Canada-based Domtar has inaugurated a commercial-scale lignin separation plant at its North Carolina mill in Plymouth, US.

Domtar said it is the first plant of this type in the US in over 25 years.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The company started BioChoice lignin production in February 2013, with a plan to produce 75t a day.

BioChoice can be used in different industrial applications, as a bio-based alternative of petroleum and other fossil fuels, resins and thermoplastics.

In 2010, the company launched a research and engineering project to install commercial-scale lignin removal capacity at the Plymouth mill.

The US Department of Agriculture and the US Department of Energy have provided a grant to the company for the Biomass Research and Development Initiative.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataDomtar research and development director, Bruno Marcoccia, said the company plans to partner with well known collaborators to develop new products, as well as to market a wide portfolio of initiatives such as BioChoice.

North Carolina State University Department of Forest Biomaterials professor Hasan Jameel said that providing manufacturers with a bio-based alternative to the use of petrochemicals will make a real difference.

"This is a big win for sustainability on two counts – Domtar improves the efficiency of its pulp-making process, and at the same time the market gets a reliable, high-quality source of this underused material with so much potential," Jameel added.

The high-quality lignin can be obtained as a by-product through kraft pulping process in the lignin removal facility, while about 1.1 million tonnes of lignin can be produced globally per year.

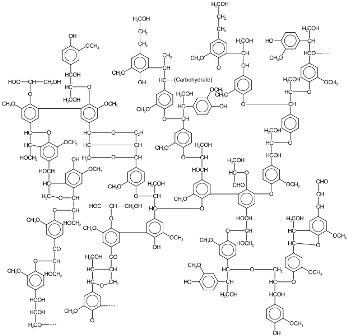

Image: Lignin structure. Photo: Courtesy of Karol Glab.