The Egina oil field is located approximately 150km off the coast of Nigeria in Gulf of Guinea, at a water depth of approximately 1,600m.

The partners in the field development include Total Upstream Nigeria (24%), CNOOC E&P Nigeria (45%), Sapetro (15%) and Petrobras Oil and Gas (16%). Egina is the third deepwater offshore development of Total in Nigeria.

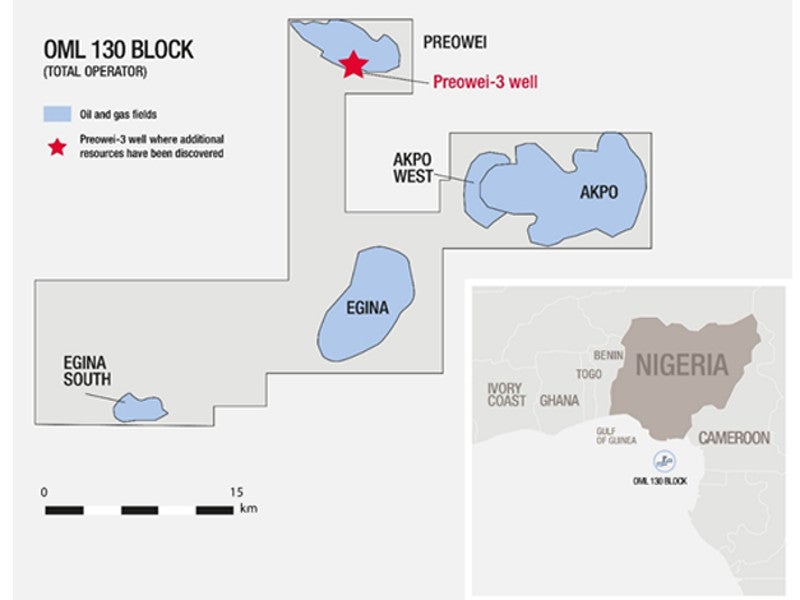

Located approximately 20km away from Akpo field, Egina field lies within the oil mining lease block (OML) 130 and covers an area of around 500 square miles.

The construction work for the $16bn oilfield development project began in December 2013, after receiving the construction approval from Nigeria National Petroleum (NNPC). The field achieved its first oil in December 2018 and is expected to produce 200,000 barrels of oil a day at a peak production rate.

Discovery of the Egina oil field

In December 2003, the oil field was discovered by drilling of Egina-1 well, which was followed by drilling of the appraisal well Egina-2 in October 2004.

The appraisal programme and seismic data processing resulted in the Egina-3 well drilling in September 2006, which occurred at a water depth of approximately 1,500m. Egina-4 was drilled in November 2006 and Egina-5 was drilled in January 2007. The Egina-5 well is producing 12,000 barrels of oil a day.

The five wells on Egina field were encountered between 60m and 80m of oil in Miocene sands. The oil reserves are estimated at 550 million barrels. The light oil is rated at 28° API.

Egina field development

The Egina field was initially planned to be developed as a subsea tieback to the Akpo floating production storage and offloading vessel (FPSO). Major discoveries in the area, however, lead to the standalone development of Egina.

Basic engineering studies of the field began in 2008. The National Petroleum Investment Management Services (NAPIMS) granted approval for the project in 2008 while final approval from the Nigerian authorities was received in 2009.

Egina field infrastructures

The Egina project includes the production of oil from 44 subsea oil wells, drilled by West Jupiter drillship. The wells are connected to an FPSO unit via a subsea production system.

The subsea production system comprises risers, 52km of oil and water injection flowlines, 12 flexible jumpers, 20km of gas export pipelines, 80km of umbilicals and subsea manifolds.

The FPSO measures approximately 330m in length, 61m in width and 33.5m in depth, and has an oil storage capacity of approximately 2.3 million barrels. The FPSO has topsides modules with a gross dry weight of 47,500t. It is also equipped with a 100m high flareboom and has accommodation capacity of 200 individuals at a time. The production capacity of the FPSO is 208,000 barrels a day.

The project is also integrated with an oil offloading terminal.

Contracts involved

In July 2009, Total awarded a front end engineering design (FEED) contract to Dover Engineering. Dover signed an agreement with J P Kenny and MCS Kenny to facilitate project delivery.

The first comprehensive FEED, carried out by J P Kenny and MCS Kenny, was completed in July 2010.

The contract provided the scope for the comprehensive design studies and engineering assessments, development of specifications, documentation and technology studies, as well as the design of the umbilicals, flowlines, risers and the subsea production systems used in the field development.

In 2008, Total signed a major contract with Abbott Risk Consulting (ARC) for safety engineering design studies on the Egina FPSO project. According to the contract, ARC was responsible for conducting fire risk analysis, explosion modelling, gas dispersion modelling and quantitative risk assessment. ARC also carried out a range of other studies to conclude a number of design options.

Saipem received a $3bn engineering, procurement, fabrication and installation (EPCI) and pre-commissioning contract for the project in June 2013. In the same year, FMC Technologies was awarded a $1.2bn engineering, procurement, construction and commissioning (EPCC) contract in the same year to provide subsea production systems for the project.

In July 2013, TUNIP awarded the project management, engineering and manufacturing contract to DUCO, a subsidiary of Technip, for providing the steel tubes umbilicals for the Egina project.

Technip FMC was also awarded the EPCI contract worth $1.2bn for the subsea production system of the Egina development project in 2013.

In January 2014, FMC Technologies subcontracted Aveon Offshore to provide fabrication services for the subsea structures at the field. First steel for the same was cut in December 2013.

Vallourec was contracted to supply premium subsea line pipe for the Egina project in October 2014.

Samsung Heavy Industries (SHI) received a turnkey contract from Total for the Egina FPSO in 2013. The contract included design, procurement, construction, delivery and trial operations.

SHI awarded the subcontract to Vallourec for supplying 1,700t of pipeline segments for the Egima’s FPSO unit.

LADOL Integrated Logistics Enterprise provided the logistics services during the construction of the Egina’s FPSO unit.

Nexans was subcontracted by Samsung Heavy Industries (SHI) to deliver cables for the Egina FPSO project. MTE was contracted by SHI to deliver design, engineering, fabrication services and additional heat shields for the Egina FPSO in February 2016.