At present, only about a quarter of technically recoverable domestic oil resources in the USA are economically recoverable, even at today’s high oil prices. Finding a cost-effective method of recovering shallow oil is becoming an increasingly attractive proposition and micro-hole technology could be the solution.

Micro-hole drilling has the potential to greatly reduce the cost of drilling shallow and moderate-depth holes for exploration, field development, long-term subsurface monitoring and, to a limited degree, actual oil and gas production.

It also offers greatly enhanced reservoir imaging, making access to data cheaper and more precise, as well as being invaluable during exploration activities.

If costs can be reduced, oil and gas reservoirs that are uneconomic today could become economically viable. The Department of Energy (DOE) has launched a micro-hole initiative to assess the potential benefits to the USA and encourage research. It includes awarding companies promising breakthroughs in this field.

The main focus of US-based research is aimed at developing technologies to enable coiled tubing drilling of boreholes with a diameter of 3.5in or smaller using innovative, hybrid coiled tubing drill rigs.

See Also:

GREAT POTENTIAL

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataMicro-drilling technologies and micro-instrumentation are expected to benefit exploration activities and long-term reservoir monitoring as well as increase production by cutting expenses for rigtime, materials, labour and support equipment.

The fact that micro-hole technologies reduce the costs of overall operations makes exploration and production economically attractive to the independent operators that produce most of the USA’s domestic oil.

Micro-hole technology will allow independent operators to invest in a new wave of infill drilling of shallow development wells. Re-entering existing wells will also be possible, increasing production from bypassed zones and providing a reliable capability to deepen thousands of boreholes. This will encourage deeper exploration in existing fields because the top section has already been drilled.

These new low-cost production capabilities are needed to invigorate the domestic oil and gas industry so that more of the petroleum resources in the USA’s mature basins can be recovered.

The predicted reduction in materials, labour and support equipment could cut expenses in half when compared with drilling a conventional well and volumes of drilling fluids and cuttings could be lowered by one fifth, reducing disposal costs.

In addition, smaller footprints, reduced drilling waste and increased transportability for remote, fragile terrains will lessen the environmental impact of drilling activities, making micro-hole drilling applicable in environmentally sensitive areas.

Furthermore, overall coiled tubing drilling efficiency improvements could be applied to ultra-deepwater operations.

The economic and environmental benefits are expected to increase exploration and production activities, improving domestic oil and gas production and revenues from federal lands. At least 10% of the 218 billion barrels of oil in reservoirs less than 5,000ft deep could be recovered. This represents ten years of OPEC imports.

IMPROVING ACCESS TO INFORMATION

Micro-hole technology will also assist exploration and improve access to data on operating wells using economic seismic technologies for reservoir imaging.

Both exploration and assessment of current reservoirs will be greatly enhanced by high-resolution seismic imaging utilising MicroElectroMechanical (MEMS) technologies. This is expected to result in unprecedented seismic imaging using miniaturised sensors for high-resolution exploration methods.

Dedicated boreholes with permanent reservoir monitoring systems

will provide high-resolution, real-time information while monitoring and optimising improved oil recovery (IOR) processes. This low-cost, long-term, improved imaging method of monitoring fluids in the reservoir will enhance oil recovery and allow dedicated boreholes for reservoir monitoring, eliminating production interruptions.

This new-found geophysical capability utilising vertical seismic profiling (VSP) is referred to as ‘designer seismic’ because geophysicists will now be able to pick the location of the instrument package rather than using an existing well while production is shut in.

ONGOING RESEARCH

The micro-hole initiative was based in part on the miniaturisation of seismic sensors, micro-hole rig development and feasibility studies conducted by Los Alamos National Laboratory (LANL) and its industry partners. The feasibility study and demonstration of coiled tubing-deployed micro-drilling indicated that micro-holes could increase recovery from domestic oil and gas fields.

The first solicitation from the micro-hole initiative focused on field demonstrations and the technologies needed to employ coiled tubing micro-hole drilling in the field. This involved demonstrations of 4.75in commercial micro-hole technology and applications in selected regions of the USA.

A micro-hole coiled tubing rig has been designed and built that can drill 1in through 2.375in coiled tubing boreholes with low-density, compressible drilling fluids.

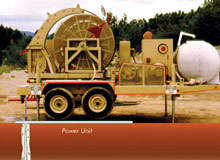

Micro-hole-specific mud systems that are truck-, trailer- or skid-mounted and meet USDOT regulations have also been developed. The mud system must be able to mix, circulate downhole, clean and hold diesel- or water-based drilling mud, and be compatible with an underbalanced drilling system.

Micro-hole coiled tubing bottomhole assemblies, including measurement while drilling, logging while drilling, directional assemblies and positive displacement motors suitable for drilling 3in boreholes, are also being tested. Meanwhile, completion and production equipment appropriate for ultra-small diameter boreholes are being developed.

With these developments, this is an exciting time for the oil industry, promising to reduce production costs, improve access to information and, most importantly, make the reclaiming of the USA’s huge resources of shallow oil a reality for the future.