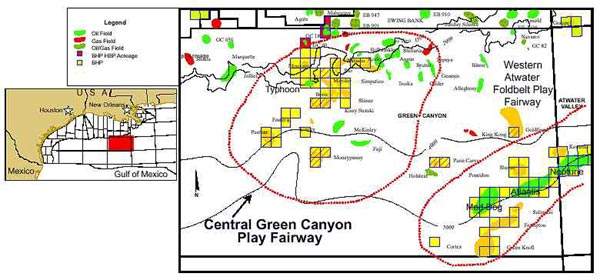

The Phoenix (formerly Typhoon) oilfield is located in blocks 236 and 237 in the central Green Canyon area of the Gulf of Mexico.

The region lies approximately 100 miles off the coast of Louisiana, US, in water depths of 2,000ft.

The field’s tension leg platform (TLP) was damaged during a hurricane in 2005. The structure was turned turtle and mooring was lost.

Typhoon was acquired by Energy Resources Technology (ERT) in 2006 from Chevron, BHP and Noble Energy for redevelopment, and the project was renamed Phoenix.

The acquisition made ERT the field’s sole operator with a 100% interest. A 30% interest was later sold to Sojitz GOM in 2007.

The operator is redeveloping the field by installing an FPU. The field’s production is expected to start in 2010.

Helix Producer I FPU

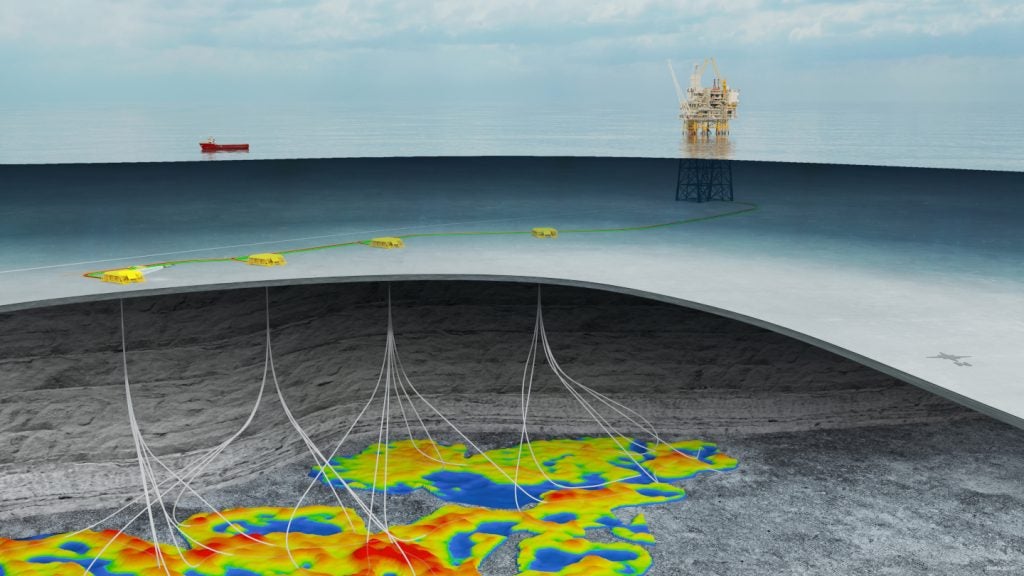

The Phoenix field will be deploying a dynamically positioned (DP), ship-shaped FPU known as Helix Producer I.

The unit was designed with a nominal capacity of 30,000 barrels per day (bpd) and features a maximum oil production capacity of approximately 45,000bpd.

Itis expected to be deployed by the second quarter of 2010.

Helix was contracted to provide the FPU after the hurricane.

