AC Fluid Technology specialises in hydraulic system controls. Offshore applications include Klotz particle counting systems to ISO4406 and NAS standards for the monitoring of drilling fluids and water systems for ships and rigs.

Our Buehler range includes the control and monitoring of liquids and gases with a particular emphasis on hydraulic, lubricant and coolant fluids — including ATEX, DNV and GL-certified controls. High-quality, robust Schneider servo valves have proved themselves in the extreme wind, rain, heat or sub-zero conditions encountered in shipping and offshore applications.

Particle counting, measuring and monitoring systems

Klotz laser particle measuring systems, certified to ISO4406 and NAS standards, are used for measuring particulate contamination in fluids.

A number of established offshore users test in such diverse applications as synthetic-based and water-based deepwater well drilling fluids and the commissioning of water systems in ships and rigs.

Examples of the diversity of other applications include:

- Testing hydraulic, lubrication and coolant fluids

- Contamination testing of power-generating and transformer-lubricating fluids

- Contamination testing of diesel and kerosene

- The monitoring of air in HVAC systems

- Testing drinking water and the purity of solutions in the pharmaceutical and chemical industries

- Determination of residual contamination in flushing and cleaning machinery during the machining of components

The logging of contamination may be determined continuously online or in the lab.

Offshore liquid level and temperature controls

Our comprehensive selection of level and temperature controls — with a well-established offshore user base — offer combined solutions for the control of liquid level and temperature, with switched or continuous analogue output.

Ruggedly designed — including an ATEX, DNV and GL-certified range — and having precise control and reliability, their many applications include hydraulic drive systems; hydraulic motor, power unit and control systems; variable speed power transmissions; and variable speed drives.

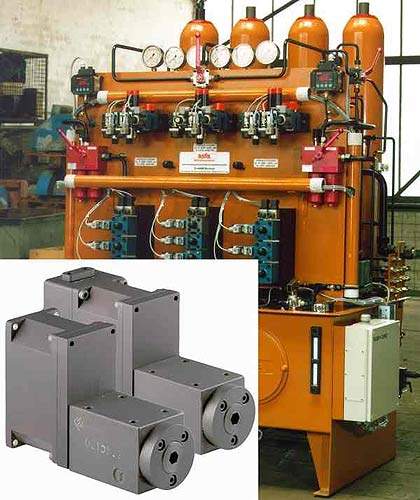

Fluid power, lubrication and coolant system controls

Highly integrated functions make for a very cost-effective solution for fluid power, lubrication and coolant system controls. The wide range of robust designs include ATEX, DNV and GL compliance, the ‘easyjust’ system unique to Bühler, a water-in-oil ingress alarm and a variety of electrical output options. We offer a wide range of standard products as well as custom designs for special needs.

Fluid control technology for hydraulic, lubrication and coolant systems

Investing in fluid power engineering achieves a long service life for fluids and components in hydraulic, lubrication and coolant systems. Fluid control technology achieves reduced energy consumption by controlling and stabilising a fluid’s operating temperature within a closely defined range.

Fluid control achieves a reduction of wear and tear in fluid power, lubrication and coolant systems by using advanced filtration and cooling methods. Fluid control reduces fluid waste by controlling leakage, which also enhances operational safety and protects the environment.

Servo valve technology

The servo valve is the heart of every electro-hydraulic control system. Conformance to static and dynamic parameters requires equipment of the highest quality.

The Schneider product range is widely used throughout the offshore oil and gas industry, and has proven itself in extreme conditions: whether in wind, rain, heat or sub-zero temperatures, Schneider’s robust systems work steadily and reliably. Schneider piston slide valves in single and multi-stage versions are subjected to stringent quality control.

The Schneider HVM servo valve range embraces single, two and three-stage valves having a flow rate ranging from 0.4l/min to 1,000l/min with pressures up to 420bar. Besides the standard range, application-related special valve designs are available, for example low-leakage pistons, two return flanges, and highly dynamic valves.