Trestakk is an oil and gas field located in the Norwegian Sea in block 6406/3. The field lies in production license PL091, approximately 27km south-east of Åsgard A. The water depth in the region is estimated to be 300m.

Equinor operates the field with 59.1% ownership interest, while the other licensees are ExxonMobil and Production Norway (33%) and Vår Energi (7.9%). A concept for the field’s development was selected in 2015 and was approved by the Norwegian authorities.

Halliburton was awarded the contract in June 2018 to provide integrated drilling and well services for the Trestakk field. Production drilling and modification works were conducted in 2018 and oil and gas production from the field commenced in 2019. Equinor developed the field with an estimated cost of NOK5bn ($585m). The life expectancy of the field is approximately 12 years.

Trestakk field discovery and reserves

The Trestakk oil and gas field was discovered in 1986 by drilling the exploration well 6406/3-2, while an appraisal well, 6406/3-4, drilled in 1987 confirmed the presence of hydrocarbons.

The field is segmented into four divisions that belong to the Yarn structure. Located 4,000m below sea level, the field’s reservoir has medium pressure and temperature and consists of Middle Jurassic sandstones in the Garn Formation. The shallow marine sandstones have calcite-cemented intervals and are identical.

Trestakk field holds 14.6 million cubic metres (Mm³) in resource oil and 3.7GSm³ in associated gas and is expected to produce 22.2GSm³ of gas over its lifetime. Gas produced from the field will be injected into the reservoir. Approximately, 18.5GSm³ of gas is estimated to be injected into the reservoir.

Trestakk field development details

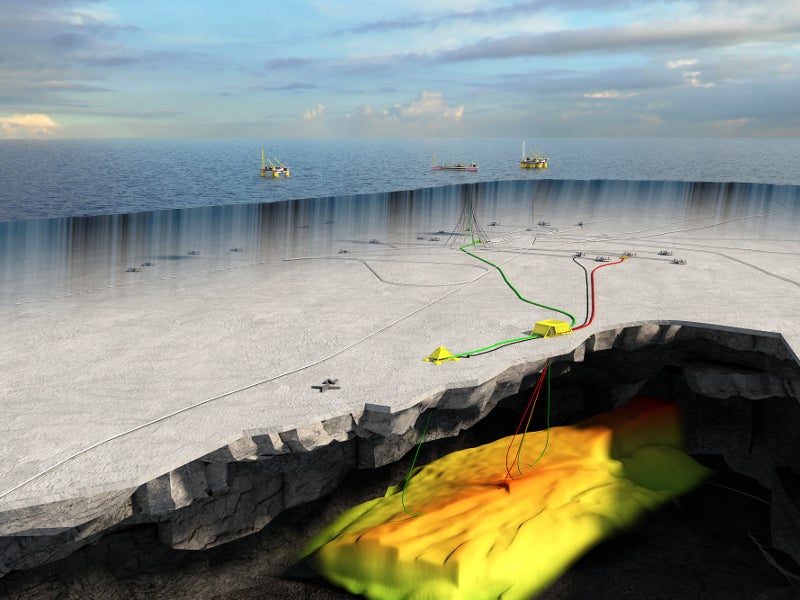

The field was developed using five subsea wells, including three production wells and two gas injection wells, tied back to Åsgard A FPSO.

The installation included two templates with four slots each with a direct link to Åsgard A. The northern bay frame consists of three production wells, while the two gas injection wells are located in the southern bay frame.

Recovered hydrocarbons are processed at Åsgard A FPSO and the gas is injected using the R-frame. A 25.2km-long production line with an inner diameter of 12.6in connects the Trestakk field to the Åsgard A FPSO lying towards the south.

An electric heating cable was installed on the production line for linking the southern bay frame to Åsgard B, through Åsgard A. The approximately 30.2km-long cable comes with an insulation coating and comprises chromium steel.

A new flexible riser and other associated subsea structures were installed at Åsgard A FPSO as part of the project. A semi-submersible drilling rig was used for the well drilling activity, which was completed in 640 days.

Key players involved

A contract for subsea front-end engineering and design (FEED) study for the Trestakk field was awarded to Forsys Subsea, a joint venture between FMC Technologies and Technip. The contractual scope includes all systems and related services from the wellhead to Åsgard A riser hang-off, including umbilicals, riser, flowlines and subsea production system installed and made ready for operation.

Forsys Subsea also provided an optimal technical and cost-efficient development solution, along with a well-defined basis for the development phase under the terms of the contract.

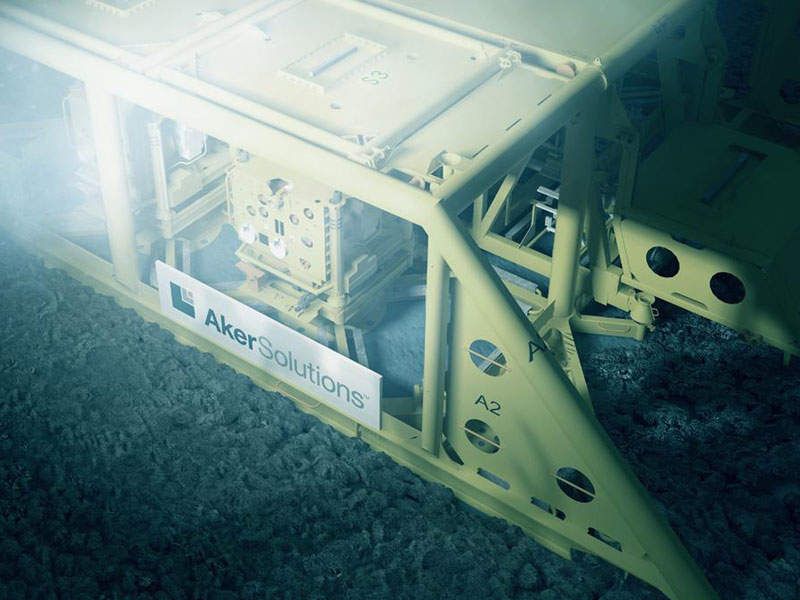

Aker Solutions was selected to perform a front end engineering design (FEED) contract for the Trestakk field tie-in to the Åsgard A production vessel in the Norwegian Sea. The contract also comprised of an engineering, procurement, construction and installation (EPCI) option.

Aibel manufactured the Trestakk template and satellite at its Haugesund facility.