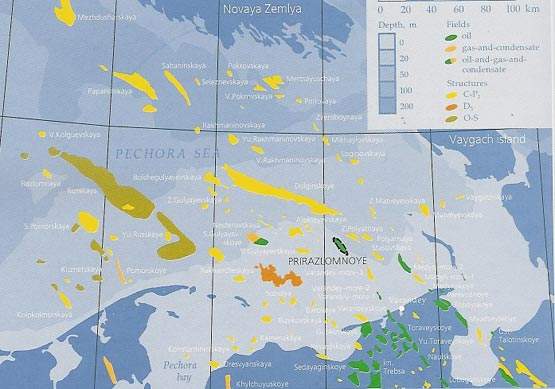

The Prirazlomnoye oilfield is located south of Novaya Zemla in northern Russia on the Pechora sea shelf, at a distance of 60km from the shore. The water depth in this area is 19m to 20m. The field was discovered in 1989. The development license was won by Rossneft in 1993 and transferred to Sevmorneftegaz in 2002.

This industrially underdeveloped area is characterised by extremely low temperatures and strong ice loads. It is ice-free for 110 days a year and the cold period lasts 230 days. Ice thickness is up to 1.7m. The annual average temperature is -4°C and the temperature minimum is -50°C. Wind strengths reach up to 40m/s and wave heights up to 12m.

Prirazlomnoye field reserves and production

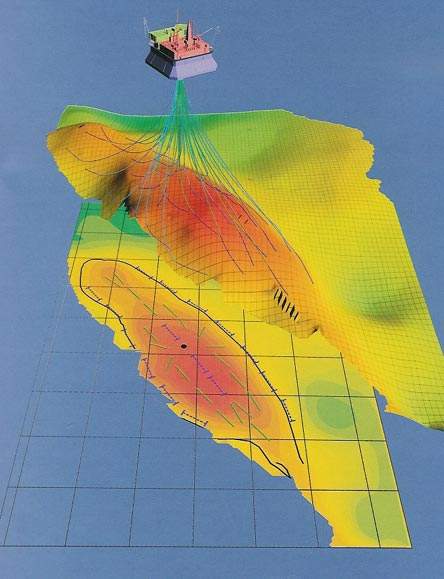

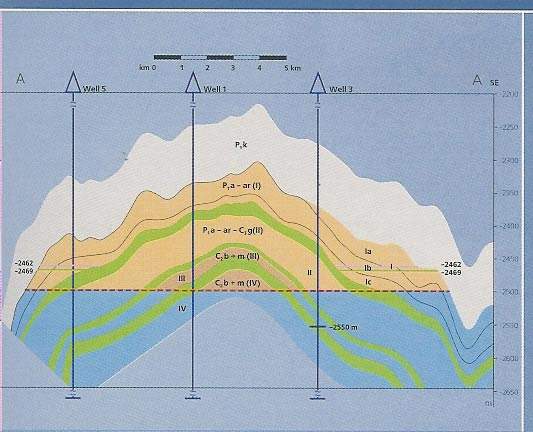

Prirazlomnoye has reserves of 610 million barrels. Drilling plans envisage up to 36 directional wells (19 producing, 16 injection and one absorption). The first production well was launched in December 2013 and ten production wells were commissioned by January 2017.

All wells are being drilled from the single rig on the platform, with simultaneous drilling and production. Perimeter water flooding of horizontal injection wells occurs at near-fracturing injection pressures. This will result in a maximum annual plateau production volume of 7.55 million tons by the fifth year. Production is expected to last for 22 years.

Prirazlomnoye field development details

The field development concept was designed by Vniigaz Institute, a subsidiary of Gazprom. The design envisages operations being carried out from a single stationary platform at the centre of the development.

This offshore fixed gravity platform is the first construction of its kind in Russia.

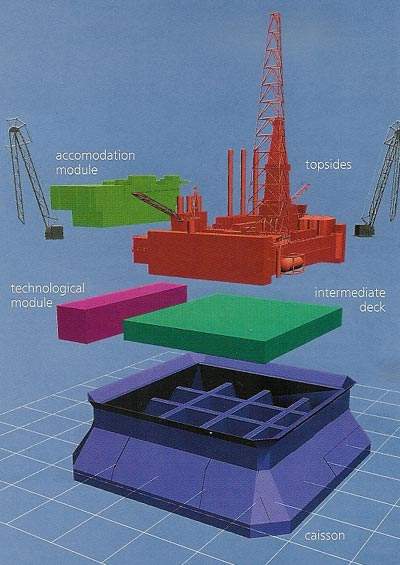

The topsides are based on the former UK North Sea Hutton tension leg platform, bought by Rosneft in 2002 and upgraded for its new work at the FSUE Sevmash military shipyard in Severodvinsk. The new platform, Prirazlomnaya, has a field life of 50 years. Platform costs are approximately $800m.

The topsides were dismantled near Murmansk and towed to Severodvinsk. Meanwhile, the caisson was constructed by Sevmash as a number of caisson superblocks. The yard was also responsible for the offloading complex, platform towing and the accommodation module. Nearby, in the Severodvinsk yard of Zvyozdochka, superblocks 1 and 4 were constructed. The technological module was built in the Vyborg shipyard and other parts of superblocks and piping were built at the Tsentrenergomontazh facilities.

The topsides weigh 39,000t. It has a single derrick and 40 well slots. There are two oil offloading systems with capacities of up to 10,000m³/h. The topsides sit on a 126m², 97,000t caisson. It includes 14 oil storage tanks with a capacity of 113,000m³, as well as two water storage tanks with a total capacity of 28,000m³. The facility has an oil production capacity of 22,000t/d, a daily gas production capacity of one million cubic metres, and injects water at 32,000m³/d.

The superblocks were welded and installed in 2004 followed by the towing and installation the topsides and the concreting. After a period of settling down a safety berm was laid around the field.

Oil export from Prirazlomnoye

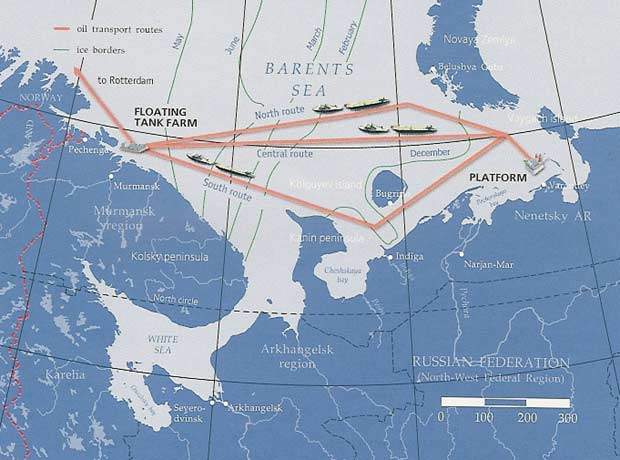

Oil transfer is carried out in two stages. The field was served until late 2015 by a 360,000t floating platform Belokamenka positioned in an ice-free part of Kola Bay. A new floating storage and offloading (FSO) vessel, Umba, replaced the Belokamenka in December 2015.

Oil from Prirazlomnoye is transferred to Umba FSO by ice breaking shuttle tankers of up to 220,000t. The crude is then be exported by up to four 150,000dwt to 170,000dwt supertankers. There are also two 16MW multifunctional icebreakers for assisting the tankers, as well as carrying out safety and environmental tasks. The platform is supported by a supply base at Arkhangelsk.