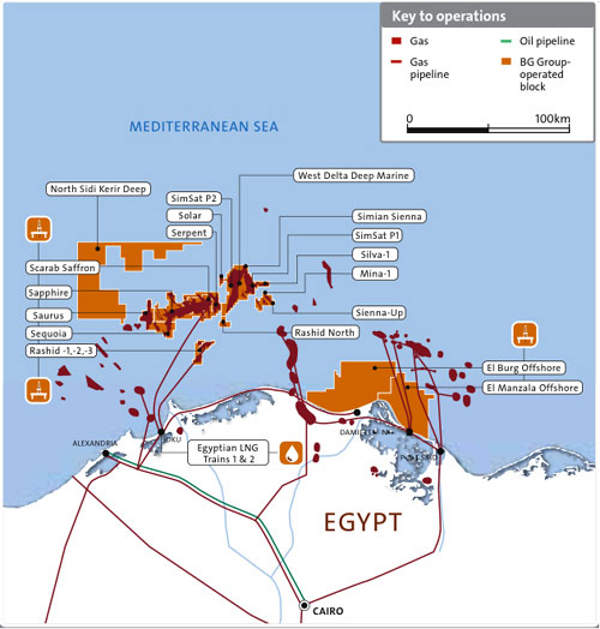

West Delta Deep Marine (WDDM) concession in the Mediterranean Sea comprises 19 gas fields, of which 12 fields (Scarab, Saffron, Simian, Sienna, Sapphire, Serpent, Saurus, Sequoia, SimSat-P2, Sapsat-1, Sapsat-2 and Swan) are in production. The fields are located at water depths ranging from 700m to 850m and approximately 90km to120km from the shore.

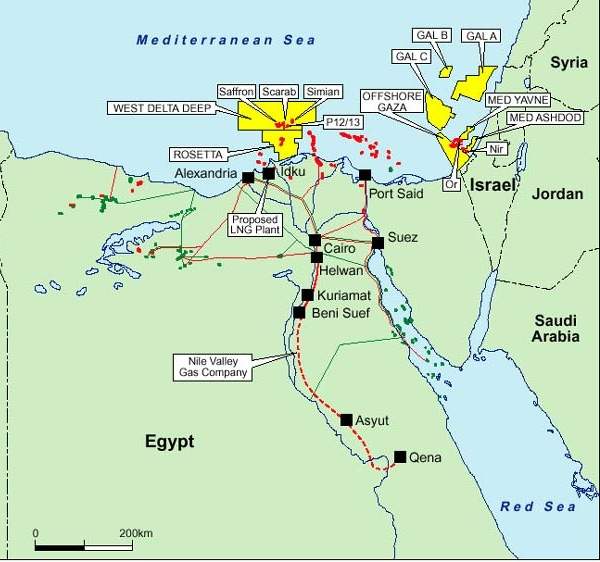

The operator BG Egypt won the WDDM concession in 1995. It holds a 50% interest, while the remaining 50% interest is held by Petronas, which acquired Edison International’s share in 2003. Burullus Gas Company, a joint-venture (JV) of EGPC (50%), BG Egypt (25%) and Petronas (25%), carries out the operations on behalf of the WDDM partners.

WDDM fields discovery

Scarab and Saffron fields were discovered in 1998 and March 1999 respectively, Simian and Serpent fields were discovered in 1999, Sapphire and Sienna were discovered in 2000, Saurus was discovered in 2001, Solar was discovered in 2002 and Sienna Up, Mina and Silva were discovered in 2006.

Initial production from WDDM

The first two fields Scarab and Saffron started production in March 2003. Eight subsea wells from the fields are connected to a subsea manifold, which is further connected to an onshore processing terminal by two pipelines of 24in and 36in diameter respectively. The wells are connected to the onshore control room through electrical and hydraulic umbilical lines.

Development of Simian, Sienna and Sapphire fields

Simian, Sienna and Sapphire fields were developed using subsea technology and a shallow water controls platform. The first production from the first two fields occurred in April 2005, while the latter started production in September 2005. A total of 16 subsea wells from the three fields are tied into the existing gas gathering network.

