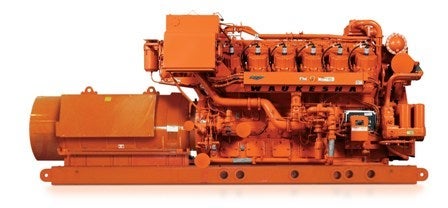

The US Environmental Protection Agency (EPA) has certified two of GE’s Waukesha natural gas engines for powering drill rigs and oilfield equipment.

The use of natural gas instead of diesel fuel in a drill rig is expected to reduce fuel costs by around 80%.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Patterson-UTI Drilling has replaced existing diesel systems with three Waukesha VHP L7044GSI gas engines at a well site in Harrison County, West Virginia, which received EPA permit exemptions. It also plans to replace additional diesel units with EPA-certified Waukesha L7044GSI-EPA engines at other locations in Ohio and Colorado.

Devon Energy has selected GE’s integrated Power to Lift solution, which includes the Waukesha L5794GSI natural gas engine that combines power and grid technologies. It will power electric submersible pump operations at the Mississippian formation near Oklahoma City.

Waukesha-Pearce Industries sales director Fred Stow said that the existing rig power generation drivers can be easily replaced with VHP L7044GSI-EPA and L5794GSI-EPA Waukesha gas engines.

"And it offers great cost advantages of natural gas versus diesel and dual-fuel, with natural gas available at less than half the price of diesel," Stow added.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData"Plus, you can reduce diesel transportation costs because the engine can run on a much greater variation of readily available fuel sources, using everything from dry field gas to pipeline gas, including LNG and propane."

Image: GE’s EPA-mobile certified Waukesha VHP L7044GSI-EPA natural gas engine. Photo: courtesy of GE.