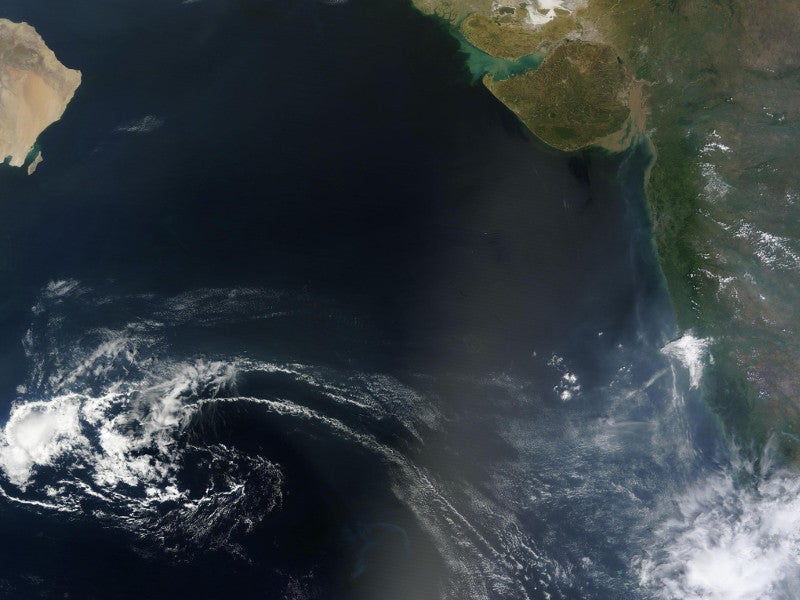

The Mumbai high field (previously Bombay High field) lies in the Arabian Sea offshore the western coast of India. It was discovered in 1974 and commenced production in 1976.

The field is operated by the Oil and Natural Gas Corporation (ONGC), an oil and gas company based in India.

The oil field consists of two blocks named Mumbai High North (MHN) and Mumbai High South (MHS). The blocks were divided based on the shale barrier, assisting in the independent exploitation of reserves at both sites.

ONGC’s board granted approval for the second phase of the MHN redevelopment project in January 2009, followed by the third phase in June 2014. Phase four of the redevelopment project was approved in February 2019 and is currently in progress.

Mumbai High field also includes the development of the Cluster 8 marginal field discovered in 2018. The Cluster 8 field commenced production in April 2022 and added 43 million tonnes (Mt) of oil and 0.464 billion cubic metres (bcm) of gas to the Mumbai High field’s production. It was implemented at a cost of Rs22.92bn ($301m).

Mumbai High field discovery details

Mumbai High field was discovered in February 1974 by the Russian and Indian team from the seismic exploration vessel Academic Arkhangelsky while mapping the Gulf of Cambay between 1964 and 1967.

The discovery of Mumbai High field and subsequent other discoveries in the western offshore area changed the oil industry in India.

In 2018, a major oil discovery was made from well WO-24-3, which indicated a potential of approximately 29.74 million tonnes of oil equivalent (Mtoe) in the area.

Geology and oil reserves at Mumbai High field

Different oil and gas reservoirs, such as L-I, L-II, L-III, L-IV, L-V, basal clastics and fractured basement from top to bottom, are present in Mumbai High field. L-II and LIII are primarily limestone oil reservoirs dating from the Miocene age, further classified into several layers.

Mumbai High field has approximately 1,659Mt of total reserves in place.

Mumbai High field development details

ONGC announced its plan for the redevelopment of Mumbai High field in 2000. It planned to spend approximately Rs90bn ($200m) in five years for the project. The plan was divided into two phases. The first phase started in 2000 and was completed in December 2006.

Phase one is expected to yield an additional crude oil production capability of 23.25Mt and 6.1bcm of gas by 2030 from 73 new wells and ten sidetrack wells.

The cumulative oil production from phase one redevelopment wells was 9.34Mt and cumulative gas production was 2.89bcm until March 2008.

Mumbai High field reached its peak production rate of 400,000 barrels of oil per day (bopd) in 1985 and continued at the same rate until 1989.

A decline in oil and gas production led to the need for a redevelopment plan. Production declined gradually, sinking to 220,000bopd and ten million standard cubic metres of gas per day (Mscmd) in 2001.

ONGC invested approximately Rs80bn ($178.4m) during phase one for better efficiency and controlling the decline in oil and gas production. During phase one, 29% of the 1,659Mt of total reserves were improved.

Mumbai High North phase two redevelopment details

Phase two redevelopment, announced in 2009, will result in additional crude oil production of 17.354Mt and 2.987bcm of natural gas, totalling 20.34Mt of oil equivalent by March 2030.

Phase two of the MHN redevelopment plan aimed to further enhance the recovery rate from Mumbai High field by drilling 73 new wells and side-tracking 38 poor producers. Small reservoirs such as L-II and L-I were combined with major reservoir L-III to strengthen its oil production and development programme. Phase two was estimated to cost approximately Rs71.33bn ($153.43m).

Mumbai High North phase three redevelopment details

ONGC approved phase three of redevelopment for MHN in June 2014. Phase three redevelopment is expected to add 6.997Mt of crude oil and 5.253bcm of gas capabilities by 2030.

