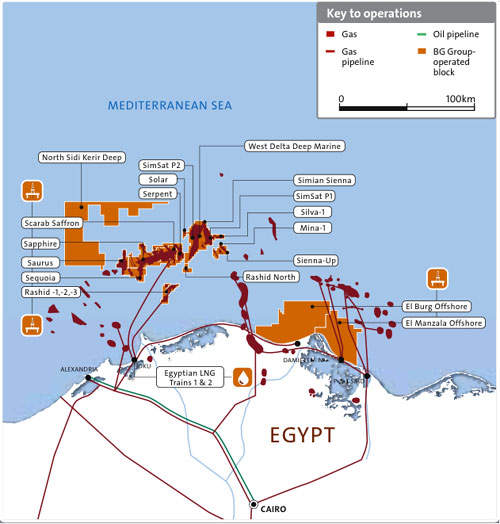

The Sequoia subsea development is located 130km northeast of Alexandria in the Mediterranean Sea and lies in water depths ranging from 70m to 570m, across the boundary of the West Delta Deep Marine (WDDM) and Rosetta concessions, which were awarded in 1995.

UK company BG Group holds a 62.99% unit interest in Sequoia. Malaysian state-owned Petronas and Edison International of the US hold 28.35% and 8.6% respectively.

The $1bn project consists of six subsea wells, three in each concession. South Sequoia includes the wells in Rosetta and North Sequoia comprises those in the WDDM.

The main reservoirs in the WDDM are Plio-Pleistocene and Pliocene sands, which extend north-east to offshore Gaza and offshore Israel, and are said to contain 7.8Tcf of recoverable gas. Rosetta’s unconsolidated sand beds are reported to have proven reserves of 2Tcf.

The composition of the gas from both concessions is largely similar, with less than 0.5% impurities, and very dry – less than 1bbl condensate per mmscf.

Sequoia is the latest phase of BG Group’s development of Rosetta and the WDDM.

Rosetta started production in 2001 and supplies Egypt’s domestic network. BG Group sanctioned the Rosetta Phase III field development plan in 2006 and delivered first gas from the project in Q1 2008. This project consisted of five wells tied back to the first two phases of Rosetta.

Sequoia was sanctioned in Q2 2008, and first gas was produced in early August 2009.

The Sequoia subsea facilities are tied back to both Rosetta and WDDM concession facilities, with hydrocarbons exported via both concessions.

On the Rashid facility in Rosetta, production from the three new South Sequoia wells is commingled in a new subsea manifold and exported about 23km via a 22in pipeline to an existing manifold (Rashid M1). The pipeline was tied into a pre-installed spare connection on Rashid M1.

Power, signals and hydraulics are provided via a new 23km main umbilical also connected between the South Sequoia wells and Rashid M1.

Production from the three new North Sequoia wells in the WDDM is commingled in a new manifold (North Sequoia manifold) that is connected via 20in jumpers to an existing subsea manifold on the WDDM’s Sapphire well.

Power, signals and hydraulics are provided via a new subsea distribution assembly (SDA) that was installed as part of the Sequoia project. This new SDA is tied into the existing Sapphire SDA via electro-hydraulic flying leads.

The gas is transported to the onshore Egyptian LNG (ELNG) plant via existing 24in pipelines from Rashid and the WDDM. Once onshore, BG Group says, minimal processing is needed because of the low level of impurities in the gas.

Key onshore processes, however, include liquid separation and further drying of the gas. Fines removal process equipment is included in the WDDM inlet facilities, and the Rosetta and WDDM onshore plants include compression units to export the gas to Egypt’s national grid.

BG has declined to give details of Sequoia’s gas production, saying only that the project is designed to make up for a natural decline in the company’s production and maintain its Egyptian gas output levels at about 2.4bcfd, which is about 40% of the gas produced in the country.

The Sequoia development was managed by Burullus Gas, the WDDM joint operating company formed by BG (25%), the Egyptian General Petroleum Corporation (EGPC, 50%) and Edison (25%) to undertake exploration and field development operations on behalf of the WDDM concession holders.

The main subsea engineering procurement installation and construction (EPIC) contract was awarded to Italy’s Saipem, which subcontracted EGPC affiliate Petrojet to complete most of the structures’ fabrication and all concrete pipe coating. Most of the marine activities were carried out by Saipem’s FDS vessel using J-lay and S-lay to match the operational environment.

The field is expected to have a life of 25 years.

In May 2009, BG Group said that it was looking to sanction another $1bn WDDM development project (Phase 7) by the middle of 2009, and potentially to begin a $2.5bn Phase 8 offshore development project in 2010. As with Sequoia, these projects are designed to maintain overall plateau production.