Pazflor is located in deepwater offshore Angola block 17, 150km (93 miles) off the coast of Angola and 40km (25 miles) north-east of Dalia. It lies in 600m-1,200m (1,968ft-3,907ft) water depths.

The development extends over 600km² (232 square miles) with a north-to-south axis of more than 30km (19 miles). Pazflor includes the Perpetua, Acacia, Zinia and Hortensia fields, which lie in the eastern portion of block 17.

The development is operated by Total E&P Angola, a wholly owned subsidiary of Total, with a 40% interest. It is partnered with StatoilHydro (23.33%), Esso Exploration Angola (block 17) Ltd (20%) and BP Exploration (Angola) Ltd (16.67%).

PAZFLOR RESERVOIRS

The project will target development of hydrocarbons in two independent reservoir structures.

The Oligocene reservoirs are located in water depths from 1,000m to 1,200m. They contain light oil of around 35°-38° API oil and will be developed using a production loop including riser bottom gas lift. The Miocene reservoirs, in 600m to 900m waters, contain heavy oil of around 17°-22° API, which will be recovered using subsea gas / liquid separation and liquid boosting.

The overall development currently envisages 49 subsea wells connected via subsea production, injection lines and risers to a spread moored FPSO. The topside control system is designed to accommodate further 21 wells and a fourth subsea separation unit. These subsea wells will be connected via subsea production, injection lines and risers to a spread moored FPSO.

FMC will deliver 49 subsea trees (25 production, 22 water-injection and two gas-injection trees) and 49 wellhead systems. In addition, the company will supply three four-slot production manifold systems, a production control and umbilical distribution system, gas export and flowline connection systems, ROV tooling and local support for installation and start-up activities. Deliveries will be completed over a multi-year period and are expected to commence in 2009.

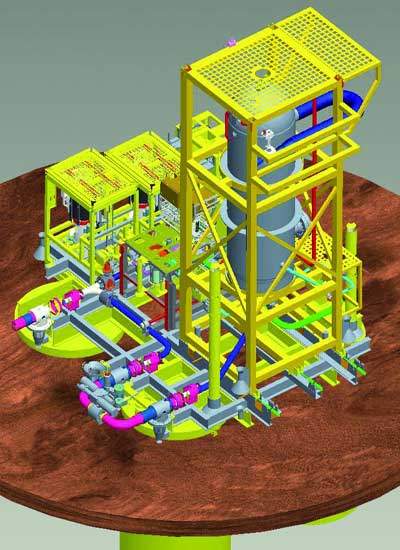

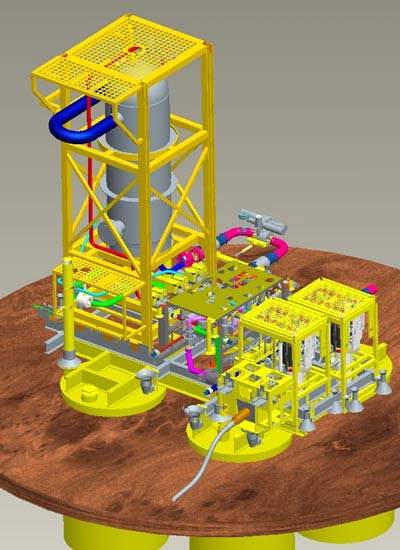

There will be three subsea separation systems provided by FMC following the company’s success on Tordis. A main difference between the two is that separation modules will be vertical and not horizontal, which provide a smaller footprint.

FPSO

Total awarded Daewoo Shipbuilding and Marine Engineering (DSME) the engineering, procurement, and construction contract for the vessel’s moorings, hull, and topsides. In turn, Daewoo awarded KBR, the contract to provide topsides engineering, procurement and interface design services for the FPSO.

Pazflor will use a purpose-built FPSO with a topside weight of 35,494t. It is designed with a processing capacity of 200,000bpd of oil, 150mmcf/d of gas, and a storage capacity of about 1.9 million barrels of crude.

DSME will construct the vessel at its fabrication yard in South Korea. Facilities are planned for a 20-year design life, and quarters are provided for 220 operation and maintenance personnel.

Total awarded a $1.1bn contract for subsea work to a consortium led by Technip with Acergy. Technip is responsible for engineering, procurement, fabrication and installation of more than 80km (50 miles) of production and water injection rigid flowlines, flexible risers and integrated production bundle risers, plus engineering, procurement and fabrication of 60km (37 miles) of umbilicals.

Installation is scheduled for 2010 using Technip’s Deep Blue and Deep Pioneer.

Acergy will be responsible for engineering, procurement, fabrication, and installation of 55km (34 miles) of water injection, gas injection, and gas export lines, umbilicals, and 20 rigid jumpers, plus installation of all manifolds, three subsea separation units with umbilicals and FPSO mooring lines.

Drilling is scheduled to start in 2009 with oil production in 2011.