Hanze was Veba Oil’s (now Petro-Canada’s) first operatorship and the largest field to be developed in the Dutch North Sea.

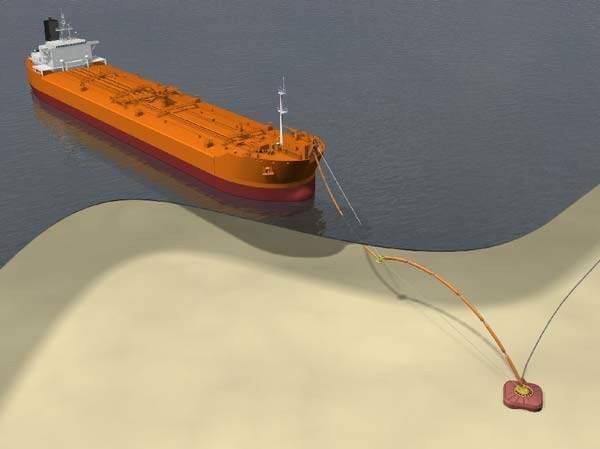

The development is based on a steel-gravity based production and storage platform. It is connected by a 1.5km-long pipeline running to a tanker-mooring and offloading facility for oil export.

This facility will be the first single-point mooring system in the Dutch sector of the North Sea.

Associated gas will be used to fuel the platform and excess gas will be transported to Den Helder, via pipelines.

Hanze lies in block F/2 in the Dutch sector of the North Sea, about 200km north-west of Den Helder.

The field has reserves exceeding 34 million barrels of oil, as well as 40 billion cubic feet (bcf) of associated gas.

The field covers 4.5km² at a depth interval between 1,340m and 1,478m below sea level.

Drilling

The field will be developed using nine wells under a four-well contract, which features an option for two additional wells.

Drilling is being carried out by the Jack-up Ensco 100 following the rig’s conversion back to a drilling mode in December 2000.

Development

The field will be developed by a production platform on a steel gravity base.

Veba placed the $150m turnkey contract with Hyundai Heavy Industries.

Hyundai subsequently subcontracted Doris Engineering to draw up detailed designs regarding many aspects of the project.

Gravity base structure (GBS)

The gravity base structure (GBS) comprises a 14m-high steel tank with skirts underneath and a framed tubular structure above.

It was designed with a semi-fixing function so as to allow it to move to other oilfields at the end of the Hanze production life.

The 15,600t steel structure was floated out to the field in August 2000 and sunk in 43m of water onto a predetermined position on the seabed.

Around 8,000t-10,000t of steel were used to manufacture the base. Upon installation, it was then filled with 30,000m3 of concrete ballast, although some of the volumes were left clear for oil storage.

The base has capacity for 150,000 barrels of oil, which is sufficient storage for keeping oil between visits from shuttle tankers to off-load the produced hydrocarbons.

The GBS is 63m-long, 56m-wide and 83.5m-high. It was loaded on-board the Mighty Servant 3 by skidding the structure on three skidbeams over the side of the vessel.

After a six-week voyage, the structure arrived in Rotterdam. Smit was the installation subcontractor and Boskalis Offshore was responsible for all seabed rectification works.

This included removing 2m of soft-top sediment around a 70m x 80m footprint to ensure that the gravity base landed on a level surface seabed, with the steel skirts penetrating the sea floor.

Boskalis dredged the seabed with the Cornelius Zanen. After the installation, Boskalis placed 32,000t of 10in rock around the base, filling up the remnant dredged pit using the fallpipe vessel Sandpiper, thereby building up scour protection.

Topsides

The integrated production deck (IPD) and the flare tower were fabricated by Hyundai Heavy Industries in Ulsan, South Korea, and transported to Rotterdam by Dockwise. The IPD weighs approximately 8,100t.

It will be installed in the Hanze field by means of a heavy-lift crane vessel. This oil production facility can produce up to 30,000 barrels of crude a day.

The IPD has a length of 56m, a width of 42m and a height of 17.5m.

It was loaded on-board the Mighty Servant 1 by skidding the structure on two skidbeams via the stern of the vessel.

Installation

Saipem won the installation contract and will use its S7000 heavy-lift crane barge to lift the IPD onto the GBS.