as the certification verification agent (CVA). Their scope of work included verification of the Olympus TLP design and fabrication and installation of the hull, topsides, piles and tendons.

Dril-Quip was awarded a $27m contract in October 2010 to supply drilling and production equipment, including the subsea well head equipment, production riser tieback connectors and drilling riser components.

The tendons fabrication contract was awarded in February 2011 to Frank Casing. The contract calls for fabrication of 184 individual tendon segments, as well as the qualification of welding procedures and fatigue testing.

BMT Scientific Marine Services provided the marine instrumentation system (MIS) to install the Olympus TLP.

Cortec supplied both single and double ball valves. The compact ball ranges between 2in and 10in, and the check valves have up to 15,000psi of pressure rating.