The Prelude floating liquefied natural gas (FLNG) project marks the deployment of Shell’s FLNG technology for the first time. The project included the construction of an FLNG facility, which is being used to develop Shell’s Prelude and Concerto gas fields, situated in the Browse Basin, offshore Western Australia.

The Prelude and Concerto fields lie in the WA-371-P permit, at water depths of 250m. First gas was achieved in December 2018. A total of $5bn was invested in the project.

The project was previously 100% owned by Shell. INPEX and Korea Gas Corporation acquired 17.5% and 10% stakes in the project in 2012, while CPC Corporation holds a 5% stake in the project. The remaining 67.5% is still owned by Shell.

The Prelude project was approved by the Australian Government in November 2010. Shell made its final investment decision on the project in May 2011 and construction began in 2012.

Prelude discoveries

The Prelude field was discovered by the Prelude-1 exploration well in 2007. The Concerto field was discovered in March 2009 by the Concerto-1 well.

Combined reserves at the Prelude and Concerto gas fields are estimated at three trillion cubic feet.

Natural gas field development

Development drilling at the fields began in 2013 and the first well was realised in December 2014.

Approximately eight production wells were drilled for the floating LNG facility. Installation of two Christmas trees was completed in late 2014 and The FLNG facility arrived in Australian waters in July 2017.

Developing these fields through conventional methods was considered uneconomical due to their small size and remote location, so FLNG technology was used.

The prelude floating LNG facility has a production capacity of 5.3 million tonnes a year (Mt/y) of liquids and condensate, including 3.6Mt/y of LNG, 1.3Mt/y of condensate and 400,000t/y of liquefied petroleum gas.

Field infrastructure includes six LNG storage tanks with a total capacity of 220,000m³. The Upstream facilities include seven wells, four flowlines, six umbilicals and 14 flexible risers.

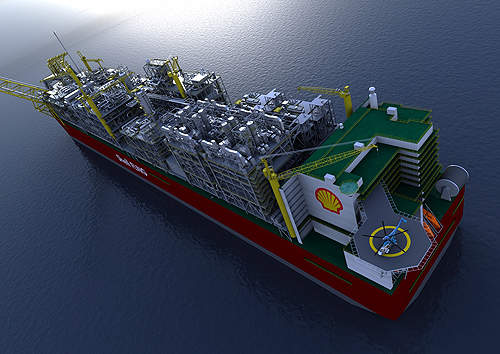

FLNG facility

The Prelude FLNG facility features a double-hulled steel body. It is 488m-long, 74m-wide and weighs approximately 600,000t. It comprises 0.26t of steel with a deck area longer than four football fields, making it the biggest facility worldwide. It features gas receiving and processing facilities, control rooms, accommodation and storage facilities.

The design of the FLNG facility enables it to withstand extreme weather conditions, including a category 5 cyclone. It is permanently moored at a distance of 200km offshore at the Prelude field at a depth of 250m. It will be moored for 25 years using four groups of mooring chains. Each mooring chain is connected to the seabed by suction piles.

Gas is treated at the FLNG facility and liquefied to -162°C. The liquefied gas and other products are then be offloaded onto LNG carriers for distribution to markets worldwide.

FLNG technology is considered an important milestone for the LNG industry as it reduces the cost of developing LNG projects. It assists in eliminating the need for laying pipelines for gas transport, construction of onshore LNG processing facilities, dredging and other related works.

Natural gas resources previously considered uneconomical and located too far from the shore can now be developed using Shell’s technology.

The technology also provides environmental benefits as it uses less seabed area and eliminates the need for carrying out underwater and near shore works.

Contracts for the Prelude project

The design, manufacture and commissioning of the Prelude facility was carried out by a consortium of Technip and Samsung Heavy Industries under a contract awarded in July 2009.

The contractual scope included design and construction of several FLNG facilities over a 15-year period. The Prelude FLNG facility was constructed at the Samsung shipyard in South Korea.

In July 2010, the consortium selected Emerson as the automation contractor for the project. The contract required Emerson to design and deliver control and monitoring technologies for the facility.

Shell contracted FMC Technologies in June 2011 to supply subsea equipment for the project. The contract included production trees and manifolds, risers and control systems.

The contract also included an aftermarket agreement under which FMC rendered installation and commissioning services. Orders associated with the aftermarket deal were awarded in late 2011.

SBM Offshore was contracted by Technip in June 2011 to engineer, procure, build and install a turret mooring system for the FLNG facility.

