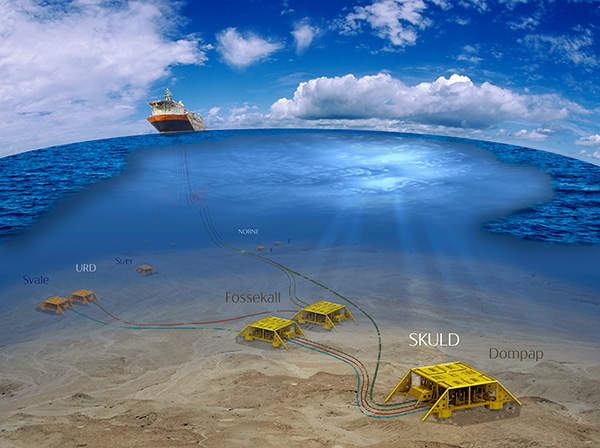

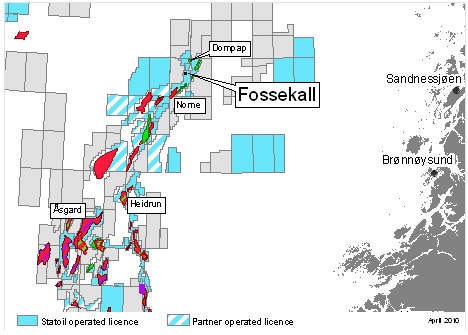

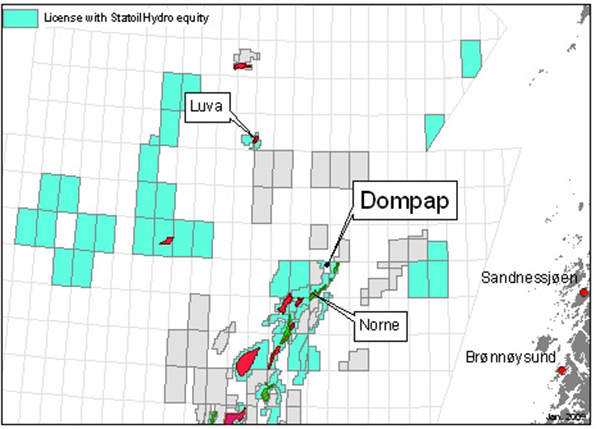

Skuld offshore field, formerly known as Fossekall / Dompap, is located within the Halter Bank area, north of the Norne Field in blocks 6609/10 and 6608/11 in the Norwegian Sea. The field is situated in water depths of about 360m.

Statoil is the owner and operator of Skuld, with a 64% interest, while Petoro and Eni are its partners and hold 24.5% and 11.5% interests respectively.

Skuld is one of the five fast-track developments that Statoil has brought into operation. It is the fifth and the largest of these fast-track developments, with production set to cover more than half of the total production from the five fields.

The overall investment for the development of Skuld is expected to reach NOK9.8bn ($1.65bn). Statoil received the consent from the Petroleum Safety Authority of Norway to operate the production facilities in December 2012. Production commenced in March 2013 and is expected to continue until 2030.

Geology and reserves of the Skuld field

The Skuld development project covers two prospects, namely Dompap and Fossekall. Oil was discovered in the Dompap region in 2009, while oil and gas were discovered in the Fossekall region in 2010.

The exploration well in the Dompap region was drilled to a depth of 3,158m below sea level and 334m of water. The exploration well in Fossekall region was drilled to a depth of 2,749m below sea level and 352m of water.

Oil and gas at the Fossekall prospect and gas at the Dompap prospect are found in the Are formation in the lower jurassic rocks. The Skuld field is estimated to hold 90m barrels of reserves.

Developing the Norwegian offshore field

Skuld has been developed with three subsea templates, six wells and three water injection wells.

The offshore field is tied to the Norne production vessel through a 26km insulated production line and umbilical measuring 14in in diameter. With the discovery of the two prospects, the lifespan of the Norne field has also been extended by five years, from 2016 to 2021.

The project implements the direct electric heating (DEH) system for the smooth flow of gas and oil through the pipeline. The system allows alternating current (AC) to pass through the pipeline walls, providing temperature control to avoid the formation of wax and hydrate.

The plan for development and operation (PDO) of the Skuld field was submitted in 2011 and was approved in January 2012 by the Ministry of Petroleum and Energy. The first subsea tree for the project was installed in November 2012.

Drilling works for Statoil’s oil and gas project

Drilling works for the exploratory wells were conducted using Diamond Offshore’s rig Ocean Vanguard. The first subsea tree at the project site was installed using the subsea inspection, maintenance and repair (IMR) vessel Edda Fauna, which used equipment weighing 50t. The installation was carried out by DeepOcean.

Contractors involved with Statoil’s Skuld field

The engineering, procurement and construction (EPC) contract for the Skuld offshore field development was awarded to Aker Solutions. The NOK1bn ($180m) contract primarily involved supplying the template manifolds and subsea trees, including control and tie-in systems.

The subsea trees and template manifolds were fabricated and manufactured in Norway itself, while the control system was manufactured in Aberdeen, UK.

Baker Hughes was contracted to provide certain drilling works for the Skuld offshore field. The contractual scope includes directional drilling, measurement and logging works, mud logging, onshore support and engineering services. The contract is being implemented as part of a larger contract, under which the company is providing drilling services for 25 fields within the Norwegian Continental Shelf (NCS).

Pipe laying and marine works for the project were carried out by Subsea 7. The contract value was NOK970m ($175m). Subsea 7 also supplied the glass reinforced polymer (GRP) covers, riser base, pipeline end terminations (PLET), In-line Tee and line pipe

coating for the project.

Emerson Process Management successfully deployed for the first time its Roxar Downhole Wireless PT Sensor System at the Skuld offshore field in 2014. The sensor, fitted behind the casing, helps to monitor the temperature and pressure in the subsea well in real time.

Aibel carried out the required modifications to the Norne vessel to enable it receive production from the Skuld field. Nexans supplied the DEH system for the pipelines and also the piggyback cable for the project.

Related content

Tyrihans Oil and Gas Field, Norwegian Sea, Norway

Tyrihans is located in the Halten Bank area of the Norwegian Sea, 35km south-east of the Kristin field, in roughly 285m of water.

Åsgard, Norwegian Sea, Norway

The Åsgard oilfield lies on the Haltenbank in the Norwegian Sea, 200km offshore Norway and 50km south of Statoil’s Heidrun field.