The Valhall field was discovered in 1975 and came online in 1982. It is operated by BP, which holds a 35.95% interest while the remaining 64.05% interest is held by Hess Norge. The water depth at the field is approximately 70m.

At project sanction, it had 247 million stock tank barrels of oil (MMboe) located in the Chalk reservoir, which has been upgraded to 1,161mmboe.

The remaining recoverable reserves at the field are estimated to be 251.8 million barrels of oil, 7.1 billion cubic metres of gas and one million tonnes of natural gas liquids (NGL).

The plan for redevelopment and operation (PDO) of the field was approved in June 2007 and the Valhall Redevelopment project, which was completed in January 2013, has extended the field life to 2050.

The redevelopment project primarily involved the construction of the new integrated processing and housing (PH) platform, which receives power from shore via a 292km-long cable from Lista. Two new unmanned platforms were also constructed at the field as part of the project.

Export facilities

The 2/4-J pipeline at Ekofisk Centre transports produced oil to Teesside, England, while gas is transported directly to Emden, Germany, through the Norpipe pipeline. Oil and gas coming from Hod are also processed at the platform.

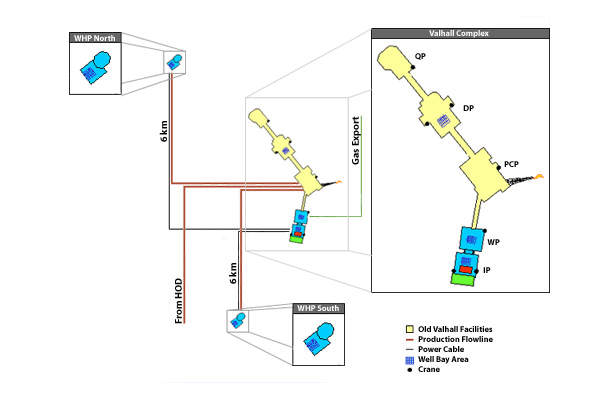

Details of the Valhall complex

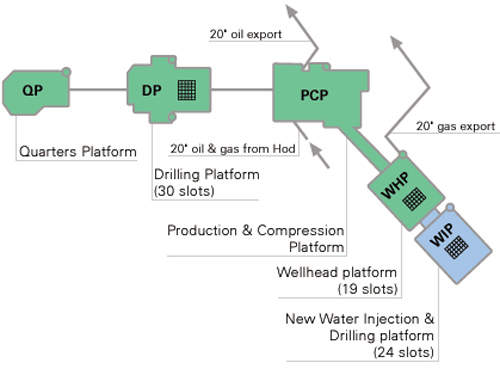

The Valhall complex comprises six separate manned platforms: the Quarters Platform (QP), the Drilling Platform (DP), the Production and Compression Platform (PCP), the Wellhead Platform (WHP), the Water Injection Platform (IP), the new combined Process and Hotel Platform (PH) and two unmanned flank platforms, Valhall South Flank platform and Valhall North Flank platform.

QP, DP and PCP were the first platforms to be commissioned at Valhall. Production from the field started in October 1982. The PCP was decommissioned in October 2013, following the commissioning of the new PH platform earlier that year.

The new PH platform has an oil production capacity of 120mbopd, can handle a gas volume of 143mmscf/day and has a total liquid capacity of 200mbpd (oil and produced water).

In April 1996, the wellhead platform (WP) was installed and the first oil was produced in June. The WP has 19 well slots and was built at a total cost of NKr1.5bn including the well drilling costs.

Valhall flank platforms

Valhall flank platforms (VFP) include two unmanned wellhead platforms (WHP) with 16 drilling slots each. The wellstreams are processed at the platforms, located 6km from the existing Valhall facilities, at water depths of 66.7m (South WHP) and 69.4m (North WHP).

West Epsilon drilled wells from October 2002 to August 2003 on the South Flank. Production on the South Flank started in May 2003 and the North Flank came on-stream in January 2004. Each platform has a provision for water injection. The platforms are powered from the main Valhall Complex and operations are monitored through a fibre-optic cable connected to the existing facilities at Valhall.

Pipelaying for the north and south WHPs was performed as a continual operation during a peak weather window in 2002. Heerema Tonsberg was the principal contractor for the WHPs, however, jackets were sub-contracted to Heerema in Vlissingen, Netherlands.

The 13% super-chrome pipeline units specified were welded together by the pipeline contractor Coflexip Stena Offshore at its fabrication site in Orkanger, Norway, before being reeled onto a vessel for offshore installation. Tie-in modification work to the Valhall production platform was carried out by Aker.

Water injection platform

The water injection platform is located at a water depth of 73m with an injection capacity of 180,000 barrels of water per day (bwpd). The platform was aimed to improve the oil recovery factor from 31% to 38%. This yields roughly 29,000,000m³ of additional oil. Total investment for the project was NKr7.2bn, including NKr1bn in piling work.

Installed in 2003, the water injection project involved linking a fixed-steel platform to the existing Valhall wellhead platform. The integrated topside has water injection facilities, seawater and produced water treatment facilities, as well as power generation. There is also a platform-based drilling rig, which can skid on beams from the wellhead platform to the wellhead injection platform, including a mud mixing module.

Drilling and maintenance of wells on the new platform (24 wells in total), as well as on the existing WP platform, is possible by the configuration of this injection platform.

Contractors involved with the redevelopment project

The front-end engineering and design (FEED) studies for the redevelopment project were performed by Fabricom and Wood Group. This included Wood Group’s sister companies Mustang Engineering and J P Kenny.

The main deck of the PH platform was constructed by Heerema and was designed by Mustang Engineering. Heerema was also involved as the engineering, procurement and construction (EPC) contractor for the flank wellhead platforms.

Workshop drawings for the PH topsides were delivered by Iv-Consult. The living quarters of the integrated platform were constructed by SLP Engineering.

The procurement, fabrication, load-out and sea-fastening of the steel jacket substructure and piles of the PH platform were performed by Aker Kværner. Installation of the platform at the project site was assisted by Saipem.

The helicopter hangars and external aluminium stair towers of the living quarters were constructed by Bayards Aluminium Constructions. The valve work on the new PH platform was performed by Score Group.

ABB supplied the HVDC Light converter stations, located at each end of the 292km-long power cable. The subsea cables for the HVDC link were supplied by Nexans.

The contract to operate and to procure and supply the field’s seismic equipment was awarded to WGP and Thalassa Energy Services, respectively. Bilfinger Industrier Norge provided insulation, scaffolding and surface protection works at Valhall.

Modification works on the IP were performed by Fabricom in 2013, with the company demolishing the exhaust tower of the platform to create more deck space.