The Mittelplate development originally came onstream from a purpose-designed island in 1987. By the end of 2005, a major €150m redevelopment had been implemented resulting in greater production and increased transport capacity. Over 2,700t of oil is now being transported ashore daily.

THE MITTELPLATE CONSORTIUM

The Mittelplate Consortium consists of RWE Dea as the operating company and Wintershall. The field was discovered by well Mittelplate 1, in the Dogger sandstone in 1981 where reserves of 75 million tonnes were confirmed, making it Germany’s largest oil field.

It is situated on the southern edge of Schleswig-Holstein Wadden Sea National Park in ecologically sensitive tidal flats, necessitating environment-friendly offshore production strategies.

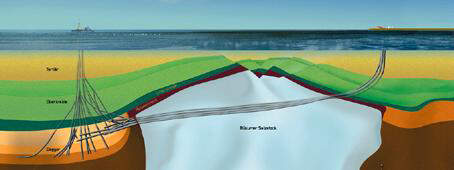

An artificial drilling and production island was built 7km off the coast following detailed hydrographic, hydrodynamic and meteorological studies modelling storm, wave and ice-flow conditions.

Measuring 70m by 95m, the island is protected by 11m-high sheet piling. The reservoir is exploited by 18 wells (slots for 44 wells) – some horizontal or deviated – of up to 3,000m, tapping the oil-bearing sandstone layers to develop the huge western section of the oil field. Oil export used double-hull barges, 45m long, 18m wide and with a fully-laden draught of 2m.

MITTELPLATE REDEVELOPMENT

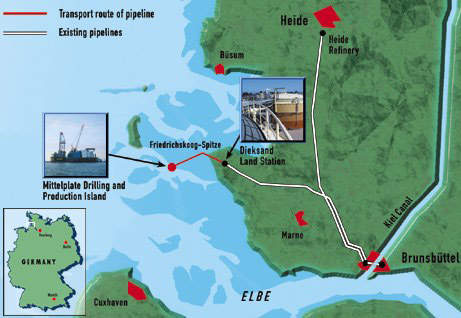

A major part of the redevelopment is the construction of a land-based facility at Dieksand, from which 2,000m to 3,000m-long extended-reach production wells could tap into the eastern part of the deposit.

The programme included a pilot well and seven high-tech extended-reach wells with 7,727m, 8,284m, 8,367m, 8,995m, 9,275m, 8,450m and 8,672m outreaches, including a 4km section cutting straight through the Büsum salt diapir. This integrated offshore and onshore development has contributed to the more rapid exploitation of the oil field.

THE PIPELINE

The upgrades to the island’s production facilities made it possible to increase the annual production volume from the initial 250,000t of crude to nearer 900,000t, however tidal and meteorological factors restricted transportation capacity, effectively reaching the island’s production limit.

Two 7.5km stainless steel pipelines were therefore laid from Friedrichskoog-Spitze through the mudflats off the coast and on through the Marner Plate to Mittelplate Island.

On the landside of the dike, the pipeline followed a 2.8km course to the Dieksand Land Station. One pipeline carries the increased volume of crude from the island while the other serves as a return line for the reservoir water extracted during crude oil processing.

This second pipeline makes it possible to reinject the reservoir water from the Mittelplate Island into the lower section of the oil reservoir in an ecologically neutral process.

The subsea pipelines covering the entire offshore distance were laid in six sections by means of horizontal drilling. These pipeline sections were pre-assembled both on land and on a pontoon moored at Mittelplate Island before being dragged into place for installation.

This required the construction of a system consisting of pylons with supporting roller bearings for transporting the pipeline sections. The pipeline sections were pulled into two separate small-volume boreholes running parallel. On land, the stainless steel pipelines were laid into open trenches.

MITTELPLATE ISLAND LIVING QUARTERS

The redevelopment included new living quarters including staff facilities, resulting in the accommodation rising from 69 to 96 people. New facilities included:

- 48 double cabins

- Offices and meeting rooms

- Sanitary facilities and changing rooms

- Mess and kitchen facilities

- Medical treatment room

- Social facilities such as common rooms, recreation rooms plus rooms for leisure activities

- Supply and disposal systems (technical construction equipment, electricity supply)

- Safety systems (escape routes, fire prevention, emergency muster room)

A new drilling rig was also specified. This was won by Bentec GmbH Drilling & Oilfield Systems from Bad Bentheim. The contract was worth just under €38m.

Reserves have now been put at over 100 million mt of crude oil with estimates of commercially recoverable reserves totalling around 40 million mt.