Ram Powell lies in the Viosca Knoll area in the Gulf of Mexico, approximately 125 miles south-east of New Orleans and around 80 miles south of Mobile, Alabama, in water depths ranging from 2,000ft to 4,000ft.

The Ram Powell Unit, approved by the Minerals Management Service in June 1989, encompasses eight Viosca Knoll blocks: 867, 868, 911, 912, 913, 955, 956 and 957.

Drilling

The discovery well was drilled on Viosca Knoll block 912 in May 1985, using the drillship Discoverer Seven Seas.

Between 1985 and 1989, Shell, Amoco and Exxon drilled 12 exploratory wells from five locations and carried out one production test.

Reserves

Five potentially commercial pay sands were logged between 5,500ft and 13,500ft subsea.

Estimated gross recovery from the planned development is about 250 million barrels of oil equivalent, with a 50:50 oil/gas ratio. The API gravity is 33°.

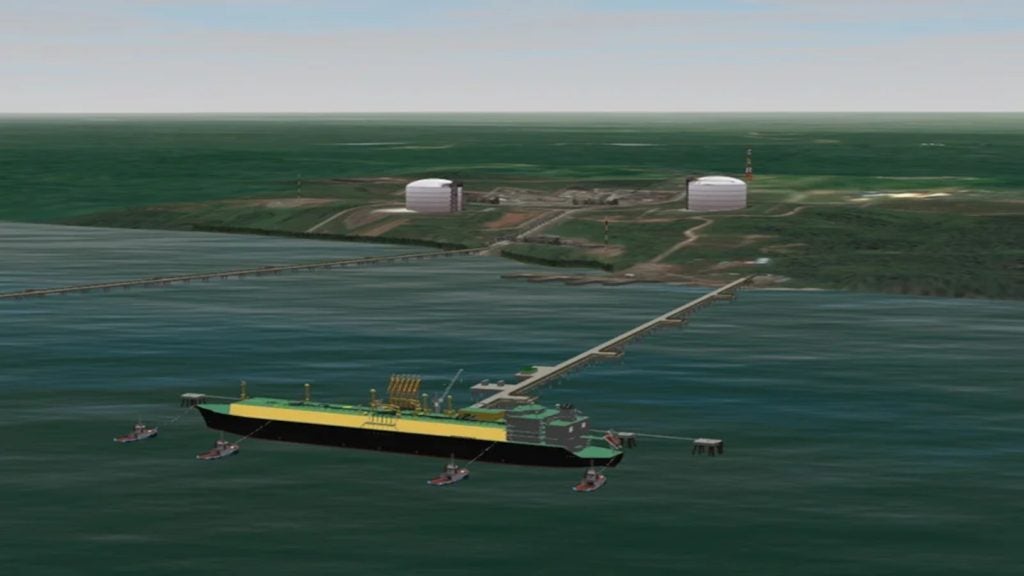

Ram Powell TLP

Completely assembled, the Ram Powell TLP is 3,570ft-high from the seafloor to the crown block of the drilling rig.

It was designed and engineered by a joint partner team made up of personnel from Shell, Amoco and Exxon, with support from outside contractors in Louisiana and Texas. It was designed to simultaneously withstand hurricane-force waves.

Hull

The contract for the hull fabrication was won by Belleli SpA in Taranto, Italy. It was completed in October 1996 and the structure arrived at Aker Gulf Marine’s Ingleside yard, in Texas, in November 1996.

The hull is comprised of four circular steel columns, 66.5ft in diameter and 165ft-high. These are connected by a ring pontoon structure, 27ft-wide and 24.5ft-high, with a rectangular cross section. The hull weighs approximately 15,000t.

Deck

The contract for the modular deck was won by McDermott International and it was built at Morgan City, Louisiana. The first module was loaded out on 6 November 1996 with shipment of the remaining modules concluded by the end of December 1996.

The deck is an open truss / deep girder design. It measures 245ft x 245ft and stands 40ft-high. The structure weighs approximately 8,100t and is composed of five modules, namely: wellbay, quarters, process, power and drilling.

The accommodation module houses up to 110 people, along with a control room and an emergency-response centre.

Tendons / piles

The TLP is secured by 12 tendons, three per corner, each with a diameter of 28in and a wall thickness of 1.2in. Each tendon is approximately 3,145ft-long and the total weight for the 12 tendons is approximately 10,000t.

The tendons will be attached by the TLP foundation system, comprising tendon receptacles held in place by 12 piles. The piles are 84in in diameter and 349ft-long, weighing approximately 270t each.

Aker Gulf Marine fabricated the tendons and piles in Corpus Christi, Texas.

Drilling

The well layout on the seafloor is arranged in a rectangular pattern approximately 60ft x 80ft. The drilling programme envisaged pre-drilling four development wells from the 20-slot template.

The TLP supports a single modified API Helmlich & Payne platform-type drilling rig (leased), equipped with a surface BOP and a high-pressure drilling riser.

Production

The Ram Powell TLP contains complete separation, dehydration and treatment facilities designed to process the oil, condensate and gas.

Estimated ultimate recovery from the development is about 250 million barrels of oil equivalent.

Export

Ram Powell’s oil and gas is piped to platforms in shallow water. Production from the platform is transported approximately 25 miles via a 12in-diameter oil pipeline to Main Pass 289C and a 14in gas pipeline to Viosca Knoll 817.

Both pipelines are installed as part of the Ram-Powell development. Allseas laid the pipelines using the Lorelay.