Varg field is situated at a depth of 84m in block 15/15 in the North Sea, Norway. The field was discovered in 1984 and the first oil was produced in December 1998.

Talisman Energy Norge is the operator of the field with a 65% interest. Other partners are Petoro (30%) and Det norske (5%).

Petrojarl Varg FPSO

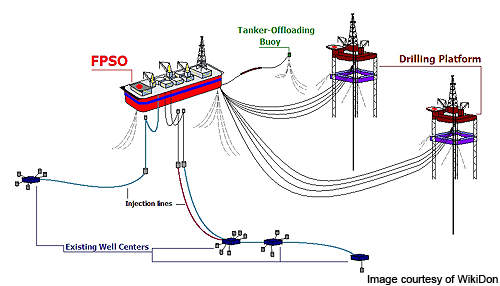

The Petrojarl Varg is a turret-moored FPSO featuring processing facilities for oil production, gas injection and water injection. The FPSO has a production capacity of 60,000bopd and a storage capacity of 470,000 barrels of oil.

Petrojarl Varg is connected to a wellhead platform through flexible flowlines and umbilicals. The flowlines are used for oil production and water and gas injection. The umbilicals provide power supply and control, and oil from the FPSO is transferred to shuttle tankers through a discharging system.

In September 2009, Petrojarl Varg was acquired by Teekay Offshore Partners from Teekay Corporation for $320m. Teekay Offshore Partners was created by Teekay in 2006 to provide marine transportation and storage services to the oil industry.

Varg oil reserves

The field was originally estimated to contain 30 million barrels of oil equivalent (MMboe). Redevelopment in 2004 increased the field’s reserves to 88MMboe. With new discoveries made in the field area, recoverable reserves are now estimated at 95MMboe. Proven and probable reserves are estimated at 16.5MMboe.

Field development

The licence to explore the field was first acquired by Statoil and Norsk Hydro in 1975. The field was developed using an unmanned wellhead platform, Varg A. The platform is connected to the Petrojarl Varg FPSO.

Most of the wells used to produce oil from the field are vertical or deviated cased with short pay zones. There are also horizontal wells, the longest being 1,000m. All the wells produce from different formation zones. The gas produced at the field is re-injected to enhance oil recovery. In the future, gas will be exported.

Development of the field was difficult due to its complex faulting, which included several isolated substructures. Inadequate seismic data due to salt tectonics added to development problems. Due to these issues, the developers found it difficult to produce oil from the field. As the water-to-oil ratio increased and the oil pressure decreased, the developers decided to decommission the field in 2001.

In 2002, Pertra, a subsidiary of Petroleum Geo-Services (PGS), acquired the rights to the field for $1m. Pertra became responsible for the decommissioning of the field. In order to increase oil production, Pertra contracted AGR Group to provide its drilling petroleum technology.

AGR conducted an extensive 3D seismic survey and combined it with the existing seismic data to identify new production and injection wells. Five production and two injection wells were drilled using this data. Following redevelopment, daily production from the field increased from 13,000-14,000bopd to 30,000bopd.

Pertra conducted further exploration of the field in the Varg Vest segment. One appraisal and one exploration well were drilled which helped in increasing the life of the field. In 2005, PGS sold Pertra to Talisman which became the operator of Varg.

In December 2009, total output from the field increased from 11,600bopd to 26,000bopd following the drilling of a new production well A-10A.

The well encountered 150m of oil pay. Talisman is planning to drill new production wells in 2010.

Varg field geology

The Varg field reservoir is made of Oxfordian sandstone from the Jurassic period. It is a simple force fold containing upper and lower sand structures separated by a middle siltstone structure. Faults in the reservoir were responsible for the variations in the structure and topography.

Contracts

In 1999, Norsk Hydro and Schlumberger provided their services for fault resolution of the field. Using their Variance Cube software, the companies provided the operators with better structural and stratigraphic interpretation.

Wärtsilä signed an agreement with PGS in 1999 to maintain the power production on several vessels including the Petrojarl Varg FPSO.

In December 2009, Teekay signed an agreement with Aibel for future modification of five FPSOs, including the Petrojarl Varg.