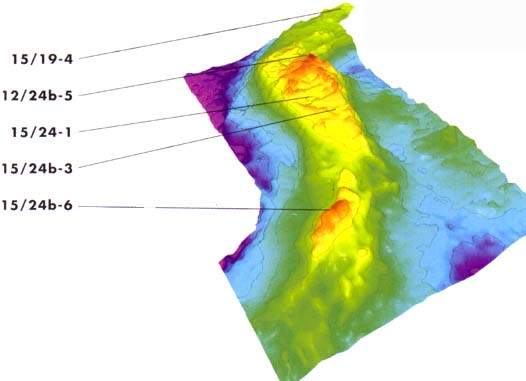

The MacCulloch oilfield lies 250km north-east of Aberdeen in UKCS block 15/24b, in a water depth of 150m.

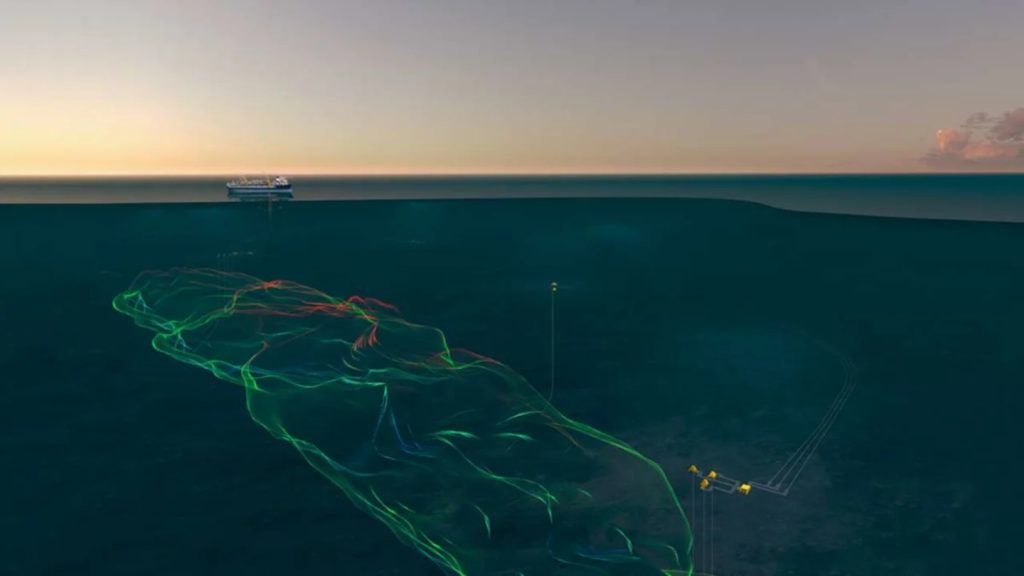

Its reservoir consists of channelled Upper Balmoral turbidite sandstones of the late Palaeocene age, which are located approximately 1,850m subsea.

The block was awarded in the 11th licensing round and is operated by Conoco (60%), with Lasmo North Sea (40%) as the co-venturer.

The MacCulloch project marked Conoco’s first use of floating production, storage and offtake technology in British waters.

Reserves

The field has recoverable reserves of approximately 58 million barrels (eight million tonnes) of 32° to 37° API gravity oil.

In addition, it contains approximately 15 billion cubic feet of gas.

At the project start-up, the field life was put at approximately five years.

Production peaked at up to 60,000 barrels (bbl) oil and 12 million cubic feet of gas per day.

Drilling

The field was originally discovered in 1990 by the exploration well 15/24b-3, when the semisubmersible Benvrackie tested a tertiary sandstone formation.

The resultant well flowed at a rate of 3,800bbl/day of 36° crude and 1.26 million cubic feet of gas. This well was followed by the drilling of two appraisal wells.

The first well, 15/24b-5, was drilled in 1991 and tested 5,464b/d of 32° API oil and 1.79 million cubic feet of gas via a 48/64in choke.

The second well, 15/24b-6, was drilled the following year.

It tested 2,954b/d 37° API oil with 0.72 million cubic feet of gas through a 36/64in choke.

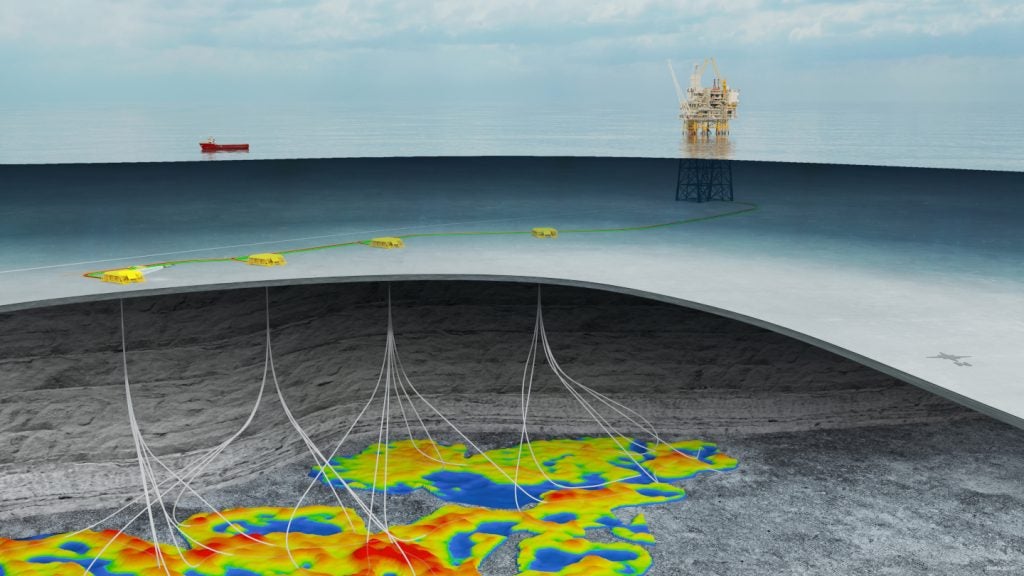

MacCulloch was developed using three development wells at first oil.

Development strategy

The MacCulloch subsea production wells are individually tied back to an FPSO using seabed flexible flowlines and risers.

This marked Conoco’s first use of such a system in British waters.

The development is based on the Dagmar Maersk, a former product carrier which was converted and renamed North Sea Producer.

During the conversion stage, a turret was inserted into the front tanks and a process deck was installed 3.25m above the ship’s main deck.

In addition, processing facilities for 60,000 barrels per day (bpd) of oil were installed.

For enhanced recovery, water-injection facilities with a capacity of 72,000bpd of water and gas lift / export facilities with a capacity of 20 to 24 million cubic feet per day were also specified.

The North Sea Producer has an oil-storage capacity of 560,000bbl and it can carry out offshore loading, in the event that the pipeline becomes unavailable.

The FPSO and all production facilities, including personnel, maintenance and logistical support for the life of the field, are supplied under a production services contract with the North Sea Production Company, a joint venture between Odebrecht-SLP and Maersk.

These services are supplied on a per-barrel tariff arrangement, based on production.

Export

Processed oil is metered on the vessel and transported by pipeline to the Piper B platform, which is operated by Elf Exploration.

This lies 30km to the north-west of MacCulloch, via a 250mm pipeline.

From there, it is taken by another pipeline to the Flotta Oil Terminal in the Orkney Islands.

Meanwhile, associated gas is exported to Piper B. From there is it transmitted using the Frigg pipeline system, to the St Fergus terminal in Aberdeenshire, through a 150mm-diameter, 30km-long line.

The two new pipelines are owned and maintained by Elf Exploration, UK.