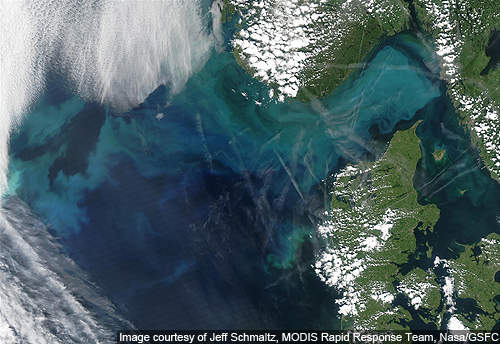

The Gudrun oil and gas field lies in production licence 025 of the North Sea at a water depth of 361ft. The field was discovered in 1974 and is estimated to contain 70 million barrels of oil and 1.7 trillion cubic feet of gas.

StatoilHydro is the operator of the field with a 46.8% stake. Other partners include Marathon Norge with 28.2% interest and GDF SUEZ E&P Norge with a stake of 25%. The partners invested $2bn in the development of the field.

The plan for development and operation (PDO) of the Gudrun field was sanctioned in June 2010. The PDO was submitted to the Norwegian Government in February 2010. First production was achieved in April 2014. The Gudrun oil platform was officially inaugurated in August 2014.

Gudrun platform

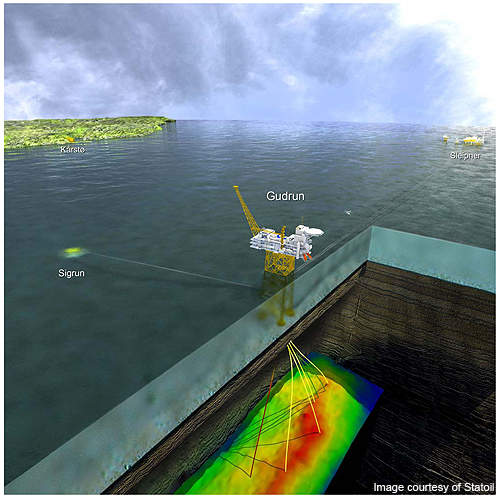

Statoil developed Gudrun using a fixed processing platform supported by a 7,400t steel jacket. The platform was installed at a water depth of 357ft and has 16 well slots. Statoil initially drilled seven production wells. The remaining well slots of the platform may be used during future drilling activities to increase Gudrun’s output.

The platform is tied back to the existing facilities at Statoil-operated Sleipner field located 55km south of Gudrun.

It is also connected to the Kårstø processing plant situated 30km north of Stavanger. The platform receives power via a cable from the Sleipner field.

The platform is equipped with facilities to handle production from the Sigrun subsea satellite development.

Geology

The reservoirs of the Gudrun field are of the Jurassic era and lie at a depth between 4,000m and 4,760m. Oil is deposited in reservoirs in the upper Jurassic Draupne formation. Gas is deposited in the middle Jurassic Hugin formation. Pressure of the reservoir is high at approximately 820bar.

Processing systems

The topsides of the platform have a processing facility for partial processing of the oil and gas produced from the field. The oil and gas is then sent to the Sleipner A platform and Kårstø processing plant where they are further treated.

Oil is stabilised at the Sleipner A platform and sent to the Kårstø processing plant. Water and salts are removed from the oil at the Kårstø plant.

Gas produced at the field is sent to the Sleipner T platform from Sleipner A. At Sleipner T, carbon dioxide is removed from the gas. The gas is then sent back to Sleipner A from where it is exported to Europe through the Gassled system.

Contracts

Aker Solutions was awarded a $77m contract in February 2010 for constructing the jacket for the platform. Delivery and installation of the platform was completed in mid-2011. Aker carried out the engineering, fabrication and load-out of the jacket. The company was also responsible for sea-fastening of the jacket.

Aker was awarded another $144m contract in July 2010 to carry out modifications to the existing facilities in the Sleipner area for tie-back of the Gudrun platform. The company was responsible for engineering, procurement and installation of the equipment required for modification.

In June 2010, Statoil awarded Aibel a $430m contract to engineer and construct the topside facilities for the Gudrun platform. The platform deck was constructed at Haugesund in Norway.

Aibel was also awarded the $9.3m front-end engineering design (FEED) contract in March 2009. The company carried out FEED studies for the topside facilities, living quarters and jacket interface.

Saipem was awarded a contract for transport and installation of the platform jacket and topside facilities in June 2010. The company used its S7000 semi-submersible crane vessel to carry out the installation works.

Arvid Nilsson received a contract from Statoil to provide bolts to the oil platform, in June 2013.