Halliburton has introduced the SmartWell Turing electro-hydraulic control system, the next generation of the SmartWell intelligent completions technology portfolio, for improved reservoir management.

According to the company, this system “sets a new standard” in reservoir flow control by enhancing recovery while lessening the number of wells required.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The Turing electro-hydraulic control system is engineered to offer quick zonal optimisation.

It incorporates integrated position sensors to enable operators to control well productivity with speed and precision.

The streamlined and flexible design of the solution aims to minimise rig time, operational risk and production delays.

Halliburton Completion Tools vice-president Maxime Coffin said: “As the pioneer of SmartWell intelligent completions, Halliburton’s advancements in this technology strengthen our industry leadership.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“Our new Turing electro-hydraulic control system builds on that legacy. It empowers our customers to improve recovery, manage subsurface uncertainty and achieve lower costs with greater operational efficiency.”

The Turing system, along with the Clariti digital reservoir management suite, offers customers enhanced insights and real-time recommendations for optimising well production and field operations.

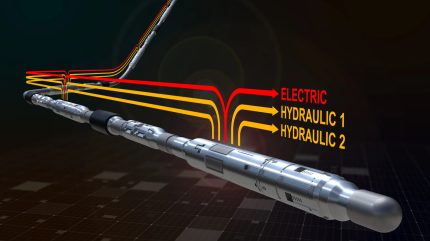

It is capable of managing up to 12 zones with three control lines: two hydraulic and one single-wire tubing-encapsulated conductor (TEC).

This TEC line engages with downhole sensors via the DataSphere permanent monitoring suite, removing the need for extra lines.

In May, Halliburton launched EarthStar 3DX, a 3D horizontal look-ahead resistivity service.

The EarthStar 3DX service is said to feature the industry’s nearest-to-bit, ultra-deep resistivity sensor, which facilitates the early identification of formations.