The Peregrino oil field is located in licences BM-C-7 and BM-C-47, approximately 85km offshore Brazil, in the Campos basin, in water depths of 100m.

The Peregrino oil field is operated by Equinor with a 60% working interest together with its partner Sinochem holding 40% interest. The Peregrino phase two development will increase the economic life of the field and add approximately 250 million to 300 million barrels in recoverable resources to the Peregrino field.

Peregrino is Equinor’s biggest operated oil field outside Norway and has a production capacity of 100,000bpd. Concession period of the field extends up to 2040.

A plan of development for Peregrino phase two was submitted to Brazil’s National Agency of Petroleum, Natural Gas and Biofuels (ANP) on 30 January 2015. The second phase is expected to be developed with an investment of $3bn, and the first production from the phase is scheduled in 2022.

Discovery and reservoir details

The Peregrino field was discovered in 1994 and the phase one development plan was approved in 2007 by Brazilian authorities.

Phase two involves the development of the BM-C-47 block that consists of C-M-529 and C-M-530 sub-blocks, and BM-C-7 block, which was declared commercially viable in 2013 after drilling the 3-Stat-8-Rjs appraisal well in the Peregrino South discovery.

The appraisal well encountered 85m of high-quality, oil-filled sandstone reservoir present in the carapebus formation. The well experienced a net pay of more than 70%.

Peregrino phase two development details

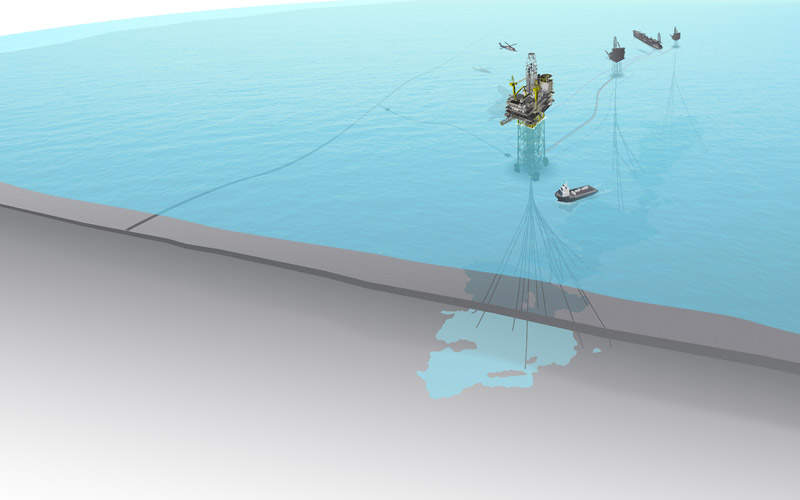

The second phase involves the development of Peregrino south-west area, which is not accessible by the existing A and B platforms. The development plan includes the installation of a fixed wellhead platform (WHP-C) and increasing the number of production wells in the new area by drilling 15 oil producers and six water injectors.

The WHP-C was installed in water depths of 120m for drilling the production and injection wells. It is the third wellhead platform in the field.

The field is being developed using horizontal production wells with artificial lift that is provided by subsurface down-hole electric submersible pumps (ESP). Multiphase export booster pumps are installed to pump oil, gas and water to be carried by export pipelines to the existing floating production, storage and offloading (FPSO) unit for processing. Produced water will be returned after the separation process to the WHP-C for reinjection.

TechnipFMC’s deepwater pipelay and construction vessel, Deep Blue completed the subsea pipelaying work for the project in 2019. The installation of the WHP-C was completed, using Heerema’s Sleipnir, the world’s largest semi-submersible crane vessel, in January 2020. The GranEnergia’s Olympia flotel has been connected to the platform to temporarily accommodate 880 individuals during the offshore execution phase.

WHP-C includes drilling facilities, utilities, power generation, living quarters and helideck.

Details of Peregrino phase one

The first phase of development included two fixed drilling and wellhead platforms along with an FPSO unit. A total of 40 producer wells were drilled using advanced horizontal well technology. Produced liquids are transferred from the wellhead platforms to the FPSO for processing. The field started production in April 2011.

Contractors involved

WorleyParsons was awarded an engineering and procurement management (EPma) contract, which is being executed by its offices in Europe and CNEC WorleyParsons in Brazil. Work includes engineering, procurement, and management assistance.

IKM Ocean Design was selected to perform SURF and a concept and FEED study. Spectrum was subcontracted by WorleyParsons to conduct project studies, including an ‘initial concept noise and vibration study’.

KCA Deutag’s rig design and engineering subsidiary, RDS, was contracted to perform FEED for the phase two development. The work is being performed from RDS’ London office.

Heerema Fabrication Group is responsible for the procurement and construction of a new jacket for the Peregrino phase two development project.

Technip FMC was awarded the engineering, procurement, construction and installation (EPCI) contract for the subsea pipeline connection for the new wellhead platform of Peregrino phase two project.

GranIHC, a joint venture between Brasilian GranInvenstimentos and Royal IHC was awarded the contract for the offshore hook-up and commissioning works related to the Peregrino WHP-C.

Schlumberger was engaged to provide the services for well construction, drilling management, and advanced digital technology solutions to construct the WHP-C. Kiewit Offshore Services was contracted for the design, procurement and construction of platform C. B&W Energy Services performs the oil flushing services of the rig’s drill deck, as well as in the utilities for the project.

Leirvik was contracted to deliver the living quarters module for WHP-C. The scope of work includes a 2.600m² five-floor accommodation module with 120 beds capacity, recreation areas, change rooms, helicopter deck, lifeboats and other facilities necessary to operate an offshore hotel.