The Gajah Baru gas field is situated in Block A in the West Natuna Sea, Indonesia. The field lies at a water depth of 82m.

UK-based Premier Oil is the operator and holds 28.67% interest in the field. Co-owners include Kufpec (33.33%), Amerada Hess (23%) and Petronas (15%).

First gas production started in October 2011 and the field produces 100 million cubic metres of gas a day.

Premier signed three contracts to supply Sembcorp, Pelayanan Listrik Nasional and Universal Batam Energy with gas produced at the field.

Discovery

The field was discovered in 2000 through the Gajah Baru-1 exploration well. The well was drilled by the Trident 17 jack-up rig to a depth of 1,612m (5,290ft).

In 2004, an appraisal well, Gajah Baru-2, was drilled to a depth of 2,746m. The well established the presence of hydrocarbon reserves.

Geology and reserves

The field is estimated to contain 325 billion cubic feet of gas reserves, found in the Miocene reservoirs of the Arang formation and the Oligocene sands of the Gabus formation.

Field development

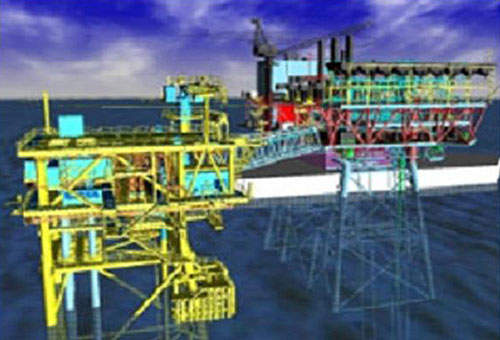

The field was developed by using a central processing platform and a wellhead platform. The two facilities are connected by a bridge.

Premier plans to drill between 12 and 14 exploration and appraisal wells at the field by 2012.

The West Callisto drill rig is being used to carry out the drilling activities.

Platforms

The wellhead platform was installed at the field in September 2010, while the central processing platform was installed in July 2011.

The central processing platform weighs 12,900t. It features gas compression, separation and processing facilities, refrigeration and utilities. It accommodates 60 people.

Pipeline

Produced gas is transported onshore to the Sembgas facility in Singapore by a 3km-long, 16in-diameter export pipeline.

It was installed at a depth of 80m. The installation and commissioning were carried out in 2011.

Contracts

In May 2009, a consortium consisting of Saipem and SMOE Indonesia was awarded a $430m contract for the construction and installation of field infrastructure. The contract includes the construction and installation of the central processing platform, wellhead platform, connecting bridge and gas pipeline.

SMOE was responsible for the construction and installation of the topsides of the central processing platform, accommodation facilities, flare boom and bridge. All the facilities were installed by October 2011.

Nippon Steel Batam was responsible for the construction of the wellhead deck, piles and conductors. It is also responsible for the installation of the central processing platform’s jacket and piles.

Premier contracted Process Group to supply a monoethylene glycol regeneration unit for the central processing platform in August 2009.

Process Group also won the contract to supply a produced water treatment unit for the platform, which is used to separate oil from the produced water. It can treat 2,400 barrels of produced water per day.

In February 2010, Hutchinson Offshore was awarded a contract for providing Leg Mating and Deck Support facilities for the field.

WorleyParsons was involved in the front-end engineering and design stage of the project. The contract for modifying the onshore facilities was awarded to Punj Lloyd.