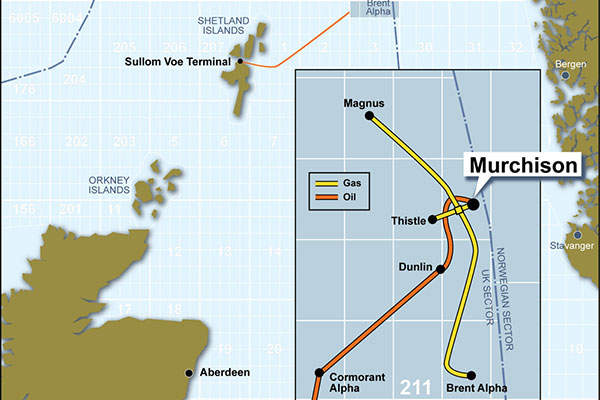

The Murchison field is located in the Northern North Sea in East Shetland Basin in the UK Continental Shelf (UKCS). The field is situated to the north of Aberdeen and spans the UK/Norwegian sector median line. It lies in the UK Block 211/19 and extends into the Norwegian Block 33/9.

CNRI initiated plans to decommission the field in 2009 that involved surveys, data collection and extensive studies. Cessation of production application was submitted to the UK Department of Energy and Climate Change (DECC) in 2011 and the same was approved in 2012.

The project includes decommissioning of the offshore platform and the associated subsea pipeline and production well infrastructure.

The decommissioning began in the fourth quarter of 2013 and is expected to continue for approximately five years. Plugging and abandoning the 33 platform wells that have subsea tie-backs to three remote wells began in late 2013. The field, meanwhile, permanently stopped producing in March 2014.

Murchison offshore field discovery and production

Discovered by Conoco Philips UK in 1975, the field produced its first oil in 1980. CNR International (CNRI) became the operator in 2002 with Wintershall as its partner. The field produced peak oil of 150,383 barrels per day (bpd) in December 1982, whereas the total oil produced during its production phase stood at 400 million barrels.

Murchison oil field infrastructure

The Murchison platform was installed in 1979 and became part of an intricate framework exporting oil onshore to Sullom Voe through a pipeline. Import and export of gas were carried out through the Far North Liquids and Gas System (FLAGS) line.

Lying in 156m of water, the platform is supported by an eight-legged steel jacket and has topside modules for drilling, production & accommodation (263 beds).

Murchison is one of the biggest steel jacket platforms in the North Sea, with its topside weighing 24,500t and consisting of 26 modules that can be easily dismantled and transported onshore.

Murchison field decommissioning details

In agreement with the Oil & Gas UK’s directions, the platform and subsea wells will be plugged and abandoned. The topside modules will be dismantled and brought onshore to be reused, recycled or disposed of.

The jacket footings will remain in place although the jacket will be removed to a height of approximately 44m above the sea bed and brought onshore for reuse, recycling or disposal purposes.

The drill cutting piles will be left in their original location, the jacket footings, to decay naturally over a period of time.

A seabed survey will be conducted on the completion of the decommissioning programme to ascertain any oil field-related debris. The survey area will cover a 500m zone within the platform and a 200m-wide corridor along each pipeline. It will be followed by a categorisation of the debris and establishing a recovery plan.

Production pipelines and related subsea equipment will be detached and transported onshore for either recycling or disposal. The principal oil export line will be left in place on the surface, while the uncovered segments will be covered by rocks.

The gas export/import pipeline, a part of the Northern Leg Gas Pipeline (NLGP) system, will not be a part of the Murchison decommissioning programme as it is owned by the NLGP associates.

Contractors involved with the decommissioning

CNR International awarded a three-year contract to Aker Solutions in 2013 for the first phase of the Murchison decommissioning. Aker Solutions will provide engineering design, procurement services and offshore execution, to ensure sage removal of facilities.

Scottish industrial services contractor Bilfinger Salamis UK was subcontracted by Aker Solutions in 2014 for the supply of the fabric maintenance services support and access solutions for the first stage of the decommissioning. The company will provide alternative system scaffold, multi-discipline rope access teams and fabric maintenance services over three years.

Heerema-AF Consortium comprising Heerema Marine Contractors Nederland SE and AF Decom Offshore UK has been contracted for the removal and disposal of the North Sea installation.

The contractual scope includes engineering, preparation, removal and disposal (EPRD) of both the topsides and the jacket structure weighing approximately 37,000t. Engineering work under the contract began in 2014, while the offshore work is scheduled to begin in 2016. The removal and disposal work is expected to continue until 2020.