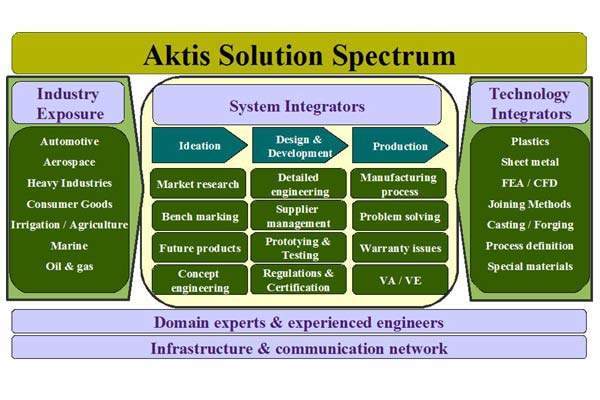

Aktis Engineering is a process-oriented engineering solutions company that specialises in the oil and gas, marine, automotive and aerospace industries. Aktis has a global presence and dedicated sales offices in Bangalore, London and Copenhagen.

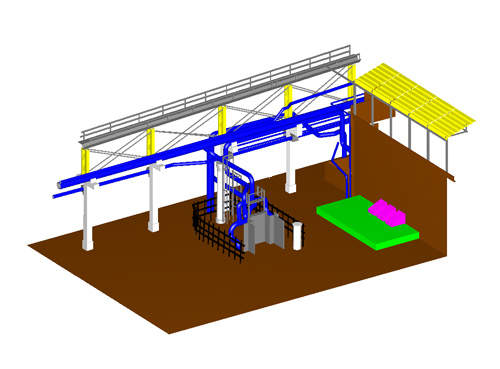

Upstream, downstream and midstream equipment

Aktis’ major areas of focus include providing engineering and product development solutions for the design and development of equipment used in the upstream, midstream and downstream activities. Aktis can contribute significantly to mechanical and process engineering activities.

Oil and gas design services and prototyping support

Aktis provides engineering support, design services and prototyping support to its clients across the oil and gas, power, energy and other areas of operations. In the oil and gas domain, Aktis has proven its presence in recent years by engaging with a market leader in the manufacturing of offshore and onshore sensor devices.

Manufacturing / prototype support for subsea sensors / leak detection devices

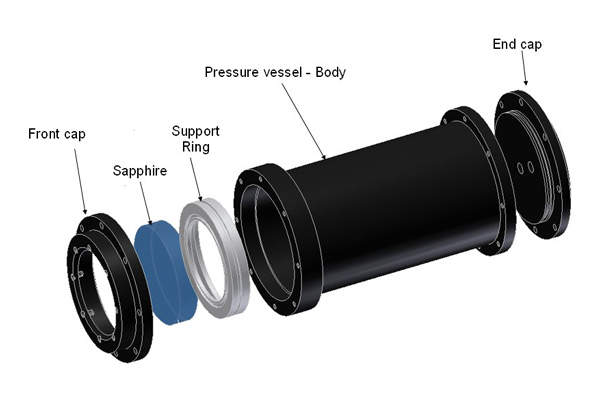

Smart Light Devices (SLD), UK, a specialist in the development of monitoring sensor products for use in subsea environments, is one of Aktis’ customers. Aktis is currently involved in providing high-quality and cost-effective prototype support to SLD for underwater sensor and detection systems such as laser leak detection (LLD), 3D scanner and laser smart pig.

Aktis has successfully delivered the prototype components for these systems at a very competitive cost and within a tight timeframe. Aktis uses its robust quality assurance process (right from material testing to the final prototype inspection) to ensure components manufactured meet the highest quality standards.

Aktis also has strong capabilities in design, analysis and re-engineering of complex mechanical components and systems to achieve technology enhancement, better product quality and durability. Aktis is being considered by SLD to undertake the design and analysis of components for underwater sensor devices such as design and validation of the outer casings for strength and leak proofing, design / analysis of internal components to ensure strength against shock loading.

Midstream and downstream value proposition

Aktis’ core services in the oil and gas industry are concentrated in the midstream and downstream activities. These include:

- Structural design and drawings (2D and 3D)

- Tool design and validation

- Piping design — pipe sizing, pipe routing, material selection and stability

- Machine design

- Accessory systems design and plant design

- Stress analysis — thermal and mechanical stresses for mechanical components

- Corrosion resistance technologies

- Re-design of equipment and machinery used for onshore and offshore activities; technology enhancement and better quality

- Ensuring statutory and procedural compliances for machinery and equipments

- CAD and CAE (FEA) for onshore and offshore equipment

Oil and gas mechanical equipment design and analysis

Aktis’ oil and gas experts have extensive experience in the design and analysis of a range of static, rotating and material handling equipment.

- Static equipment: pressure vessels, heat exchangers, tanks and filters, separators

- Rotating equipment: pumps, compressors, turbines and engines

- Material handling equipment: cranes, hoists and pulleys

Oil and gas reports, drawings and systematic documents

Aktis provides systematic documents to substantiate its activities in all the areas of operation. This provides customers with an easy reference for all the design activities at any given point of time. Aktis ensures detailed design reports, FMEA reports, FEA reports, material selection reports, drawings, technical queries, etc. are delivered at critical milestones.

Process engineering services for the offshore industry

Aktis offers process engineering services for the oil and gas industry. These include the following:

- Process design reports and process flow charts

- Participation in HSE studies and to learn prudent design changes

- Sizing calculations for equipment design

- Load calculations for sizing

- Data sheets for static and rotating equipment

- Data sheet for packaged items

- Equipment lists

- Area classification for hazardous material handling

- Preparing various technical as well as process manuals

Project-specific business and quality plans

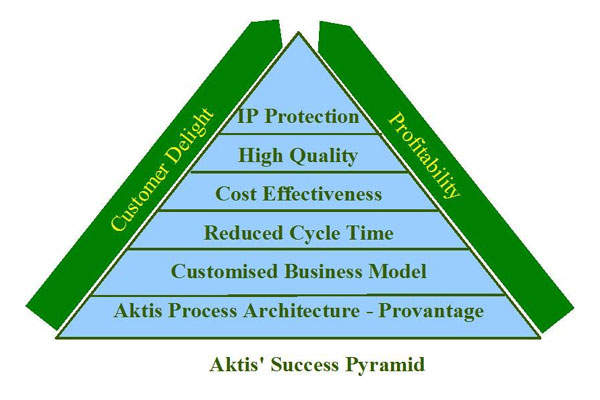

Aktis generates project-specific business and quality plans for all its customers. The plans are prepared to keep the focus on the client’s requirements so as to provide them with long-term visibility. All our services are carried out using trained, experienced and qualified personnel who have multiple years of experience in their respective domains.

Innovative oil and gas designs and technology

Aktis continuously strives towards developing technology-driven design solutions that will cater to next-generation products, thereby ensuring superiority for its customers in the operating space. With its specialists, Aktis is able to convert innovative design ideas into feasible design solutions.

Aktis provides unmatched business values to its customers through innovative and streamlined design solutions and quality frameworks.