The Juniper offshore project, located in the East Mayaro Block (Block EM) off Trinidad and Tobago’s south-east coast, comprises the development of the Corallita and Lantana gas fields owned by BP Trinidad and Tobago (bpTT).

The two fields are located 50mi (80.4km) off the south-east coast of Trinidad and Tobago, in water depths between 330ft and 360ft.

The project was sanctioned in August 2014 and the fabrication of the gas gathering platform began in the same year. Offshore drilling is expected to begin in May 2015 and first gas is expected in 2017.

Discovery and reserves

The total reserves of the Juniper project are estimated to be 1Tcf. The Corallita and Lantana gas fields, discovered in 1996, are part of the prolific Columbus basin.

Juniper offshore project development and infrastructure details

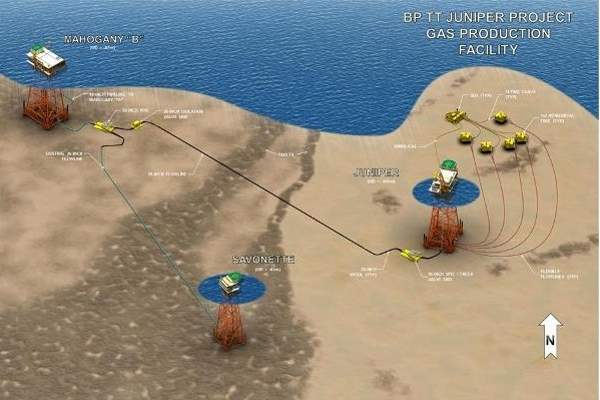

The development of the Juniper offshore gas project will include the drilling of five subsea wells (three in Corallita and two in Lantana), which will be tied in to a new normally unmanned platform that will gather gas from the two fields.

The subsea production system will consist of five multiphase flexible flow lines, an umbilical line from the platform location to the subsea distribution unit, flying leads, and control equipment. The subsea production capacity will be 590 million metric standard cubic feet a day (MMscfd) of natural gas and 2,500 barrels a day of condensate.

Drilling is scheduled to begin in May 2015 by Ocean Victory, a semi-submersible drilling rig that is capable of drilling to a maximum depth of 25,000ft in water depths of up to 6,000ft.

Processing

The gas gathered on the Juniper platform will be transferred to the Mahogany B hub, through a newly constructed 10km-long flow line, for processing. The offshore connection will be established via a subsea piggable wye tie-in near the base of the Mahogany B platform. Brownfield modifications will be made to the Mahogany B platform to enable the processing.

The processed gas and fluids will be transported to bpTT’s Galeota Point Terminal respectively through two existing pipelines, a 40in-diameter gas pipeline and a 12in-diameter liquids pipeline.

Juniper offshore platform

The normally unmanned platform at Juniper will include a 4,300t topside and a 6,100t jacket. It is being fabricated at LABIDCO Industrial Estate in Trinidad, while offshore installation is scheduled to begin in the second half of 2016.

A front-end engineering and design (FEED) study for the mooring and foundation of the platform was initiated in 2011, following which the mooring solution engineering started. The offshore installation was completed in November 2014, marking the biggest foundation installation campaign offshore Trinidad and Tobago.

The mooring process was carried out in 330ft-deep water amid strong currents.

Contractors involved with the development of the Juniper offshore project

Technip USA was awarded the engineering, procurement and construction (EPC) contract of the jacket and topsides of the platform. It will also be responsible for the fabrication, transport, installation and pre-commissioning of the flow lines, subsea pipeline, subsea structures and tie-in spools.

Diamond Offshore Drilling supplied the semi-submersible drilling rig Ocean Victory for an initial period of two years.

The platform mooring and foundation installation was carried out by Acteon company InterMoor, which designed and fabricated eight piles, which are 128ft-long and 4ft in diameter, and installed them using its Boa Deep C vessel using H-links. A hydraulic hammer required during the installation of the platform foundations was provided by MENCK.