The Jangkrik Complex Development comprises two gas fields, namely the Jangkrik and Jangkrik North-East fields.

The gas fields are located within the Muara Bakau block of the Kutei basin approximately 70km off the coast of Makassar Strait, Indonesia, at water depths between 200m and 500m.

Eni holds a 55% share in the development and operates the Muara Bakau permit, while ENGIE E&P holds 33.3% through its subsidiary GDF SUEZ Exploration Indonesia BV and PT. Saka Energi Muara Bakau holds a 11.66% working interest in the permit.

Development of the two gas fields is expected to cost more than $4.13bn.

The plan for development (POD) of Jankrik was approved in November 2011 and the POD for Jangkrik North-East was subsequently approved in January 2013.

First production was achieved in May 2017 and is expected to reach 450 million metric cubic feet of gas a day (mmscf/d) for the first six years before continuing to produce at a lower capacity for approximately eight more years.

Up to 47% of the gas produced from the Indonesian offshore field is intended for domestic supply, while the remaining gas will be exported to neighbouring Asian countries.

Exploration, discovery, geology and reserves

Eni discovered first gas at Jangkrik in April 2009 by drilling the exploration well at a water depth of 400m.

The Jangkrik-2 appraisal well, drilled to a total depth of 2,449m at water depth of 425m, was successfully appraised in June 2010.

Jangkrik-2 produced gas at a rate of 17.5mmscf/d during the production test. Another well was drilled in December 2010, at a water depth of 416m and total depth of 2,849m, to confirm the discovery of Jangkrik.

Jangkrik North-East was discovered in July 2011 by drilling an exploration well at a water depth of 460m and total depth of 3,633m.

The well produced gas at a rate of 30.6mmscf/d during the production test. The reservoir at Jangkrik is located within the sands of the pliocene age, while the reservoir at Jankrik North-East is located within the sands of the pliocene and miocene age.

The gas fields hold combined proven reserves of more than 1.3 trillion cubic feet.

Development of the Jangkrik Complex

Development of the deepwater Jangkrik Complex primarily involved workovers on some existing wells, the drilling of new production wells and installation of a new barge floating production unit (FPU) with a treatment capacity of 450mmscf/d of gas and condensates.

Construction of the FPU was completed in March 2017.

The FPU is tied back to the East Kalimantan pipeline, which further conveys the produced gas to PT Badak’s Bontang LNG plant where the gas will be liquefied, and the condensates will be conveyed to Senipah Terminal.

The Jangkrik FPU is expected to become a hub for the development of nearby gas discovery Merakes, which is slated to begin production within the next two years.

Contractors involved with the project

A $1.1bn engineering, procurement, construction and installation (EPCI) contract for the FPU was awarded to a consortium comprising Hyundai Heavy Industries (HHI), Saipem, Tripatra Engineers & Constructors, and Chiyoda.

The topsides were fabricated at Saipem’s Karimun Island Yard and the hull was fabricated at HHI’s Ulsan yard in South Korea.

A $720m contract for the supply of the subsea systems, including subsea trees, manifolds, jumpers and connection systems, umbilicals, tooling and ancillary topside, and subsea controls systems, was awarded to FMC Technologies in February 2014.

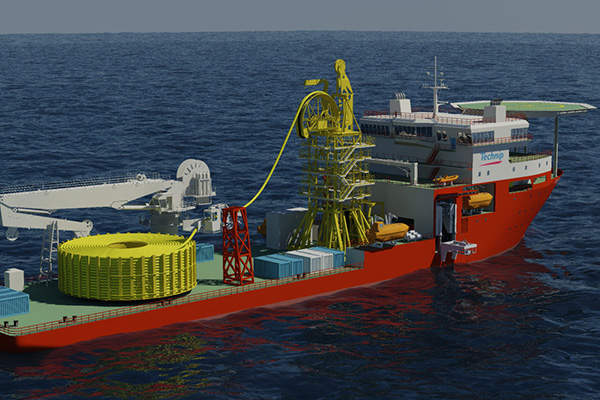

Technip was awarded an EPCI contract for 36km of flexible risers and flow lines with diameters ranging between 4in and 14in, as well as 195km of pipeline with diameters between 4in and 24in.

The company also provided subsea equipment such as midwater arch and flow line end termination (FLET) systems.

Its offshore vessels G1201 and Deep Orient will carry out the installation works.

In addition, Technip was responsible for installing 51km of umbilicals, five manifolds, seven subsea isolation valves (SSIV), subsea structures and associated flying lead connectors.

The company was also awarded the EPC contract for the onshore receiving facility, which features equipment such as pig traps, metering systems and utilities.