The Veslefrikk field is located at a depth of 607ft in block 30 / 3 of the northern part of the North Sea. The field was discovered in 1981 and lies about 30km north of Oseberg, Norway.

Statoil is the operator of the field, with an 18% interest. Other partners include Petoro with 37%, Talisman Resources with 27%, RWE Dea with 13.5% and Revus Energy with 4.50%.

Veslefrikk reserves

The Jurassic Veslefrikk reservoir is located at depths ranging between 2,800m and 3,200m. The field reservoir is made of the Brent and Dunlin Groups and the Statfjord formations.

The field’s main reservoir is of the Brent Group formation, which contains 80% of the reserves.

The field is estimated to contain 36.4 million barrels of oil and 141bcf of gas.

Veslefrikk field development

Statoil declared the Veslefrikk field commercial in 1986 and commenced detailed engineering in October 1987. The plan for development and operations (PDO) of the field was approved in 1987. The field came onstream in 1989 and achieved peak production in 1990.

Statoil drilled 14 production wells, five water alternate gas injection wells, four water injection wells and one gas injection well. All the wells are tied back to the Veslfefrikk A fixed platform, which is connected through a bridge to the Veslefrikk B semisubmersible facility.

As per the original PDO, development at the Veslefrikk field was to end in 2009. The field, however, still holds large amount of recoverable oil and gas. Recoverable reserves at the end of 2008 were estimated at 6.3m standard cubic metres of oil and 1.6m standard cubic metres of gas.

Statoil submitted an application to the Petroleum Safety Authority of Norway (PSA) to continue development of the field. In September 2009, the PSA granted approval to Statoil to use the Veslefrikk facilities until 2020.

Veslefrikk A platform

Veslefrikk A is a fixed steel wellhead platform with drilling capabilities. The platform contains 24 well slots and can drill up to a depth of 20,000ft.

Gas and liquid from the platform are transported to Veslefrikk B platform through 150m flexible hoses with an 8in internal diameter.

Veslefrikk B platform

The Veslefrikk B platform is a semisubmersible floating production vessel with a capacity to produce 30,000 barrels per day.

It was converted from the West Vision drilling platform in Stavanger between 1988 and 1989. The drilling platform was originally built in South Korea.

Exports

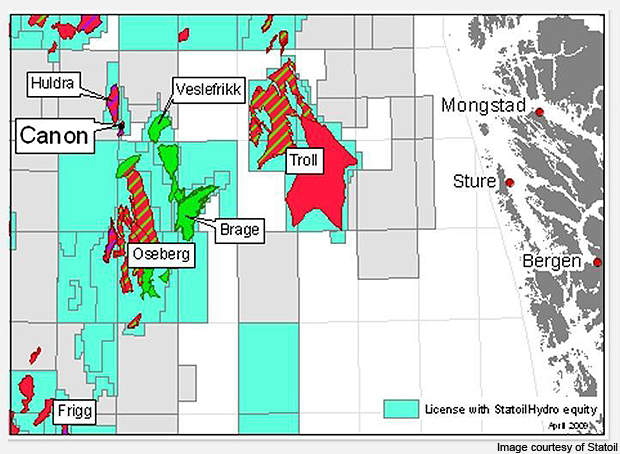

After initial processing at the Veslefrikk B facility, oil is transported to the Oseberg field. From here it is transported through a pipeline to the Sture terminal near Bergen.

Gas produced at the field is transported via the Statpipe system through Karsto to Emden in Germany.

Contracts

In January 2011 Statoil awarded an Nkr160m EPC contract to Odfjell Drilling to replace the drilling system of Veslefrikk platform with a new upgraded drilling control centre. Odfjell will work in cooperation with Aibel on the project.

Fabricom and RDS, a subsidiary of KCA Deutag, were contracted by Statoil in 2009 to conduct a conceptual engineering study for modification of the Veslefrikk A platform. The study was undertaken to extend the life of the platform.

In May 2009, Aker Solutions won a contract to supply mechanical wireline services for the Veslefrikk field.

Aibel was awarded a $45m contract in 2007 to upgrade the water re-injection system of the Veslefrikk B platform.

Aibel subcontracted M-I EPCON to supply a water treatment package for the Veslefrikk B platform.

The package consisted of two trains with a design rate of 95,000bpd, 625m³ per hour. It also included a 9,500bpd, 63m³ per hour reject skid.

VTT Maritime carried out re-certification of six anchor chain lines at the Veslefrikk field in 2006.

NKT Flexibles was awarded a contract to supply four 8in ID flexible risers for the field. These double-catenary, dynamic risers were used for oil production and export, gas and water injection, and gas export. These risers linked the Veslefrikk A jacket to the Veslefrikk B platform.

Mercur Maritime and Ingenium supplied a mud return gutter for the Veslefrikk A platform.