The Banff field lies 25km south east of the Gannet accumulations in the Central North Sea, 200km east of Aberdeen, UK. It is located predominantly in the Conoco-operated block 29 / 2a, extending into the neighbouring block 22 / 27a operated by Ranger. Its reserves are estimated at between 20 million and 110 million barrels.

In October 2003, Canadian Natural Resources (CNR) took over Conoco’s share of interest in the field. As of July 2007, the partners of the field include CNR International (65.33%), CNR International Developments (22.28%) and Dana Petroleum (12.40%). CNR holds 26.2% working interest in the field through its subsidiary Ranger.

Banff reserves

The reservoir lies between 4,500ft and 7,600ft, and consists of Palaeocene sands underlying a steeply dipping and faulted Upper Cretaceous (Maastrichtian) chalk formation, located around a salt diapir piercement.

Earlier, the field was estimated to have reserves of about 60 million barrels of 38-39° API gravity oil and approximately 39 billion cubic feet of gas.

In 2007, the recoverable reserves were estimated to be 6.7 million tonnes of oil and 0.61 billion cubic metres of gas .

Drilling

After the exploration well, two appraisal wells were drilled (29 / 2a-7 in October 1991 and 29 / 2a-10 in December 1993).

Banff will be produced from two production wells (29 / 2a-B1 and 29 / 2a-B2), which were drilled and tested using the semisubmersible drilling rig Glomar Arctic III, and tested at a cumulative rate of 17,735bopd and 7 million cubic feet per day of gas.

Each of the wells encountered more than 3,000ft of hydrocarbon-bearing section in the chalk reservoir.

Production

In order to ascertain reservoir performance and prove its potential for further development, Conoco carried out a six-month production test using a floating production unit with a shuttle tanker offtake. The assessment began in September 1996.

The early production system was operated by the Turnkey Additional Production (TAP) Alliance, consisting of Schlumberger, Sedco Forex and Coflexip Stena. The test facilities comprised a floating production facility with the capability of processing up to a maximum of 35,000bopd flowing to a storage / shuttle tanker.

The Sedco 707 floating production semisubmersible drilling rig was modified to accommodate processing facilities with the associated risers and controls.

The subsea architecture consisted of two horizontal production trees supplied by FMC flowing to a production manifold via two four-inch flexible jumper flowlines. From the manifold, production flowed through a single six-inch dynamic riser to a riser platform at the stern of the Sedco 707.

Production started February 1999 with an early production rate ranging between 6,000 and 34,000bopd for an initial three days. Production was later stopped due to operational conditions with the leased Ramform FPSO.

The FPSO was removed from the field for repair and refitting in 2000. The repair work was completed and oil production restarted in March 2001.

The natural gas reinjecting programme to increase the reservoir’s recovery from the field was started in the fourth quarter of 2004.

Banff development

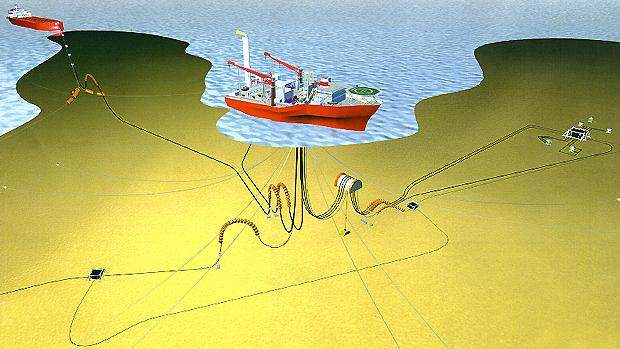

Banff is developed by a new floating production, storage and offtake (FPSO) system owned and operated by Petroleum Geo-Services UK Limited (PGS).

The production system, infield flowlines and gas-export pipeline were supplied by PGS under a production services contract with Conoco and its co-venturers. PGS owns the facilities with production operations sub-contracted to Atlantic Power.

In 1997, NKT Flexibles was given a contract by PGS Offshore Technology on behalf of Conoco to supply dynamic risers and static jumpers for the FPSO. The contract work also included detailed design, engineering, procurement, manufacturing, certification and testing.

The Banff field development is the first time the Ramform hull design has been used as a floating production system. The hull, which has a characteristic delta shape, provides both a large-load bearing capacity (of up to 16,000t) and a stable work platform, affording a compact alternative to a conventional parallel-sided tanker conversion.

The subsea wells are tied back to a five-well cluster manifold capable of expansion if required. Another field, Kyle, operated by CNR was tied to the FPSO in 1999-2000.

Contract

In December 2009, the contract for installing the replacement of subsea control modules and flexible jumpers for the field was given to Subsea 7.

FPSO

The newbuild double-hull production vessel was fabricated at the Hyundai Mipo yard in Ulsan, South Korea. It has a storage capacity of 120,000 barrels (onboard) plus an extra 500,000 barrels.

The vessel is 395ft long by 175ft wide. The ship’s weight, excluding the helideck and topsides modules, is approximately 8,000t.

The 3,500t topsides can process 60,000bopd and 90,000bpd of fluid. They also have the necessary facilities for gas dehydration, compression and export, water injection, produced water treatment and disposal, metering, stabilised crude export, utility systems, process / well control and shutdown systems.

Banff exports

Oil is exported via a double-hulled shuttle tanker in 500,000 barrel loads. The gas is exported through a 6in, 8km pipeline, which will tie-in to the 36in CATS trunkline.