Related project

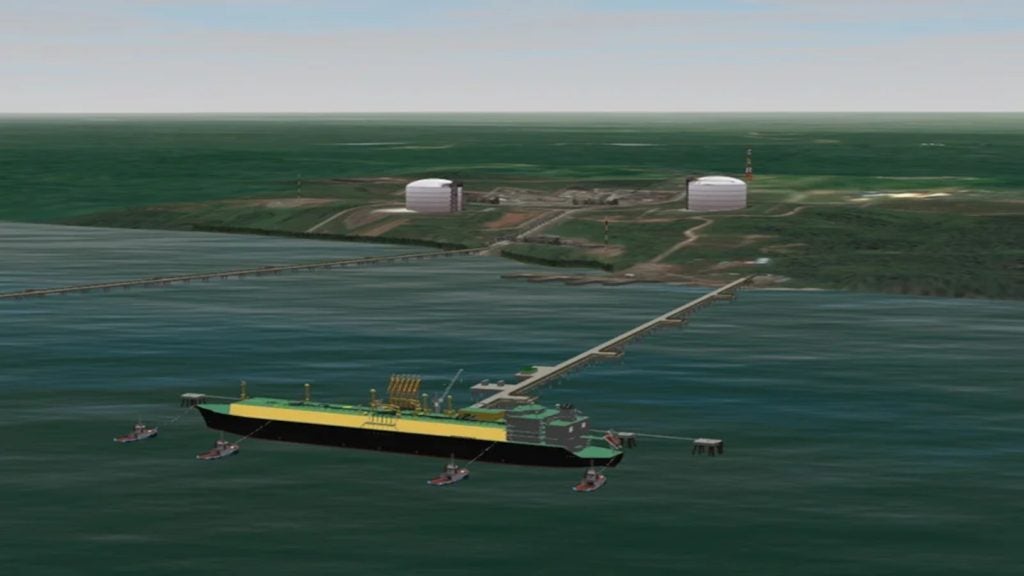

Bonaparte LNG Project, Timor Sea, Australia

The Bonaparte Liquefied Natural Gas (LNG) project covers the deployment of a floating, production, storage and offloading (FPSO) LNG facility in the Bonaparte Basin in the Timor Sea, off the northern coast of Australia.

In June 2011, Shell contracted Air Products to supply its LNG heat exchanger.

GE Oil & Gas was contracted by Technip in September 2011 to provide two steam turbine driven compressors. The contract also involved commissioning and two years of training, operation and supply of spare components.

Technip awarded a contract to Kawasaki Heavy Industries in September 2011 to provide seven boiler units for installation on the FLNG facility. The boilers are being used to generate power and process LNG.

Mitsubishi Heavy Industries Compressor Corporation (MCO) was contracted to supply three compressor trains and a power generation system in January 2012.

In May 2012, Technip France awarded a contract to FMC Technologies to receive offshore loading arm systems for the project. FMC’s Loading Systems business in Sens, France, is the designer and manufacturer of the equipment.

Shell awarded the subsea installation contract for the Prelude LNG project to Technip in June 2012. The scope of the contract mainly included project management and fabrication services.

Wood Group received a $10m contract to provide a computerised maintenance management system for the FLNG project in August 2012.

Decmil Australia, a subsidiary of Decmil Group, secured a $25m contract to design and construct Darwin Onshore Supply Base for the LNG Facility in March 2013.

In January 2014, Emerson Network Power (now Vertiv) was contracted to supply the main uninterruptible power supply (UPS) systems.

KT Maritime Services Australia, a subsidiary of KT Maritime, secured a contract from Shell in February 2014 to supply three infield support vessels (ISVs).

Civmec was contracted by Technip in August 2014 for the supply, fabrication and testing of subsea components for the Prelude development.

In April 2015, ASCO Group secured a logistics and supply base management contract for Shell’s FLNG facility.

In November 2015, Monadelphous was contracted to provide maintenance, brownfield modifications and turnaround services worth $200m.

Atkins was contracted to develop asset integrity models for future inspection and maintenance at the Prelude FLNG offshore facility, in November 2015.

POSH Terasea was contracted to provide towage and positioning services in January 2016.

In January 2016, Shell placed a contract with Wood Group for specialist consultancy services for the Prelude FLNG project.

In March 2016, ABB received a five-year contract to deliver equipment and services to the FLNG facility. The scope of contract included supply of motors, generators, variable speed drives and low-voltage switchgear, as well as lifecycle management of the electrical equipment.

MRC Global Australia, a subsidiary of MRC Global, was contracted to provide maintenance, repair and operations (MRO) requirements for the FLNG project.

DOF Subsea secured a five-year contract to provide a full-time underwater services and multipurpose supply vessel (MPSV).

Emerson was contracted to deliver automation maintenance and reliability services for the Prelude FLNG project, in September 2016.