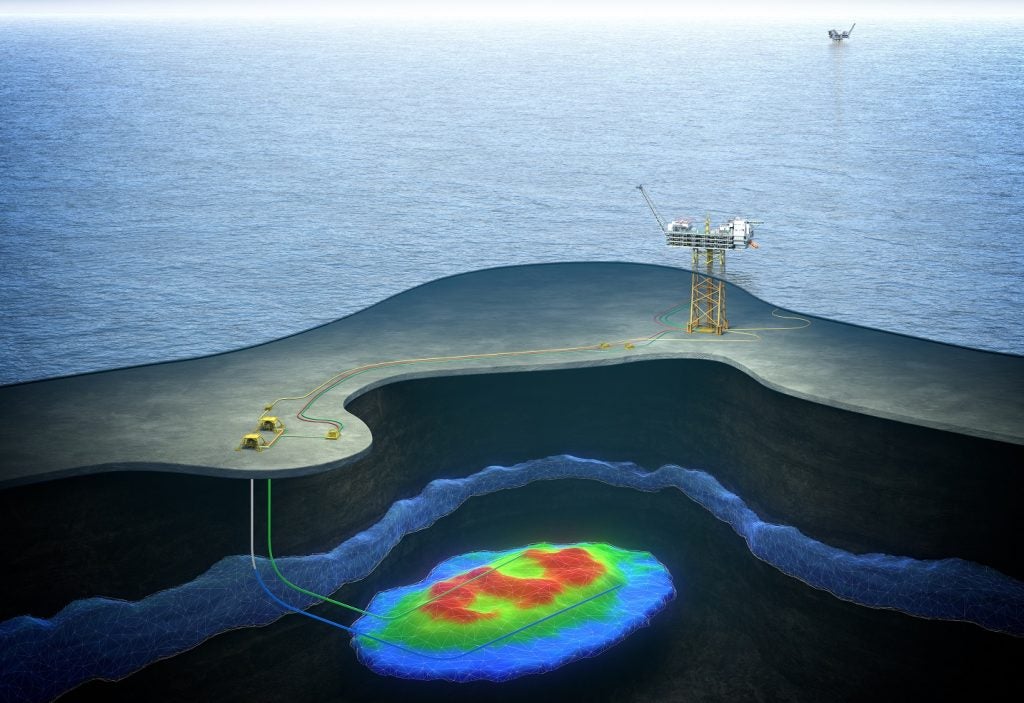

Being installed in highly corrosive environments, offshore oil and gas platforms and infrastructure require marine cathodic protection in the form of specialised coatings and preventive maintenance to extend the component service life and ensure operational safety. Corrosion detection methods are essential to quickly identify and address defects to prevent permanent damage to offshore structures.

Finding suppliers of marine cathodic protection, coating solutions and insulation products

Offshore Technology has listed leading providers of corrosion protection products, protective coating solutions, aluminium and zinc sacrificial anodes, corrosion inhibitors, and corrosion-resistant coatings, based on its intel, insights, and decades-long experience in the sector.

The list includes providers of corrosion detection methods, thermal and cryogenic insulation systems, flange protection products, cathodic protection systems, and galvanic protection solutions.

The information contained within the download document is designed for offshore corrosion protection technicians, corrosion control engineers, facility corrosion engineers, asset integrity engineers, and pipeline operations managers.

The download contains detailed information on the suppliers and their product lines, alongside contact details to aid your purchasing decisions.

See Also:

Corrosion prevention and marine cathodic protection solutions for offshore structures

Offshore structures and pipelines are vulnerable to internal and external corrosion. The flow efficiency in pipelines can be affected if internal corrosion prevention methods are not used.

Cathodic protection along with a high-efficiency protective coating is the most common corrosion protection solution used for offshore structures and pipelines.

Galvanic or sacrificial anode cathodic protection systems and impressed current systems are the two main types of cathodic protection solutions.

Fusion bond epoxy-based coatings, metal and thermal spray coatings, fibre-reinforced polymer coatings, abrasion-resistant coatings, glass flake coatings, and coatings containing polyurethanes and polysiloxanes are some of the commonly used protective coating solutions.

Corrosion prevention and protection can also be achieved using corrosion inhibitors and insulation products. Corrosion inhibitors are chemicals such as urotropine, thiourea and ruthenium, while insulation products are thermal-acoustic insulation systems and polymer-based covering materials.

Design criteria for choosing corrosion protection solutions

Several variables need to be considered before choosing the right corrosion protection solution for offshore oil and gas structures. The design criteria that need to be considered are:

- Operational life

- Dimensions of the offshore structures

- Geographic location

- Water depth

- Type of protective coating, and

- Installation method

Corrosion detection methods

Regular inspection and use of corrosion monitoring equipment can ensure corrosion prevention and avoid equipment failure.

Corrosion coupons, linear polarisation resistance, electrical resistance, and electrochemical impedance spectroscopy are considered destructive corrosion detection methods. Non-destructive methods include ultrasonic and acoustic testing, electromagnetic testing, magnetometer and di-electrometers, and magnetic flux leakage.