Oseberg Vestflanken 2 is located approximately 8km north-west of Oseberg field centre and includes Alpha, Gamma and Kappa oil and gas structures. It represents the first of three planned developments for the Oseberg area’s remaining reserves.

Equinor (formerly Statoil) operates the Oseberg Vestflanken 2 project with a 49.3% stake, while other partners include Petoro (33.6%), Total (14.7%) and ConocoPhillips (2.4%). The investment on the project was reduced from Nkr8.2bn ($935.6m) to Nkr6.5bn ($798m). The field life is estimated to be in production until 2040.

The drilling of the first production well began in February 2018 and production commenced in October 2018.

The development is expected to yield 110 million barrels of oil equivalent (mboe). Of the total reserves, oil is estimated to account for 10 million cubic metres (63 million barrels) with the remaining being gas. The reservoirs are located approximately between 2,400m and 3,100m below the surface of the sea.

Oseberg Vestflanken 2 development details

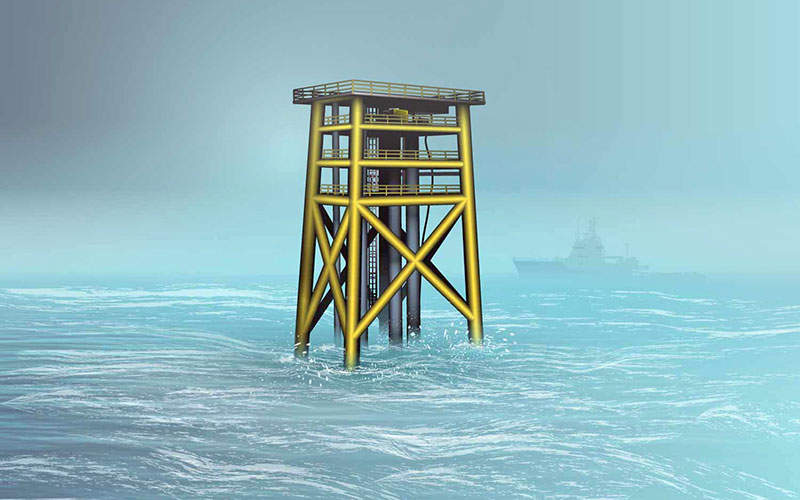

Development of the Oseberg Vestflanken 2 involved an unmanned and remote-controlled wellhead platform with ten well slots. A jack-up drilling rig, Cat-J, was employed to perform the drilling activity. Plans for the field also include reusing two existing subsea wells.

The wellhead platforms are being used for recovering both oil and gas from the new deposits, while aiding in improving the recovery rate from existing producing assets. The wellhead platforms are not equipped with any facilities, helicopter deck or lifeboats.

A new pipeline is used to transport the produce from the new deposits to the Oseberg field centre.

Maintenance work on the new wellhead platform will be performed using service vessels connected to it via gangways. The maintenance activities will involve two campaigns a year that will be performed in good weather.

The project is expected to mark a new phase in North Sea field developments, where traditional subsea infrastructure can be replaced by unmanned wellhead platforms in prospects located in water depths of 150m.

Oseberg field centre details

The Oseberg field centre consists of three platforms, namely Oseberg A, Oseberg B and Oseberg D located in the southern part of the field and connected to each other by bridges. The Oseberg C platform lies 14km north of the field centre.

Oil and condensate received at the Oseberg field centre are transported to the land-based Sture terminal through the 115km-long Oseberg Transport System, whereas the gas is injected into the Oseberg field.

Oseberg Vestflanken 2 development timeline

A decision to perform feasibility studies on the development was taken in May 2013, and was followed by consent to conduct concept studies in May 2014. The concept selected for the field development was announced in February 2015.

Equinor and its partners submitted a plan for development and operation (PDO) of the project in December 2015, and the plan was approved by the Norwegian Ministry of Petroleum and Energy in June 2016.

Key players involved

Equinor awarded the front-end engineering and design (FEED) study contract for the project to Aibel.

Dragados Offshore was also awarded a FEED contract that included design of all disciplines, including temporary structures, equipment and systems necessary for construction, yard assembly, load-out, transportation and installation. Engineering work commenced in March 2015 and was completed later in October during the same year.

Wood Group Mustang, and Mareal Engineering and Consulting provided support to Dragados in certain specialist areas.

A contract for conducting a concept study regarding the choice of an unmanned dry tree wellhead platform for the field development was awarded to Kvaerner in August 2014.

In February 2016, Heerema Fabrication Group secured an engineering, procurement and construction (EPC) contract for the unmanned wellhead platform at the project. Heerema Marine Contractors provided transport and installation services for the platform.

Technip was responsible for performing fabrication and installation of 7.5km-long, 14in production pipeline and 9km-long, 10in gas injection pipeline for the project.

Ocean Installer was contracted to perform fabrication and installation of subsea facilities for the project.

Baker Hughes and Schlumberger were awarded contracts for providing drilling and well services for the Cat-J Askepott and Askeladden drilling rigs in January 2017.