Further development projects at WDDM

Phase 4 development of WDDM was sanctioned in the second quarter of 2006 and the project was completed in early 2008, bringing seven additional wells into production.

Phase 5 of the WDDM development, involving the installation of two gas turbine-driven compression sets, new absorption towers and associated equipment to increase production from the Scarab and Saffron facilities, was sanctioned in late 2007 and commissioned in May 2009.

Phase 6 of the WDDM, involving the development of the Sequoia field, which also straddles the Rosetta concession, was sanctioned in mid-2008 and the first gas was produced in August 2009. The field features six subsea wells, including three wells in each concession, and is interconnected to the existing facilities at WDDM.

Phase 7, which was sanctioned in 2009, involved the installation of a 68km-long and 36in-diameter offshore pipeline, five new compressors and a power plant. The pipeline came online in 2011, while the compressors and the power plant were commissioned in January 2012.

Phase 8a, involving the drilling, completion and tie-back of an additional nine subsea wells in the area, was sanctioned in 2010. Phase 8b, which involved the drilling, completion and tie-back of seven additional wells, was sanctioned in 2011. The former was completed in October 2011, while the latter started production in June 2012.

The $1.5bn Phase 9a, involving the development of nine wells across the WDDM, was sanctioned in March 2013. The first well started production in July 2014, and as of November 2014, seven wells from the project are in operation, with the latter two slated to come online in early 2015.

The latest development project also involved the installation of new subsea facilities, two new main power distribution cables and ancillary topside controls system modifications.

Onshore gas receiving plants

Production from the Scarab and Saffron fields are conveyed to the SEGAS LNG complex in Damietta, while production from the remaining fields is conveyed through pipelines to a two-train LNG plant located near Idku, east of Alexandria. The LNG plant is separately owned by the Egyptian LNG Company.

Contractors involved with WDDM

Initial front end engineering and design (FEED) study for the development of the concession area was performed by Intecsea (formerly Intec) in 1999. The subsea and topside production control systems for three wells in the Sequoia field, including similar facilities at Sinbad, Simian, Sienna and Sapphire fields, were supplied by GE Oil & Gas subsidiary VetcoGray.

The main engineering, procurement, fabrication, installation and commissioning (EPIC) contract for Phase 9a subsea infrastructure, including flow-lines and umbilicals, was awarded to Saipem, while the subsea controls and production tree equipment were supplied by GE and One Subsea respectively. Drilling activities for Phase 9a are being performed by Saipem, Diamond Drilling and Transocean, while the long lead items for the project were supplied by Cameron and Vetco Gray.

Saipem further subcontracted ClampOn to supply its proprietary subsea corrosion-erosion monitors (CEM) for the project.

The main EPCI contractor for Phase 8b was Saipem, the drilling works were performed by Saipem, Diamond Drilling and Transocean, the subsea controls systems were supplied by Vetco Gray, controls systems for one well were provided by Aker Solutions and eight subsea trees and the subsea deepwater connector system components were supplied by Cameron.

The contract for the design and procurement of the onshore facilities for Phase 7 was awarded to ENPPI. Petrojet carried out the construction works, while Allseas carried out the deepwater pipe lay and Technip performed the hot-taps tie-in and commissioning of the offshore pipeline. Three SGT-300 gas turbine generators for the power plant under Phase 7 were supplied by Siemens while the compressors were supplied by GE.

The EPIC contract for Phase 6 was awarded to Saipem, which further subcontracted Petrojet for the fabrication of the structures and to perform concrete coating for all the piping components. The engineering, procurement and construction (EPC) contract for Phase 5 was awarded to the consortium of Enppi and Petrojet.

Hydrasun assisted GE in supplying the umbilical solutions on the Simian, Sienna and Sequoia phases, and supplied 30 infield jumpers for Phase 8a, 22 infield jumpers for Phase 8b and 26 jumpers for Phase 9a.