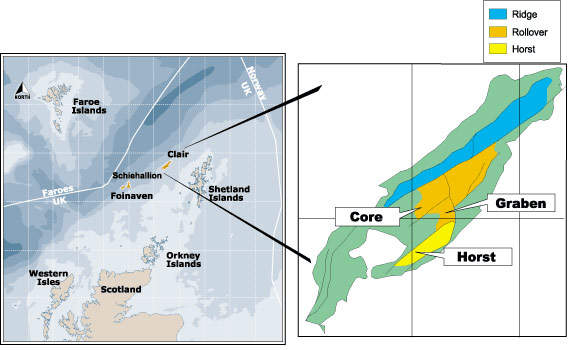

When it was discovered in 1977, the Clair field was the largest discovered but undeveloped hydrocarbon resource on the UKCS (United Kingdom Continental Shelf). The field is located 75km west of Shetland in water depths of up to 150m and extends over an area of some 220km², covering five licence blocks – 206/7a; 206/12; 206/8; 206/13a and 206/9.

Between 1977 and 1990, ten appraisal wells were drilled, followed by a further five between 1990 and 1995. A 3D seismic survey was also carried out during this period. A further two appraisal wells were drilled in 1997 and an extended well test was conducted.

In May 1997, it was agreed to jointly develop the field. Development of the field was approved in 2001, representing an investment of £650m by BP and its four partners in the project.

The five partners have the following fixed equity interests:

- BP: 28.6% (Operator)

- ConocoPhillips: 24.0%

- ChevronTexaco: 19.4%

- Enterprise: 18.7%

- Amerada Hess: 9.3%

GEOLOGY

The reservoir is made up of fractured sandstones of Devonian to Carboniferous age, with current interpretations suggesting that the total volume of hydrocarbons in place is in excess of 410 million metric tons of 22°-23° API oil.

The field is divided into nine fault-bounded segments, which have a common free water level and a maximum oil column of 600m. A gas cap is present in the structurally elevated ridge segments.

DEVELOPMENT

The Clair development is a phased one. Phase 1 has focused on the Core, Graben and Horst reservoir areas which have estimated oil in place of approximately 1.75 billion barrels, of which 250 million barrels can be recovered.

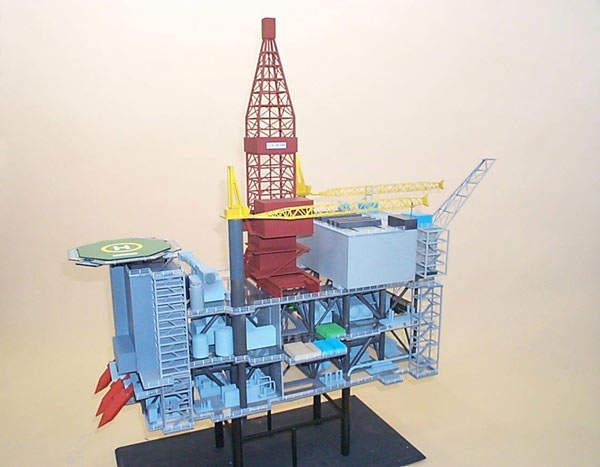

The development consists of a conventional platform with production and process topsides facilities, supported by a fixed steel jacket – the first steel-based structure in the west of Shetland area.

The facilities were installed offshore during the summer of 2004. BP says the installation of the 11,700t topsides, by a single lift, was one of the heaviest offshore lifts ever carried out in the UKCS. Commissioning was completed in January 2005.

Initial production through the original appraisal well was brought online in February 2005. Production built up to a plateau of 50,000bpd in 2007.

In 2005, BP said it estimated there were five billion barrels of oil in the field, saying it was confident that this first stage of development would allow it to unlock more of the Clair reservoir.

Oil from the field is exported to the Sullom Voe Terminal in Shetland via a 105km, 22in diameter pipeline. Produced gas is exported through a 10km, 6in diameter spur line into the Magnus enhanced oil recovery trunkline.

Noble Drilling and Wood subsidiary Mustang Engineering won the contract for Front-End Engineering Design (FEED). Ruling out a twin steel or concrete monotower design, they proposed an integrated topsides deck (including accommodation) with a separate modular drilling rig located on a single steel substructure, capable of carrying out full processing. The export concept was proposed as offshore loading or a pipeline. The jacket for Clair is located over the existing 206/8-10z well.

The jacket is a four legged single steel structure with a height of approximately 165m. Both jacket and topsides are designed for fabrication, transportation and installation as single fully integrated lifts (maximum 10,500t) that require access to the heaviest lift capability vessels on the installation market.

BP awarded the contract for the fabrication of the platform jacket to Aker Verdal. The contract for the construction of the platform topsides was awarded to Amec. There are additional processing facilities for offshore power generation, water injection, produced water and cuttings reinjection, surplus gas disposal (export or reinjection) and flare gas recovery.

Artificial lift is provided for all producing wells with the option of Electrical Submersible Pumps (ESPs) for future wells intervention and the operations feature simultaneous drilling and coil tubing well intervention operations (SIMOPS).

DRILLING RIG

The contract to build the accommodation modules was awarded to the Norwegian company, Leirvik Module Technology. The accommodation contract involved the fabrication of the living quarters and utility building, which forms part of the topsides for Clair.

The contract for the drill rig fabrication contract was awarded to Heerema Hartlepool. The scope of the fabrication work incorporated fabrication of a Derrick Equipment Set, (DES) module, with substructure and skid base and a Drilling Support Module, (DSM). The work included equipment installation and extended commissioning and the modules weigh approximately 2,500t and 2,200t respectively.

The entire structure has a design life 25 years.