The Kristin field is located in the south-west part of the Halten Bank in the Norwegian Sea.

It straddles block 6406 / 2 (production licence 199 was awarded in 1993) and block 6506 / 11 (PL 134B was awarded in 2000).

Kristin is a gas and condensate field that came online on 3 November 2005 and features 12 production wells.

It currently produces ten million cubic metres of gas a day as of June 2008.

The field is located at a water depth of 370m and its reservoir is situated approximately 5,000m below ground.

Equity

The partners of the Kristin deepwater project include Statoil (55.2%), Petoro (19.5%), Mobil Development Norway (10.8%), Eni Norge (8.2%) and Total E&P Norge (6%).

Kristin was discovered in 1997 and lies roughly 20km south-west of Åsgard’s Smørbukk field.

It is possible that Kristin could form the centre of other nearby discoveries such as Ragnfrid, Lavrans and Erlend.

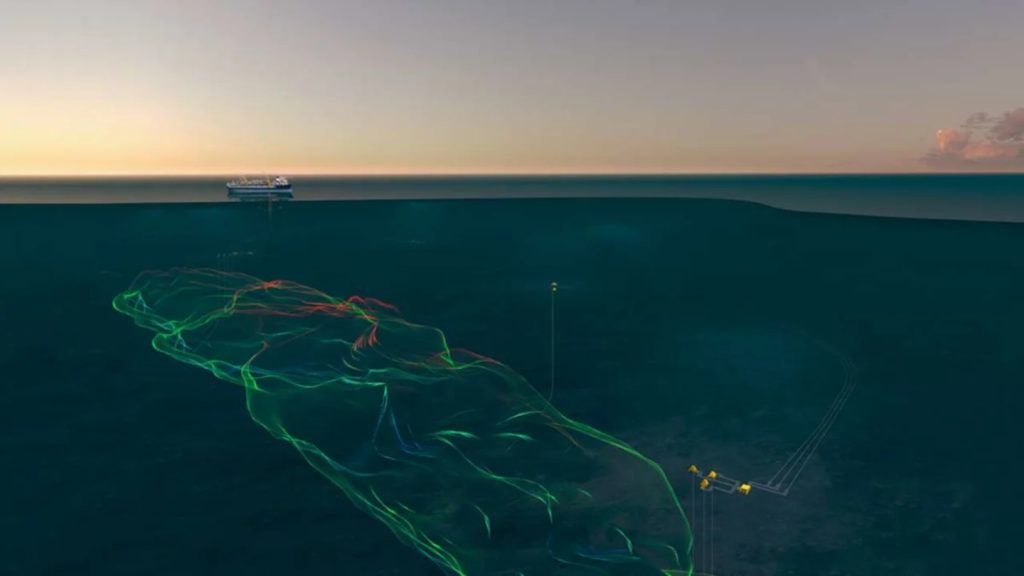

Kristin field development

Kristin was developed by Statoil with an investment of $1.9bn, which was approved in 2002 by the Norwegian Government.

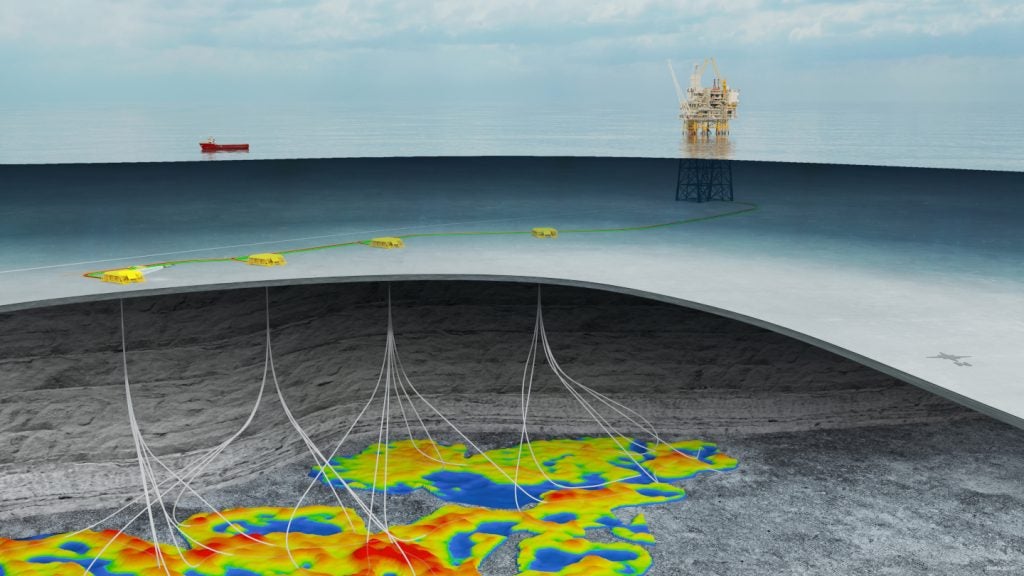

A total of 12 production wells were developed in the field by four subsea templates.

The subsea templates measure 28m x 16m x 13m and were fabricated by Aker Solutions and installed by Saipem 700.

The templates weigh 200t each. They are tied to the production platform and held by four suction piles.

Baker Oil Tools provided completion equipment for the subsea development.

Six flowlines, each measuring 24 miles, were installed by Coflexip Stena Offshore.

These connect the platform with the subsea templates. The flowline equipment was provided by Nexans and Marubeni-Itochu Steel.

Kristin’s gas reserves

The Kristin field has reserves of 35.4 billion standard cubic metres of gas, 8.5 million tonnes (Mt) of natural gas liquids (NGL) and 40.4 million standard cubic metres of condensate. The reservoir lies almost 5,000m beneath the seabed.

The pressure and temperature in this reservoir, at 900bar and 170°C respectively, are higher than in any field developed off the Norwegian shore to date.

Kristin will be developed via 12 subsea production wells.

Producion platform

Kristin field’s production platform is equipped with the required processing facilities for gas and condensate. It was constructed by Aker Stord.

The hull was designed by Aker Solutions and GVA, while its construction was carried out by Samsung Heavy Industries.

The platform risers were installed by Technip Offshore Norge.

Exporting gas from Kristin

Gas recovered from the field is first partially processed at the platform itself and then transported via the Åsgard Transport pipeline to the Karsto treatment complex.

The gas is further processed at the complex and subsequently exported to Europe.

A 19-mile gas export loop is installed from the platform to the Aring;sgard Transport gas trunk line.

The Åsgard A oil production ship takes care of the processing and transportation of the condensate.

Development scheme of choice

The preferred development scheme consists of using a floating production facility with a daily production capacity of 125,000 barrels of condensate and 18 million cubic metres of gas.

In this scenario, the rich gas can be piped through Åsgard Transport to a land terminal (Kollsnes / Kårstø) for the separation of the NGL.

The condensate fraction could then be piped to the Åsgard C storage ship and from there loaded into shuttle tankers with Åsgard condensate.

Statoil has used the Transocean Arctic to drill 5km west of Kristin to prove gas and condensate in the northern part of the Erlend structure.

A minor gas find was previously made in the south.

Statoil also drilled in the M-prospect, 12km north of Kristin using the Scarabeo 5 rig.

Targeted at a separate structure in the 134 B licence, it aimed to check whether gas and condensate were present.