Vixen is wholly located in block 49/17a, licence P033 in the southern North Sea, approximately 135km (84 miles) off the Lincolnshire coast in the UK.

The operator Conoco and the co-venturer BP each hold a 50% interest in the field.

Discovery

The Vixen field was originally known as E-Plus. It was discovered by well 49/17a-13, which was drilled and temporarily suspended in May 1999 by the jack-up drilling rig Glomar Adriatic VI.

The well was drilled at a water depth of 33m (109ft).

Vixen lies between two of the most prolific fields in the area, Viking E and Victor. Its reservoir is located in Rotliegendes sandstone, approximately 2,844m (9,385ft) subsea.

Conoco reservoir engineers have estimated a projected field life of six years.

However, studies indicate that with optimal reservoir management and development, the field has the potential to yield significantly more natural gas than this, over a lifespan that could be considerably longer.

Production

Vixen contains 117 billion standard cubic feet of proved natural gas reserves, including 58.5 billion cubic feet (bcf) net to Conoco.

The planned flow rates for the field have been put at 140 million standard cubic feet of natural gas per day, approximately 16% higher than the original design rate.

Vixen natural gas is produced from a single subsea well. The development is based on re-entering the original discovery well 49/17-13 and completing a 49° sidetrack through the reservoir.

The production re-entry well was drilled by the jack-up drilling rig Ensco 80. The jack-up was also used to install the subsea architecture.

The produced natural gas is transported 8.6km (5 miles) via a 10in subsea pipeline to the BD platform in the Viking B central complex.

This has been modified to handle Vixen’s output. There is also an umbilical installed for methanol supply, hydraulics power and communications.

Modifications

The modifications to the Viking platform include the installation of a new 10in production riser, a J tube for the umbilical, new methanol pumps, the installation of subsea control and hydraulic packages, and metering and topside control for tie-in to the production separator.

Halliburton and Brown & Root, along with AMEC and DNV, were responsible for all elements of these host platform modifications through an SNS alliance contract.

From Viking, gas is sent 130km (80 miles) through the Viking Transportation System (VTS) subsea pipeline, to the Conoco-operated Theddlethorpe Gas Terminal on the coast of Lincolnshire, from where production operations are remotely controlled.

Construction

Creating and installing the subsea elements of the Vixen development involved the services of several manufacturers, suppliers and contractors.

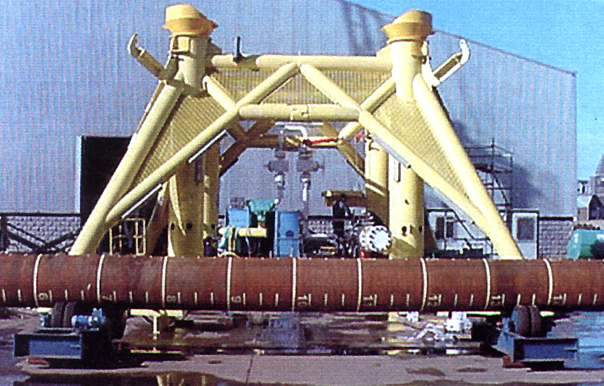

Dril-Quip won the contract to fabricate and supply both the subsea tree and its 65t wellhead protection structure (WHPS). With a 15-year life, this structure has overall dimensions of 114m x 114m and stands 6.25m-high.

It is anchored by four piles, which are 762mm in diameter and 24m-long, weighing 11.1t each.

Kvaerner Oilfield Products designed and manufactured the Vixen control system upgrade at Theddlethorpe, and Coflexip Stena Offshore (CSO) was responsible for the design, supply, installation, testing and pre-commissioning of the gas-export pipeline, the umbilical, and the installation of the wellhead protective structure.

The CSO Wellservicer loaded out the WHPS and installed it around the existing 30in conductor. The structure was then piled, using a 200t hammer and the top-latch mechanism was locked.

The Ensco 80 arrived in mid-2000 to drill the side-track and complete the well operation that included installing and testing the tree.

The Apache was then used to install the pipeline and test / pre-commission the project.

Final development costs were put at £24m ($36m), which were below the original budget by 11%.