It involved the installation of five wellhead platforms, modifications at 13 platforms, one clamp-off facility for wells at an existing platform, and the construction of associated pipelines. It also involved the drilling of 52 new wells and 24 side-track wells.

Phase three redevelopment was completed in 2017 with an estimated investment of approximately Rs58.13bn ($955m).

Mumbai High North phase four redevelopment details

Phase four involves the drilling of 43 wells, which was completed in December 2022, and the installation of a new offshore platform, which was completed in February 2023.

Phase four development is expected to be commissioned by December 2023. It involves an estimated investment of Rs39.76bn ($484.52m).

Mumbai High South phase three redevelopment details

MHS phase three redevelopment is also in progress with an estimated investment of Rs60.68bn ($855.77m).

The project will increase production by 7.547Mt of oil and 3.864bcm of gas by 2030. The redevelopment project involves the drilling of 70 new wells.

Mumbai High South phase four redevelopment details

The MHS phase four will upgrade the ageing water injection facility at the field and install a new water injection (NWIS-R) platform.

The NWIS-R will be an eight-legged platform with topsides weighing 10,000t. It is designed to process raw seawater and inject it back into the reservoir for enhanced oil recovery (EOR).

The installation of the topsides and jacket of the NWIS-R was completed in May 2021.

Mumbai High field infrastructure details

ONGC began construction of the new process complex for MHN near the old Bombay High North (BHN) platform in 2007. The platform was completely destroyed in a major fire in July 2005, which affected oil production. Along with the field’s redevelopment plan, the new MHN complex was also developed to have a handling capacity of approximately 270,000 barrels of liquid and 6.9Mscdm of compressed gas, as well as an oil pumping capacity of 50,000 barrels a day.

The MHN process complex consists of a process-cum-riser platform, living quarters, a subsea-connected flare structure, subsea pipelines and adjoining topside modifications, such as facilities for handling sour gas from B series marginal fields. The new MHN complex ensures optimised and safe operations in the field.

The new MHN process platforms organise the gas lift pipelines and oil export lines of the MHN field. The former BHN platform was replaced with a new MHN process platform that created additional facilities for gas processing from future platforms.

To facilitate the interconnectivity of the power generating system, a high-voltage submarine composite electrical cable was installed in 2007. The installation was completed in 2012.

The installation involved laying submarine electrical cable to interconnect 26 wellhead platforms, electrical submersible pumps (ESP), 81 wells, and associated surfaces. The ESP assists in oil production from high-water cut (90-95%) wells in Mumbai High field.

The board of the company approved a proposal for an investment of Rs39.9bn ($101.3m) in the C series development project in 2007. The investment would facilitate MHN to handle an additional 3Mscmd of gas from C series wells.

Pipelines

ONGC approved the construction of seven pipelines with risers and associated top-side facilities in MHN in April 2007. These pipelines are vital for maintaining optimum efficiency from Mumbai High.

Production from Mumbai High Field

Mumbai High Field reached its peak production level in 1998 with 20Mt a year. Along with its adjoining fields, it produced at a rate of 12.8Mscmd of gas prior to the recent redevelopment projects. The production was approximately 265,000bopd with an average of 63% of water cut and an average production of 1,200 barrels of liquid a well during 2007.

The cumulative production of crude oil, including oil generated as a result of phase one development, was 140.25Mt until January 2009.

The field is operated using the gas lifts method, which is a major artificial lift system used for oil production. Several gas compressors are spread over a number of process complexes in the field to support the broad gas lift network.

As of 2018, the average daily crude oil production at Mumbai High field was 16.9Mt and gas production was approximately 52.32Mscmd.

Contractors involved

Shelf Drilling, an offshore drilling contractor was awarded a three-year contract for the Trident II jack-up rig for operating over the Mumbai High field in January 2023. The Trident II is a three-legged jack-up rig and it was last upgraded in 1985. The rig can operate in a maximum water depth of 300ft to a drilling depth of 21,000ft and can accommodate 130 people.

The contract for the implementation of NWIS-R was given to Larsen & Toubro Energy Hydrocarbon (LTEH), a subsidiary of Larsen & Toubro, a diversified company based in India.

LTEH and ONGC awarded a contract to SEAMEC, a part of MMG Group, for a pre-engineering survey and offshore execution with DPII Seamec Princess diving support vessel in April 2022.

A contract for phase three of the redevelopment was awarded to L&T in September 2014.

SapuraKencana Petroleum, a subsidiary of Kencana HL, was awarded a $273m contract for phase three development work in July 2015. It subcontracted OHCS India and Param Offshore Services for topside hook-up, modification and the pre-commissioning of nine wellheads and a process platform.

L&T secured a $1.18bn contract from ONGC in August 2009. The contract included an order for the MHN processing platform and living quarter projects, along with additional order for the supply of three process gas compression modules, also to be installed in MHN complex. The three compression modules constitute a total of 80,000t of structures. The work included surveying, engineering, procurement, fabrication, installation and commissioning of the facilities by L&T.

Swastik Offshore Services, an offshore construction and catering crew provider, Posh Subsea, a marine services provider, Nautec, an engineering solutions provider, and H2Offshore Engineering, an engineering company, are some of the other contractors involved in the project.