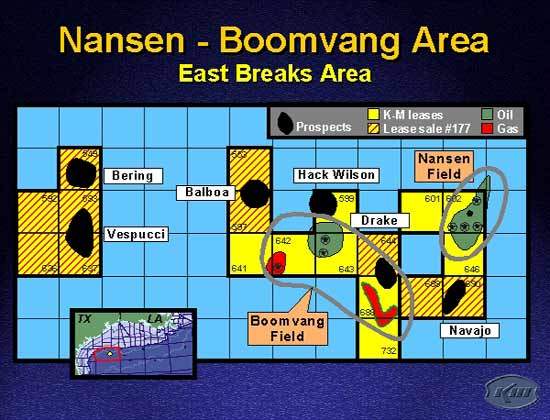

The Nansen and Boomvang fields are located in the East Breaks area of the Gulf of Mexico, approximately 150 miles south of Houston, Texas, US.

Nansen lies in East Breaks block 602 in 3,678ft of water while Boomvang lies in blocks 642, 643 and 683 in 3,453ft of water.

Kerr McGee, now part of Anadarko, operates the Boomvang field with a 30% working interest and the Nansen field with a 50% working interest.

The other partners in Boomvang are Shell (formerly known as Enterprise, 50%) and Ocean Energy (20%). Ocean Energy holds the remaining 50% interest in the Nansen field.

Nansen and Boomvang drilling

Nansen was discovered in October 1999 in 3,680ft of water approximately eight miles east of the previously announced North Boomvang discovery.

Successful drilling of Nansen No 8 well on East Breaks 602 extended the field to the south.

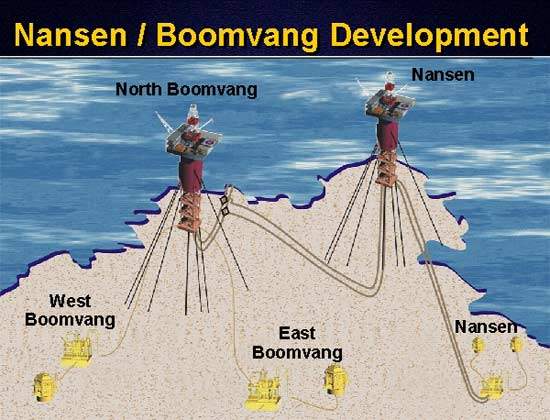

A second rig was secured at Boomvang to concurrently drill a total of up to seven wells at North and East Boomvang in the Gulf of Mexico.

Sub-sea well development

Nansen achieved the first production from the first of three subsea wells in early 2002.

Daily production from the Nansen field was ramped up to a peak rate of about 40,000 barrels of oil and 80 million cubic feet of gas by the fourth quarter of 2002, as completion activities at the remaining nine dry tree wells were completed.

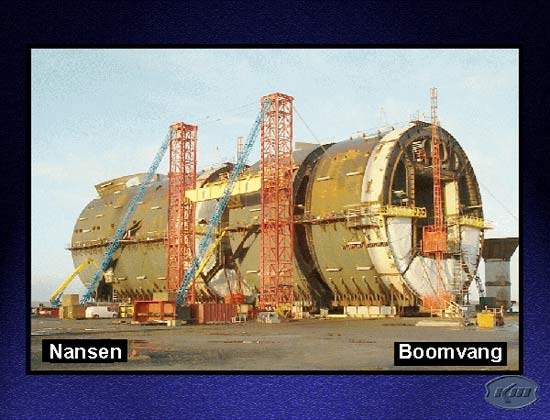

Both Nansen and Boomvang were developed with the world’s first truss spars.

The truss design replaces the lower cylindrical hull in order to reduce weight and cost.

The open truss structure also reduces movement and three heavy plates enhance stability. The Spars are 543ft in length and weigh 17,000t each.

Air chambers in the upper hull provide buoyancy for the floating structures.

Each spar has a production capacity of 40,000 barrels per day (bpd) and 200 million cubic feet per day of gas.

The wells were completed beneath the spar and tied back through top-tensioned risers to dry wellheads and trees.

Additional tie-ins are incorporated from sub-sea satellite wells. In total, there are nine top-tensioned production risers and associated equipment for Nansen and five for Boomvang.

Gas export from Nansen and Boomvang

Williams constructed and operates the Seahawk Gathering System, which moves all gas produced from Nansen and Boomvang.

The Seahawk construction project includes a 65.98km of 18in-diameter line, connecting the spar platforms to a new shallow-water facility on the shelf in GAA-244.

From there, an 88.51km-long, 24in-diameter pipeline was laid to export the gas to interconnection on Williams’ Central Texas Gathering System in BA538.

Boomvang and Nansen Joint Oil (BANJO) system

Williams constructed and operates the Boomvang and Nansen Joint Oil (BANJO) System to move all the oil.

BANJO is a 16in-diameter, 65.98km-long oil-export pipeline that extends from the Spar platforms to the shallow-water facility in GAA-244.

From there, it interconnects with ExxonMobil’s Hoover Offshore Oil Pipeline System.

Both the Seahawk and BANJO Systems include deepwater sub-sea junction facilities for gathering oil and gas from future deepwater.

Pipeline

The main pipeline was subcontracted by Williams to Coflexip Stena. The company used its CSO Deep Blue new build.

Wellstream designed and supplied the 5.625in, 6,000psi flexible pipe production risers and tie-in jumpers for the project.

The risers were installed in a catenary configuration, enabling the spars to be offset for future on-site drilling.

Contractors involved

Spars International was contracted to design the almost identical truss spar systems. Bridon supplied HDPE sheathing on the wire spiral strand to be used for the spar moorings.

Cal Dive International installed infield flowlines using its reeled pipelay system deployed from the Sea Sorceress. The contractual scope included the installation of approximately 100,000ft of 6in-diameter pipelines, five flexible production risers and 86,000ft of associated umbilicals, as well as the jumpers and flying leads necessary to tie in three sub-sea trees.

RCI Energy Group was engaged in the engineering design review of all export oil and gas pipelines, shallow water risers and steel catenary risers.