Safaniya oil field, located 200km north of Dhahran in the Persian Gulf, Saudi Arabia, is one of the largest offshore oil fields in the world, with 37 billion barrels of oil reserves.

The oil field is owned and operated by the state-owned oil company Saudi Aramco. It was discovered in 1951 and brought on stream in 1957.

Safaniya field’s production capacity is between one and 1.5 million barrels of heavy crude oil a day.

The ageing offshore field is currently undergoing expansion and upgrade to maintain its production capacity under the Safaniya Master Plan initiated by Saudi Aramco.

Safaniya field geology and reserves

Saudi Arabian offshore project is located in the northern region of the Arabian Gulf and spreads across a 65km-long and 15km-wide area.

The vertical depth for potential production from the reservoir ranges between 4,000ft and 7,000ft.

Safaniya oil field represents an anticline structure and is comprised of sandstone and shale of the Wasia formation.

The offshore Safaniya reservoir was estimated to contain 5,360 billion cubic feet of natural gas and 37 billion barrels of oil.

Early production at Safaniya

Plans for the construction of the Safaniya production facilities were first proposed in 1954. The oil field began producing 50,000 barrels of oil a day from 18 wells in April 1957. The daily output of the field was increased by seven times in 1962 with 25 producing wells.

Safaniya offshore field infrastructure

Safaniya field is operated with a series of platforms of different sizes, varying from a single well to eight-well configurations.

The field had 624 total wells as of 1993 with additional wells drilled further. It also witnessed approximately 350 well tests during 1999-2000 for well performance monitoring and future planning purposes.

It uses both offshore and onshore gas-oil separation plants (GOSP). Four offshore GOSPs are present in the field.

The site’s offshore facilities are undergoing an expansion and upgrade programme in order to sustain the production capacity of the field.

Safaniya Master Development Plan details

The heavy crude-oil-producing, mature offshore field is being upgraded in two phases as part of Saudi Aramco’s Safaniya Master Development Plan to maintain the field’s production level of approximately 1.2 million barrels a day.

Phase one of the development plan envisages the upgrade of crude-gathering facilities, improving the site’s crude oil transport capacity and providing adequate power supply for central and north Safaniya.

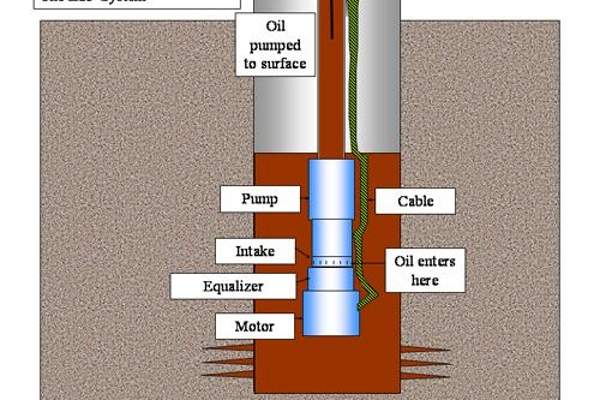

The second phase involves the upgrade of existing wellheads and the installation of artificial lift infrastructure such as electric submersible pumps (ESPs).

Details of Safaniya Phase 1 upgrade

The first phase of the field upgrade, according to the master development plan, involved the installation of a new tie-in platform and the construction of a 42in-diameter, 53km-long trunk line to transport crude from the new platform to the onshore GOSP.

The new tie-in platform Safaniya TP-20, which is Saudi Aramco’s largest ever with the topside weighing 6,000 metric tonnes, was installed in December 2012.

It was energised on 25 June 2015 via a 46km-long 230kV submarine composite cable, which is one of the longest of its type in the world.

The TP-20 platform is anticipated to receive 152MW of electric power through the submarine composite cable from Saudi Electricity Company’s 380/230kV onshore substation.

The platform was fabricated at Jebel Ali and was installed at Safaniya using the float-over installation technique. It serves as the primary crude oil gathering and power supply hub for the north Safaniya field.

A part of the new trunk line was laid with the use of horizontal directional drilling technology instead of seafloor dredging.

In addition to the T-20 platform energisation, TP-18 and nine wellhead platforms in central Safaniya field were also energised.

TP-18 receives 62MW of electric power via a 44km-long, three-core 115kV submarine composite cable from a 230/115kV onshore substation.

Contractors involved

McDermott was awarded the engineering, procurement, construction and installation (EPCI) contract worth $1bn in March 2010 for the infrastructure upgrade and electrification project at Safaniya.

The contract includes the installation of the new Safaniya TP-20, a new electrical deck module for the existing platform (Safaniya TP-18), the 53km trunk line and 156km of subsea electrical cable, as well as new control and communication systems at the field.

McDermott was also awarded a contract to provide EPCI services at Safaniya field in November 2017.

The contract includes the design, fabrication, installation, and pre-commissioning of nine slipover jackets, ten production deck modules an electrical distribution platform, in addition to associated cables and pipelines.

McDermott plans to build the structures at its Dammam and Jebel Ali facilities, and deploy vessels from its global fleet during the installation phase.

Telecommunication work for the upgrade project was subcontracted to 3W Networks by McDermott.

MSi Kenny performed the flow assurance assessment in detail for the new trunk line.