China National Petroleum has patented a method for evaluating the downhole working condition of a PDC bit. The method involves indoor testing in different cores to analyze WOB, rotational speed, torque, ROP, and vibration. Real-time data reading and improved prediction models are used for evaluation. GlobalData’s report on China National Petroleum gives a 360-degree view of the company including its patenting strategy. Buy the report here.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

According to GlobalData’s company profile on China National Petroleum, AI assisted CAD was a key innovation area identified from patents. China National Petroleum's grant share as of March 2024 was 71%. Grant share is based on the ratio of number of grants to total number of patents.

Method for evaluating downhole working condition of pdc bit

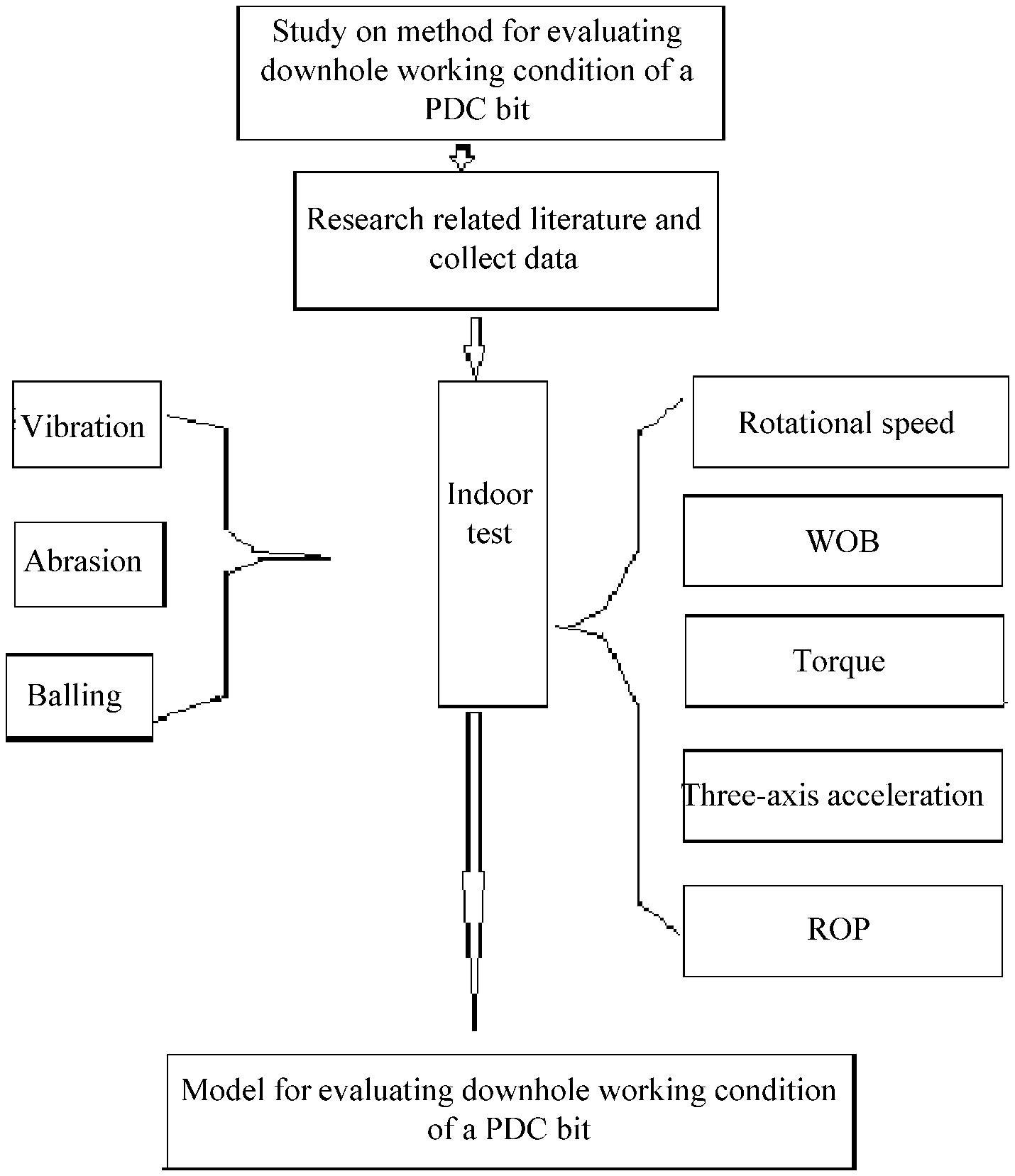

A recently granted patent (Publication Number: US11959375B2) discloses a method for evaluating the downhole working condition of a polycrystalline diamond compact (PDC) bit used in drilling operations. The method involves conducting indoor tests using the PDC bit on different full-sized cores with varying degrees of abrasion and balling under specific weight on bit (WOB) and rotational speed conditions. The data obtained from these tests is then used to enhance an existing prediction model and evaluation method to assess the PDC bit's performance in real-time by monitoring parameters such as WOB, rotational speed, torque, rate of penetration (ROP), and vibration severity. The test setup includes an acceleration acquisition system, a WOB-torque-displacement acquisition system, and a hydraulic system connected to the PDC bit, with the core fixed on a rotary table below the bit.

Furthermore, the method involves processing the data obtained during the indoor tests by intercepting stable WOB, torque, and displacement data to calculate average values, as well as analyzing acceleration data to determine root mean squares and maximum values. The WOB-torque-displacement acquisition system comprises a dynamic strain gauge, a bridge box, and a data acquisition system, while the acceleration acquisition system includes a wireless acceleration transducer, a wireless gateway, and a second data acquisition system. The tests are conducted with the PDC bit and drill pipe nipple stationary, while the core and rotary table rotate at a constant speed, with adjustments made to the WOB and rotational speed at specific intervals during the testing process. The cores used in the tests include limestone, hard sandstone, or soft sandstone to simulate different drilling conditions.

To know more about GlobalData’s detailed insights on China National Petroleum, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.