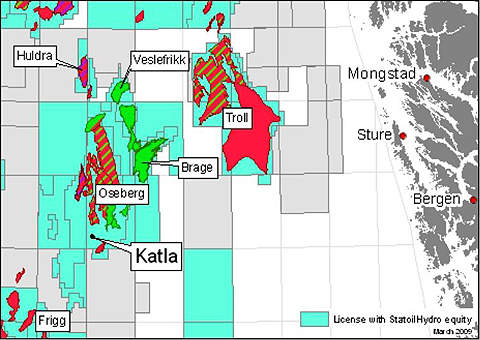

The Katla oil and gas field lies in production licence 104 of the North Sea, Norway. The field is located 11km from the Oseberg South field at a water depth of 950ft (290m).

Statoil is the operator of the field and holds a 49.3% interest. Petoro (33.6%), Total (10%), ExxonMobil (4.7%) and ConocoPhillips (2.4%) are the partners.

Statoil has put the field on a fast track development schedule. In May 2011, it submitted the field development plan to the Norwegian Ministry of Petroleum and Energy.

The five partners are expected to invest Nkr5.4bn ($1bn) in the development. First production is expected in the first quarter of 2013. Katla is one of four fields put on fast track development, the other three being Vigdis Nordost, Gygrid and Pan / Pandora.

The development strategy is part of Statoil’s aim of maintaining hydrocarbon production levels from the Norwegian Continental Shelf (NCS) at the existing rate. Placing the fields on a fast track schedule will help to reduce the time from discovery to production by 50%. It will also increase the production life of installations in the NCS.

Katla discovery

The Katla field was discovered in March 2009 by the 30 / 9-22 exploration well. The well was drilled to a depth of 3,231m by the Polar Pioneer rig.

Geology and reserves

The majority of Katla’s hydrocarbon reserves were discovered in the Tarbert formation of the upper Brent Group. Gas was also discovered in the Heather formation of the upper Jurassic reservoir.

The field is estimated to contain 40 million barrels of oil equivalent, of which 60% is oil.

Field development

The development plan for the Katla field includes one subsea template and four wells. Two of the wells will be used for the production of oil and gas. The other two wells will be used for water injection to increase the pressure in the reservoir.

The produced oil will be transported to the Oseberg South platform for processing. The gas produced will be transported to the Oseberg Omega North field to maintain reservoir pressure.

Contracts for the Katla field

In September 2010, Statoil awarded a Nkr445m ($75m) engineering, procurement and construction contract to FMC Technologies to supply four subsea production trees and one integrated template structure. The scope of supply also includes a manifold, four wellheads, and related subsea control units and systems. Delivery of the equipment is expected to begin in the third quarter of 2011.

In November 2010, FMC subcontracted Grenland Group to supply the integrated template structure and the subsea manifold. The two modules will weigh more than 386t. Deliveries under the Nkr40m ($6.8m) subcontract are expected to begin in the third quarter of 2011.

Subsea 7 was awarded a contract in November 2010 to install pipelines and control cables for the field. The scope of work includes design, manufacture, installation and commissioning of two 13km-long pipelines and one 13km-long umbilical between the integrated template structure and the Oseberg South platform. Installation of the pipelines and cables is expected to commence in the first half of 2012.

ClampOn was subcontracted by FMC in January 2011 to provide subsea sand monitors for the field.

In February 2011, Malm Orstad delivered four levelling cylinders capable of lifting 150t to FMC. The cylinders will be used to install the integrated template structure at the field. Malm Orstad also delivered a remotely operated vehicle (ROV) panel for adjusting the cylinders at the time of installation of the integrated template structure.

Fabricom was awarded an Nkr140m ($25.4m) contract in May 2011 to carry out modification works on the topsides of the Oseberg South platform. The scope of work includes the installation of a new production flowline and a water injection flowline. New risers, umbilical and necessary control systems will also be installed. The modifications will be carried out over a period of 18 months.