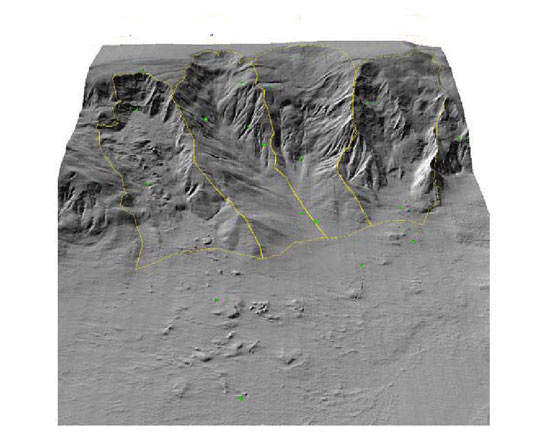

The Mardi Gras system lies in the Mississippi Canyon and Green Canyon areas of the Gulf of Mexico. In the southern Green Canyon area, pipelines are planned to transport gas and oil from the Mad Dog, Holstein and Atlantis fields while in the Mississippi Canyon area pipelines are scheduled to transport gas and oil from the Thunder Horse field.

The BP-operated Mardi Gras is planned to cover 725km (450 miles) from its total of five individual pipelines. On completion, it will be the largest capacity deepwater pipeline system ever built, with the capability of transporting over 1 million b/d and 1.5bcf/d (billion cubic feet of gas per day) from identified and future discoveries. The lines will be laid in water depths of 4,300ft to 7,200ft (1,200m to 1,950m).

LARGE SUBSEA PIPELINES

Large pipeline diameters are required to achieve the production throughput volumes. The scope of trunklines and laterals to develop these fields is complex, with pipeline diameters including 16in, 20in, 24in and 28in. However, the pipelines are designed with constant outside diameters – except for the jumpers and wye-sleds – in order to reduce the cost of pipe manufacture, for ease of installation and to standardise subsea repair equipment.

For the large subsea pipelines, some 120,000t of steel are planned for the southern Green Canyon Area while another 70,000t of steel are planned for the Mississippi Canyon Area.

The pipeline systems consist of:

CAESAR OIL PIPELINE SYSTEM

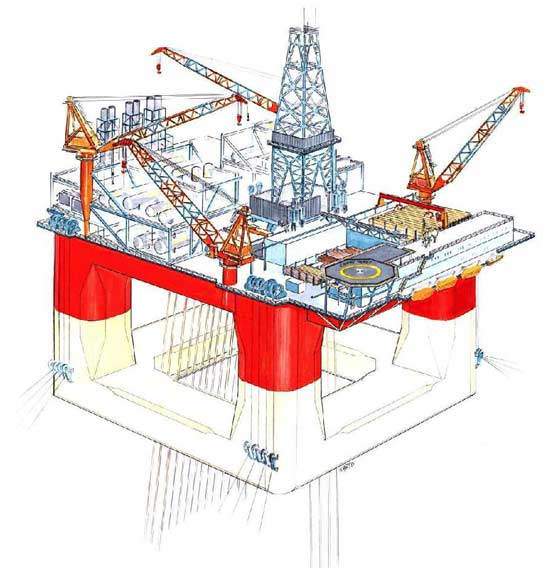

The Caesar Oil Pipeline System in the southern Green Canyon Area includes a trunkline from the Holstein spar to a shallow-water platform at Ship Shoal Block 332 in 430ft of water. A lateral pipeline from the Mad Dog spar ties into the Caesar pipeline and another lateral pipeline from the Atlantis semi-submersible facility ties into the Mad Dog lateral.

CLEOPATRA GAS GATHERING SYSTEM

The Cleopatra Gas Gathering System, also in the southern Green Canyon Area, is similar in configuration to the Caesar Oil line, consisting of a trunkline from the Holstein spar to the Ship Shoal facility, with laterals from Mad Dog and Atlantis tying in.

PROTEUS OIL PIPELINE SYSTEM

In the Mississippi Canyon Area, the Proteus Oil Pipeline System begins with a catenary riser at Thunder Horse and transitions to a larger diameter trunkline to a new-build shallow-water platform at South Pass Block 89E in 400ft of water.

OKEANOS GAS GATHERING SYSTEM

Also in Mississippi Canyon, the Okeanos Gas Gathering System consists of a lateral from Thunder Horse plus the main trunkline, which starts at NaKika and terminates at the Destin shallow-water platform on Main Pass Block 260.

PIPELINE ENGINEERING AND INSTALLATION

BP awarded a contract to Intec Engineering to perform the preliminary engineering services and detailed design. The scope of work included the design of the associated subsea equipment deepwater pipelines and steel catenary risers (SCRs) – two for each of the four deepwater floating host platforms for a total of eight gas and oil units.

Risers measuring 16in to 24in in diameter will be suspended from the platforms using flex joints. Strakes, spiralling down each riser, are then planned to substantially reduce the SCR vibration to manage fatigue.

Bredero in Alabama was responsible for fusion-bonded epoxy (FBE) coating the line pipe for corrosion prevention.

Heerema will use the Balder for installing the pipe using standard 40ft joints that are welded into hex-joints for J-lay. In 2004, Heerema will begin installation of the SCRs, following installation of the first hulls.

Allseas’ pipelay vessel Solitaire began pipelay in intermediate water depths in November 2002 using the S-lay method. This work terminates at each of the shallow-water fixed platforms.

The sleds and pipeline end terminals (PLETs) were carried out by Omega in Louisiana. Equipment on the sleds, including line pipe, valves, collet connectors and piggable wyes, were delivered in 2002 and early 2003. Twenty sleds, some weighing as much as 110t and measuring approximately 60ft by 20ft, are planned, with asymmetrical vertical wyes selected for the subsea tie-ins to allow bi-directional pigging of the main pipeline during commissioning. Multi-diameter wyes planned for the tie-ins also will accommodate the varying sizes of the pipelines.