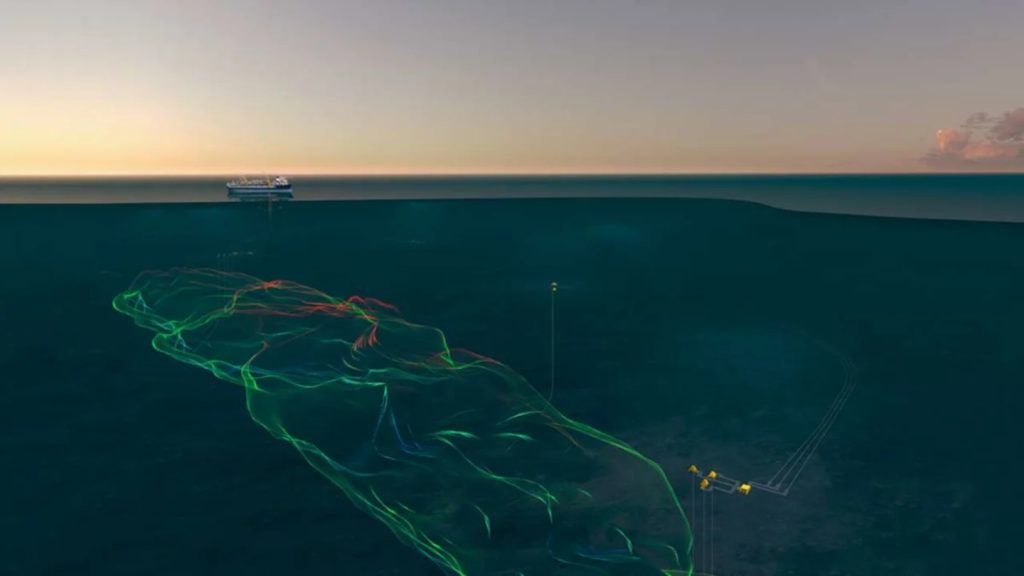

The work started with recovery of the original flowlines, risers and umbilicals that had fallen to the sea floor, as well as the repair of the oil and gas export pipelines.

Helix has also proceeded with transformation of M / V Karl, an ice-class train ferry, into an FPU.

The upgrade development involved the integration of six 12MW electric thrusters and dual 4,000lb hydraulic thrusters for dynamic positioning.

The disconnectable turret system (DTS) buoy was installed by Helix’s Q4000 drilling vessel.

A 2,500t production module was installed and module interconnection is now in process.

The converted 161.5m-long vessel is owned by Kommandor LLC, which is a joint venture (JV) between Helix and Kommandor Rømø A / S.

Phoenix field development

Phoenix will be developed as a series of subsea wells tied to the Helix Producer I FPU.

The existing eight wells from Typhoon will also be completed as subsea and tied to the FPU.

The average production from two Typhoon wells and two Boris wells was 13,000 barrels of oil per day (bopd) and 21 million cubic feet per day before the hurricane.

Two other wells, Typhoon #4 and Little Burn, were not in production at that time. Another well is expected from Phoenix.

Initial production was planned to come from four wells tied to the FPU.

Subsea system

The operator planned to use the existing wellhead equipment and new umbilicals, while new flowlines and jumpers were installed as part of the subsea production system.

Installation of the riser will be carried out by the Helix Intrepid pipelay vessel.

Topsides and risers

The topsides were designed and produced by Oil Field Development Engineering.

Fabrication and integration was carried out by Kiewit Offshore Services.

Flexible Engineered Solutions provided the riser hang-off structure and buoy for the FPU.

The riser system consists of four disconnectable risers: two for production, one for oil export and one for gas export.

The flexible risers were provided by Wellstream.

Contracts

Helix awarded the contract for commissioning services and the provision of offshore personnel for the FPU to Wood Group in December 2009.

The ten topside production modules will be installed over the hull in Ingleside, Texas, US.

A letter of indent for the supply of flexible risers and jumpers for the project was given to Wellstream International by ERT in October 2006.

The agreement covered two production risers, one oil export riser, one gas export riser and four production jumpers.