CREA has been providing analysis of structures and systems subjected to extreme and hazard loads for over 12 years. Our engineers have been providing these services for over 25 years. Our analysis is typically used to substantiate requirements of quantitative risk analysis (QRA) and safety cases.

An extension of the use of advanced analysis is optimisation of designs to reduce the need for additional protection, an example being the reduction in passive fire protection following fire collapse studies. In the offshore design arena we would typically be called upon to examine blast and explosion response, and performance in fire. Our expertise includes other dynamic responses of structures, such as seismic and impact.

Extreme and hazard load analysis

Our main analysis tool is the industry standard large scale finite element analysis suite ANSYS. ANSYS has a proven track record stretching back to before 1980 and is authorised for use in many of the major safety related industries, particularly civil nuclear, defence and aerospace. At CREA we have 25 years of continuous experience with the program; and can exploit most of its structural analysis capabilities.

In addition to ANSYS we make use of the progressive collapse analysis program USFOS, developed by Sintef at the University of Trondheim. CREA has developed the necessary inter-operability tools to use the two side-by-side.

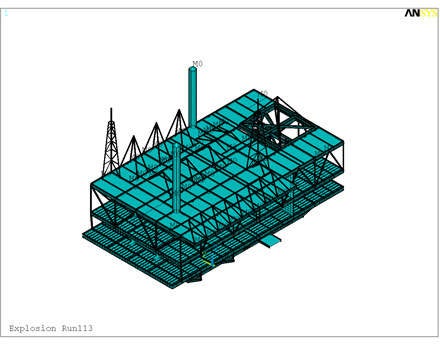

For a typical project CREA would aim to use our client’s own structural model developed with, for instance, SACS and convert this to the appropriate form for our modelling needs. This reduces quality assurance concerns and allows some validation against client results such as reaction forces and frequencies from the environmental studies.

All computer analysis is backed by hand calculation and simple analysis validation tests. CREA is committed to pursuing quality in analysis and is a major contributor to the international engineering simulation organisation NAFEMS.

Blast and explosion response analysis

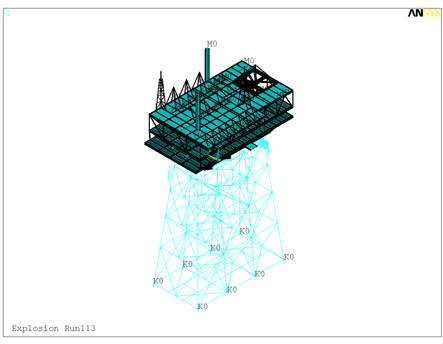

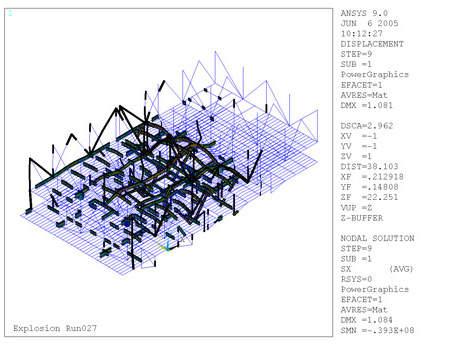

For blast or explosion response we can analyse structures either using a typical triangular pulse or we can take over-pressure time-histories from explosion over-pressure analysis carried out using computational fluid dynamics (CFD) analysis. CFD explosion prediction is not currently offered by CREA.

The over-pressures are then used to load a model of the structure to determine the structure’s non-linear response. The output is a prediction of the residual deformation of the structure and potential for the rupture of deck and wall boundaries.

In defining the model we would normally improve the modelling around the module being examined, as the design analysis is normally carried out on a coarser model than is usual for dynamic response. We are also able to model the loading onto major plant items with a view to examining the response of plant supports.

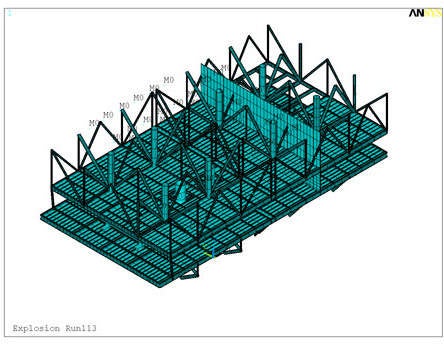

Blast wall analysis

Blast walls are capable of absorbing a great quantity of energy in deforming to resist explosion. This allows lighter structures to resist high over-pressures. A detailed analysis of the wall allows the weight to be optimised, and the residual deformations to be predicted; this in turn allows the effects on plants on the protected side of the wall to be assessed.

We can analyse blast walls using either peak over-pressure and typical over-pressure time profiles, or, as with the structure modelling, over-pressure time-histories from CFD or similar explosion modelling. We model the detailed wall separately from the structure analysis. However, we will commonly use the full structure model to predict the support response for the wall and hence improve the wall simulation.

Analysis of fire induced collapse of structures

Production facilities need to be protected against catastrophic collapse due to fire. However, local loss of structure away from safety critical areas or the temporary refuge can be permitted to fail. Once the facility has been safely evacuated, loss of structure becomes a protection of assets issue.

The facility QRA and safety case will define the length of time necessary for evacuation, and will predict the most likely significant fire scenarios. (It is rarely the most severe fire that leads to the worst case survivability). We take the fire scenarios and model the temperature distribution through the structure. These temperatures are then used in USFOS to predict the collapse mechanism. This enables us to proedict when regions of the structure will collapse.

This analysis type can be used to optimise fire protection schemes, principally passive schemes.